What Is a TRIAC Dimmer? Working Principle, Applications, and Comparison Guide

What Is a TRIAC Dimmer?

Definition and Basic Function of a TRIAC Dimmer

A TRIAC dimmer is an AC circuit dimming device designed around a bidirectional thyristor (TRIAC) component. Its core function is to precisely control lighting brightness by adjusting the AC voltage's conduction phase. Its fundamental principle leverages the TRIAC's bidirectional conductivity to "capture" a portion of electrical energy during each half-cycle of the AC voltage. This alters the RMS value of the voltage waveform delivered to the lighting fixture, enabling seamless switching between different brightness levels.

In practical applications, triac dimmers not only enable continuous dimming (such as smooth adjustment from 10% to 100% brightness) but can also be paired with knobs, buttons, or intelligent control modules (like those compatible with Amazon Alexa) to meet manual or automated dimming needs. They are widely compatible with incandescent bulbs, halogen lamps, and certain compatible LED lights, making them one of the most cost-effective dimming solutions currently available for both residential and commercial lighting applications.

Differences Between Triac Dimmers and Conventional Dimmers

Conventional dimmers typically use methods such as "series resistor voltage division" or "transformer voltage regulation," whereas thyristor dimmers use "phase control" technology. The two differ significantly in core principles, performance, and applicable scenarios, as detailed in the comparison table below:

|

Comparison Dimensions |

Thyristor Dimmer |

Conventional Dimmer (Resistor Voltage-Splitting Type) |

|

Core Principle |

AC phase-cutting to regulate voltage conduction time |

A series resistor dissipates excess power, reducing the output voltage |

|

Power Loss |

Low (only minor losses occur during switching transitions) |

High (Resistors generate significant heat and consume substantial energy) |

|

Dimming range |

Wide (typically supports 10%-100% brightness adjustment) |

Narrow (prone to "light flickering at low brightness") |

|

Compatible loads |

Incandescent bulbs, halogen bulbs, and compatible LED bulbs |

Compatible only with low-power incandescent bulbs (not suitable for LED bulbs) |

|

Size and Installation |

Compact and lightweight, supports flush-mounted wall installation |

Larger size (requires space for high-power resistors), limited installation flexibility |

|

Cost |

Moderate (low cost of core component: thyristor) |

Low (simple structure) but high long-term energy consumption costs |

For example, in a North American home living room's main light dimming scenario, a thyristor dimmer enables smooth transitions from soft nightlight mode to bright illumination mode without noticeable heat generation. In contrast, conventional resistor-based dimmers continuously generate heat at low brightness levels, not only wasting energy but also posing safety hazards due to excessive temperatures.

Working Principle of Thyristor Dimmers

AC Phase-Cutting Control: Leading Edge vs. Trailing Edge

The core technology of thyristor dimmers is "AC phase-cutting control." This involves controlling the thyristor's conduction timing to "cut off" portions of the waveform in each half-cycle (positive and negative) of the AC voltage. This alters the RMS value of the output voltage, thereby adjusting the light's brightness. Based on the phase-cutting method, it can be categorized into two types: Leading-Edge Phase-Cutting and Trailing-Edge Phase-Cutting:

- Leading-Edge Phase Cutting: At the start of the AC voltage half-cycle, the thyristor remains off, "cutting off" the first half of the voltage waveform. After reaching the set conduction time, the thyristor turns on, allowing the second half of the voltage waveform to pass to the load. This method offers fast response times and is suitable for controlling resistive loads, such as incandescent or halogen lamps. However, it has poor compatibility with capacitive loads, such as LED lamps, which can cause flickering or noise.

- Trailing-Edge Phase Cutting: At the start of the AC voltage half-cycle, the thyristor remains on, allowing the first half of the voltage waveform to pass normally. As the half-cycle nears completion, the thyristor turns off, "cutting off" the latter half of the voltage waveform. Its advantage lies in better compatibility with capacitive loads, such as LED and compact fluorescent lamps (CFLs), offering smoother dimming with reduced flicker risk. This is currently the mainstream thyristor dimming method in LED lighting systems.

How Thyristors Control Voltage and Current

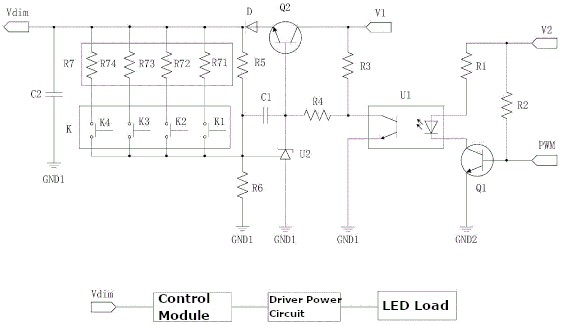

A triac (TRIAC) is a bidirectional three-terminal semiconductor device with the characteristic of "continuing conduction after triggering until the current crosses zero before turning off." The process of controlling voltage and current can be divided into three key stages:

- Triggering and Conduction Phase: When the dimmer's triggering circuit (such as a DIAC) injects a small trigger current into the TRIAC's "gate," the TRIAC immediately conducts, allowing alternating current to flow bidirectionally (during both the positive and negative half-cycles). At this point, the voltage and current delivered to the lamp depend on the timing of conduction—earlier conduction yields higher rms voltage and brighter light; later conduction yields lower rms voltage and dimmer light.

- Continuous Conduction Phase: After the thyristor conducts, it remains conducting even if the gate trigger current is removed, until the AC naturally crosses zero (i.e., when the instantaneous current is zero at the end of an AC voltage or current half-cycle). This characteristic ensures continuity of current in the AC circuit, preventing light flickering caused by frequent current interruptions during dimming.

- Turn-off and Cycle Phase: After the AC crosses zero, the thyristor automatically turns off and returns to its initial trigger-ready state. When the next voltage half-cycle begins, the trigger circuit reapplies trigger current to the gate, repeating the "turn-on - conduction - turn-off" cycle to achieve continuous dimming control.

Using 220V/50Hz mains power as an example(note: North America and other regions use 120V/60Hz), the AC voltage experiences (for 50Hz) or 60 (for 60Hz) positive half-cycles and (for 50Hz) or 60 (for 60Hz) negative half-cycles per second. The thyristor completes 100-120 "trigger-conduct-turn-off" cycles per second. Due to the human eye's persistence of vision, subtle changes in light intensity are imperceptible, resulting in a stable brightness adjustment.

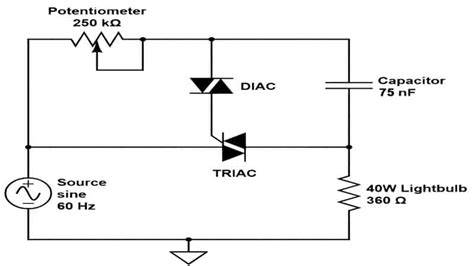

Core Components: DIAC, Trigger Gate, Load Response

The stable operation of a thyristor dimmer relies on the coordinated function of three core components. Their respective roles and impact on dimming performance are as follows:

- DIAC (Diode for Alternating Current) or Bidirectional Diode Switch: As the core of the triggering circuit, the DIAC possesses "bidirectional breakdown conduction" characteristics. When the voltage across its terminals reaches the set threshold (typically 20-40V), it automatically conducts and supplies a trigger current to the thyristor gate. Its function is to ensure symmetry in the trigger signal, preventing light flicker caused by inconsistent conduction times during the positive and negative half-cycles of AC. It also simplifies circuit design and reduces costs.

- Trigger Gate: The control terminal of the thyristor, which receives the trigger current output from the DIAC to control the conduction timing. The gate's trigger sensitivity directly affects dimming accuracy—excessive sensitivity may cause false triggering due to grid interference, leading to brightness jumps; insufficient sensitivity may cause trigger delays and slower dimming response.

- Load Response: The adaptability of the luminaire (load) to the thyristor's output voltage. Response characteristics vary significantly among different load types:

-

- Incandescent and halogen lamps: Pure resistive loads with linear current-voltage relationships. They respond stably to thyristor dimming with minimal compatibility issues.

- LED lamps: These are nonlinear loads. Their internal driver design causes them to often present as capacitive loads to the dimmer. Their internal driver circuits are sensitive to voltage changes. If incompatible with the triac dimmer, issues such as "low-brightness flickering," "narrow brightness adjustment range," or "high-frequency noise" may occur. led driver power supplies labeled "triac compatible" must be selected.

- Incandescent and halogen lamps: Pure resistive loads with linear current-voltage relationships. They respond stably to thyristor dimming with minimal compatibility issues.

Triac Dimming and LED Drivers

Why Don't All LED/Drivers Lamps Support Triac Dimming

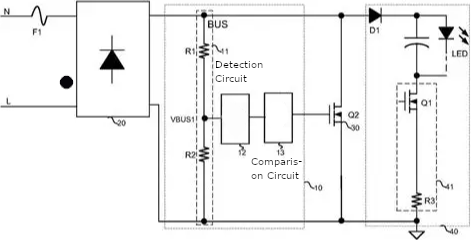

LED dimming principles differ from those of traditional incandescent bulbs—incandescent bulbs adjust brightness directly by changing the voltage. At the same time, LEDs require an LED driver to convert AC voltage to DC before controlling brightness via current regulation. Therefore, whether an LED dimmer supports triac dimming depends on its driver design, primarily due to:

- Load Characteristic Mismatch: Most standard LED drivers employ "constant current drive," which demands high input-voltage stability. Triac dimmers output "phase-cut non-sinusoidal voltage." If the driver lacks phase-cut voltage-adaptation circuitry, output current fluctuations occur, leading to LED flicker.

- Minimum load current requirement: A triac dimmer must meet a certain minimum load current to operate stably (typically requiring minimum load power; traditional dimmers demand a minimum load current of approximately 5-20mA). LEDs operate at lower currents (e.g., 20-300mA per LED). If the total current from multiple parallel LEDs remains below the dimmer's minimum threshold, the thyristor may fail to trigger properly, causing "flickering lights" or "dimming failure."

- EMI Interference Suppression Capability: Triac dimming generates high-frequency electromagnetic interference (EMI). If standard LED drivers lack EMI filtering circuits, this interference can disrupt the driver chip's operation, causing unstable output current and exacerbating light flickering.

Are all LED dimmers thyristor-based?

The answer is no. LED dimming technologies vary widely, with triac dimmers being just one type. Current mainstream LED dimming technologies include 0-10V, PWM, and DALI dimming. The principles and suitable applications of these different technologies differ significantly:

- Triac Dimmers: Based on phase-cutting technology, they require no additional signal wires and can directly replace traditional incandescent dimmers. With low installation costs, they are well-suited for retrofit lighting applications in homes and hotels. However, their dimming range and compatibility are limited by load constraints.

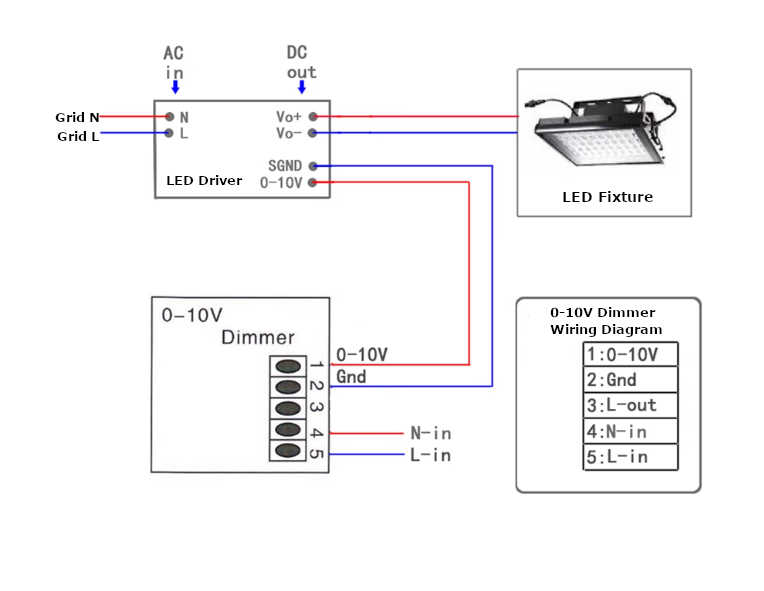

- 0-10V Dimmers: Control LED drivers via an additional 0-10V DC signal wire. 0V corresponds to minimum brightness, while 10V corresponds to maximum brightness. They offer a wide dimming range (1%-100%), flicker-free operation, and are suitable for large commercial lighting systems in malls, office buildings, and other applications. However, they require additional wiring, which increases installation costs.

- PWM Dimmer: Controls LED conduction time via high-frequency pulse width modulation (e.g., 1kHz-20kHz) to adjust brightness. Offers high dimming precision and flicker-free operation, making it suitable for applications that demand precise brightness control, such as displays and automotive lighting. However, it requires a high-frequency response from the driver chip, which increases costs.

Therefore, whether an LED dimmer is a triac dimmer must be determined based on its core technical principle and cannot be generalized.

How to Match a TRIAC Dimmer with a Suitable LED Driver

To ensure compatibility between TRIAC dimmers and LED lamps, matching must be performed across three dimensions: LED driver selection, parameter alignment, and testing/validation. The specific steps are as follows:

Step 1. Select a "TRIAC-Compatible" LED Driver

Prioritize LED drivers labeled "TRIAC Dimmable" or "TRIAC Compatible" in product specifications. These drivers typically incorporate "phase-cut voltage detection circuits," "minimum load compensation circuits," and "EMI filtering circuits," resolving compatibility issues between standard drivers and TRIAC dimmers.

Step 2. Match Key Parameters

- Input Voltage Range: Ensure the LED driver's input voltage range matches the TRIAC dimmer's output voltage (e.g., AC 100-240V drivers for universal voltage dimmers).

- Output Current / Power: The driver's output current must match the LED light's rated current (e.g., a 300 mA driver for LED strips rated at 300 mA). Additionally, the driver's rated power must exceed the total power consumption of the LED lights (allow a 10%-20% margin to prevent overload).

- Minimum Load Current: The minimum input current to the load (LED driver) must be higher than the minimum load current (or sustaining current) required by the TRIAC dimmer to ensure that the dimmer can trigger and maintain conduction stably.

Step 3. Compatibility Verification Test

- Brightness Adjustment Test: Connect the LED lamp, triac dimmer, and compatible driver. Adjust the dimmer knob to observe whether the light transitions smoothly from minimum to maximum brightness without flickering, sudden changes, or extinguishing.

- Stability Test: Operate continuously at the lowest brightness setting for 30 minutes. Check for "thermal flicker" (brightness fluctuations caused by temperature changes) in the LED light, and ensure the driver's surface temperature remains within normal limits (no more than 60°C).

- Noise Test: Listen closely to the fixture during dimming. Ensure there is no noticeable high-frequency noise (e.g., "hissing") that would disrupt daily life.

Advantages and Disadvantages of Triac Dimming

Advantages: Low cost, simple wiring, suitable for retrofits

Thyristor dimming technology maintains a significant presence in lighting due to its mature design and adaptability, with core advantages in three areas:

- High cost-effectiveness: The core components of thyristor dimmers (thyristors, DIACs) have low production costs, and the circuit structure is simple (requiring no complex digital control chips or additional signal wires). The end-product price is only 1/3 to 1/2 that of comparable digital dimmers, making it suitable for large-scale residential and commercial deployment. For example, a household wall-mounted thyristor dimmer typically costs $8–15, significantly lower than a DALI dimmer of comparable specifications ($30–75).

- Simple wiring and flexible installation: Thyristor dimmers use "series wiring," requiring only a connection between the light fixture and mains power—no additional control wiring is needed (unlike 0-10V dimmers, which require separate signal cables). Installation follows standard switch procedures. This feature makes it particularly suitable for "retrofitting existing lighting systems". For example, directly replacing a home's original incandescent light switch with a triac dimmer enables dimming functionality without altering the existing wiring.

- Compatible with traditional loads and highly adaptable: Thyristor dimmers offer nearly 100% compatibility with conventional incandescent and halogen lamps, requiring no additional adapters for direct use. Furthermore, with the widespread adoption of "thyristor-compatible LED drivers," they can also accommodate most modern LED lighting products, achieving "universal compatibility with both old and new loads" and reducing user costs when upgrading lighting equipment.

Disadvantages: Potential flickering and limited dimming range

Despite their apparent advantages, thyristor dimmers have inherent limitations due to their technical principles:

- Risk of light flicker: Triac dimming alters voltage waveforms through "phase-cutting." Poor compatibility with nonlinear loads, such as LEDs, can cause output current fluctuations, leading to light flicker (especially at low brightness levels). While this flicker may be imperceptible to the naked eye, prolonged exposure can increase visual fatigue and affect eye health. For example, LED downlights not labeled "triac-compatible" may exhibit noticeable flickering at brightness levels below 30% when paired with standard leading-edge phase-cut dimmers.

- Limited dimming range: The minimum brightness achievable with triac dimmers is constrained by "minimum conduction time" and "load characteristics," typically preventing "zero brightness" adjustment. The lowest achievable brightness is usually between 5% and 10%. In contrast, PWM dimmers offer a wide 1%-100% dimming range and even support an "ultra-low brightness mode" (below 1%), making them more suitable for scenarios that demand high brightness precision (e.g., theaters, laboratories).

- Grid Interference: High-frequency harmonics generated during triac turn-on and turn-off cycles are injected into the power grid, potentially interfering with other electronic devices (e.g., causing static in televisions or radios). Although modern triac dimmers incorporate built-in filtering circuits to reduce interference, complete elimination remains impossible. Caution is advised in environments with stringent electromagnetic compatibility (EMC) requirements (e.g., hospitals, precision laboratories).

Why Engineers Still Choose TRIAC Dimming

Despite drawbacks like flicker and limited dimming range, engineers prioritize TRIAC dimming solutions in residential and commercial lighting applications for key reasons:

- High market penetration and mature supply chain: TRIAC dimming technology has evolved over decades, with a highly mature supply chain spanning component production to end-product manufacturing. Product stability is validated over long-term use, featuring low failure rates (typically below 0.5%). Engineers need not worry about "mass failures due to immature new technology," reducing project risks.

- Compatibility with existing wiring systems and low retrofit costs: Most global buildings still use traditional "single-wire" or "live wire + neutral wire" lighting wiring systems. Thyristor dimmers can directly replace existing switches without additional wiring, resulting in retrofit costs that are only 1/5 to 1/3 those of 0-10V dimming systems. For operational buildings like hotels and office towers, choosing thyristor dimming avoids the extended timelines and increased costs associated with "wall demolition and rewiring."

- User Habit Compatibility: Thyristor dimmers operate identically to traditional switches (e.g., knob dimming, button dimming), requiring no new learning curve and ensuring high user acceptance. For instance, residential users can intuitively adjust brightness by rotating a knob without needing smartphone apps or specialized controllers—ideal for elderly users or those unfamiliar with smart devices.

SCR Dimming vs. 0-10V vs. PWM Dimming

Control Mechanism Comparison

The core differences between triac dimming, 0-10V dimming, and PWM dimming lie in their control mechanisms. These mechanisms determine their applicable scenarios and performance characteristics, as detailed below:

|

Dimming Type |

Control Mechanism |

Core Component / Circuit |

Signal Transmission Method |

|

Thyristor Dimming |

AC Phase Control (Leading Edge / Trailing Edge) |

Triac (TRIAC), DIAC Triggering Diode |

No additional signal wires; phase-cut voltage transmitted via the mains power line |

|

0-10V Dimming |

DC voltage signal control |

0-10V signal generator, LED driver, Built-in voltage detection circuit |

Requires separate installation of a 2-core signal cable (for transmitting a 0- 10V DC signal) |

|

PWM dimming |

Pulse Width Modulation Control |

Microcontroller (MCU), PWM signal generator, LED driver with built-in current regulation circuit |

PWM signals can be transmitted via wired, wireless (Bluetooth/Wi-Fi), or DMX512 bus |

Example: "Adjusting LED Strip Brightness"

- TRIAC Dimming: Adjusts mains voltage by phase-cutting to directly control the input voltage to the strip driver, thereby regulating output current;

- 0-10V dimming: Sends a 2V DC signal (corresponding to 30% brightness) or an 8V DC signal (corresponding to 80% brightness) to the strip driver via the signal line; the driver adjusts the output current based on the signal voltage.

- PWM Dimming: A microcontroller sends a 50% duty cycle PWM signal (1kHz frequency). Upon receiving the signal, the driver rapidly switches the LEDs between "on" and "off" states, reducing the average current by 50% to achieve half brightness.

Performance and Compatibility Comparison Table

The three dimming methods exhibit significant differences in key performance metrics such as dimming range, compatibility, and stability, as detailed in the table below:

|

Performance Metric |

Triac Dimming |

0-10V Dimming |

PWM Dimming |

|

Dimming Range |

5%-100% |

1%-100% |

1%-100% (0.1%-100% technically feasible) |

|

Flicker Risk |

Moderate (LED lights may flicker; requires a compatible driver) |

Low (DC signal control, no phase-cutting interference) |

Extremely low (High-frequency pulses imperceptible to the human eye) |

|

Load Compatibility |

Incandescent/Halogen lamps (100% compatible); LED lamps (requires a compatible driver) |

Compatible only with 0-10V compatible LED/CFL drivers |

LED lamps (100% compatible); incandescent lamps (not applicable) |

|

Dimming Accuracy |

Medium (knob adjustment, no precise brightness steps) |

High (precisely configurable voltage values via signal generator, e.g., 3.5V corresponds to 35% brightness) |

Extremely high (precisely controls pulse duty cycle, e.g., 10.5% duty cycle corresponds to 10.5% brightness) |

|

Interference Resistance |

Low (Prone to grid harmonic interference) |

Medium (Signal lines susceptible to electromagnetic interference, shielding required) |

Strong (Digital signal transmission provides robust interference resistance) |

|

Multi-light synchronous control |

Difficult (Single-channel dimmer controls only one load; synchronization requires complex interlocking circuits) |

Easy (Single signal generator controls multiple 0-10V drivers for synchronized dimming) |

Extremely easy (Bus or wireless signals enable simultaneous control of hundreds of loads) |

Which dimming method best suits your lighting fixtures?

Selecting a dimming method requires considering three core factors: "fixture type," "application scenario," and "budget." Specific recommendations are as follows:

- Scenario 1: For home incandescent/halogen bulb retrofits with limited budgets, prioritize triac dimming: No fixture replacement needed—swap out the existing switch. Low cost, easy installation, and meets basic brightness adjustment needs (e.g., bedroom bedside lamps, living room main lights).

- Scenario 2: For large-scale commercial LED lighting systems in malls, office buildings, etc., 0-10V dimming is recommended: Offers wide dimming range (1%-100%), supports synchronized control of multiple fixtures (e.g., adjusting brightness of an entire floor's LED downlights simultaneously), ensures high stability, and integrates with Building Automation Systems (BAS) for scheduled dimming (e.g., 100% brightness during work hours, 30% after hours).

- Scenario 3: PWM dimming is essential for applications requiring high brightness precision (e.g., cinemas, laboratories, display screens): Extremely precise dimming (supports 0.1% brightness adjustment), eliminates flicker risk, and enables complex dimming logic through programming (e.g., cinema projection where lighting smoothly transitions from 100% to 1% without visual fluctuations). Additionally, PWM dimming supports wireless control, making it suitable for imaginative lighting scenarios (e.g., adjusting LED strip colors and brightness via a mobile app).

- Scenario 4: Mixed loads (incandescent and LED lighting) Select triac dimming: Compatible with both incandescent bulbs (direct control) and "triac-compatible LEDs" (paired with compatible drivers). Eliminates the need for separate dimming systems for different loads, reducing overall costs.

Common Applications of Triac Dimming

Residential Lighting Systems

In-home lighting: triac dimmers are primarily used in scenarios that require flexible brightness adjustment to adapt the lighting ambiance to different lifestyle needs. Typical applications include:

- Bedroom Lighting: Pairing bedside wall lamps with triac dimmers allows adjusting brightness to 10%-20% (soft nightlight mode) before sleep to avoid eye strain from harsh light. When rising at night, set brightness to 30%-50% for clear visibility without disturbing others.

- Living Room Lighting: Main fixtures (e.g., crystal chandeliers, ceiling lights) paired with triac dimmers can be set to 80%-100% brightness during daily activities like reading or watching TV. For gatherings or home theater mode, dim to 20%-40% to create a cozy ambiance.

- Kitchen and Bathroom Lighting: Adjust the brightness of LED task lights above kitchen countertops via triac dimmers. Set to 100% during food prep (ensuring clear vision to prevent cuts) and 50%-60% while washing dishes (energy-efficient and glare-free). Bathroom vanity lights should be set to 70%-80% brightness to minimize facial shadows, facilitating makeup application or shaving.

Taking a "modern minimalist home decor" style as an example, choose a white wall-mounted triac dimmer (such as the Lutron Maestro series). It connects it in series between the leading living room light and the mains power supply? Brightness adjustment is achieved via a rotary knob, eliminating the need for additional wiring. This seamlessly integrates with the overall decor style while meeting diverse lighting needs.

Architectural and Commercial Lighting Control

In building exterior lighting and commercial spaces, triac dimmers leverage their "low-cost, easy-integration" advantages for dynamic lighting effects and energy-saving control. Key applications include:

- Building Facade Lighting: Hotels and office buildings employ triac dimming systems for exterior LED contour lights and wall-washing fixtures. Centralized controllers synchronize brightness adjustments across multiple fixtures to create dynamic effects such as "fade" or "breathing" (e.g., gradually reducing brightness from 100% to 30% at night to minimize light pollution and energy consumption). For instance, a five-star hotel employs leading-edge phase-cut thyristor dimming for its wall-washing fixtures. Combined with timers, this system activates at sunset and deactivates at sunrise, while reducing brightness by 10% every two hours overnight, achieving average daily energy savings of 25%.

- Mall and Clothing Store Lighting: Spotlights in mall display windows and fitting room lights in clothing stores use triac dimmers to adjust brightness based on product characteristics and customer needs. For showcasing jewelry and cosmetics, brightness is set to 80%-100% (emphasizing product details). In fitting rooms, brightness is adjusted to 60%-70% (simulating natural daylight to prevent mismatches between try-on results and actual appearance). Additionally, some malls integrate thyristor dimming with motion sensors: brightness drops to 30% when unoccupied and returns to 100% when occupied, achieving energy savings.

- Restaurant and Café Lighting: Pendant lights over tables in Western restaurants and cafés are paired with silicon-controlled rectifier (SCR) dimmers. During dinner service, brightness is adjusted to 30%-50% (creating a warm, romantic ambiance); during lunch service, it is set to 70%-80% (ensuring clear visibility for dining). Some high-end restaurants also employ "zone dimming," where separate areas (e.g., bar, private rooms, main hall) are adjusted via independent triac dimmers to create distinct lighting atmospheres.

Consumer Electronics and Smart Home Integration

With the advancement of smart home technology, triac dimmers are increasingly integrated with consumer electronics and intelligent control systems to enable "automated, remote" control. Typical applications include:

- Smart Switch Integration: Connecting triac dimmers with voice assistants (e.g., Amazon Alexa, Xiaomi Xiaoai) to adjust brightness via voice commands (e.g., "Xiaoai, dim the living room lights to 50%"). Simultaneously supports remote control via mobile apps, allowing users to dim lights to 10% while away (to simulate occupancy for security).

- Consumer Electronics Integration: In home theater systems, the dimmer synchronizes with projectors and audio equipment—lights automatically dim from 100% to 10% when the projector turns on, and return to 80% when it turns off, eliminating manual adjustments. Additionally, select gaming consoles (e.g., Xbox, PlayStation) support integration with the triac dimmer. During gameplay, ambient lighting automatically adjusts based on screen brightness (e.g., dimmed to 30% for dark-toned games; brightened to 60% for light-toned games), enhancing immersion.

- Sensors and Automated Control: Combining triac dimmers with light sensors and motion detectors enables "environmentally adaptive dimming." During daylight hours with ample natural light, lighting automatically adjusts to 30%-50%; at night with insufficient natural light, it adjusts to 70%-80%; and when no activity is detected, it switches to 10% energy-saving mode. This automated control is widely applied in entryways, hallways, balconies, and similar spaces, enhancing convenience while reducing energy consumption.

How to Choose the Right Thyristor Dimmer

Are Lutron dimmers triac dimmers?

Lutron is a globally renowned lighting control brand. Its product line includes TRIAC, 0-10V, and DALI dimmers. Not all Lutron dimmers are TRIAC dimmers; determination requires reference to specific product series:

- Lutron TRIAC Dimmer Series: Examples include the Maestro and Diva series. These incorporate TRIACs as core components, supporting leading-edge or trailing-edge phase-cut dimming. They are compatible with incandescent, Halogen, and TRIAC-compatible LED lamps, primarily serving residential and small commercial applications. For example, the Lutron Maestro MACL-153M-WH dimmer supports 120V voltage with a 10%-100% dimming range, adjustable via a rotary knob, making it a typical TRIAC dimmer.

- Lutron Non-Triac Dimmers Series: Series such as Quantum and EcoSystem use 0-10V or DALI digital control technology, supporting centralized control of large-scale lighting systems. Primarily used in large shopping malls, hotels, and office buildings. For example, the Lutron Quantum QS series dimmer controls multiple LED drivers via a 0-10V signal line, enabling 1%-100% wide-range dimming, and is not a TRIAC dimmer.

Therefore, to determine if a Lutron dimmer is a TRIAC type, check the "Dimming Technology" or "Load Compatibility" section in the product specification sheet. If labeled "TRIAC Dimming," " Phase-Cut Control," or "Compatible with Incandescent/Halogen/LED (TRIAC)," it is a TRIAC dimmer. If labeled "0-10V Dimming" or "DALI Dimming," it is a non-TRIAC dimmer.

Compatibility Check and Testing Techniques

When selecting a TRIAC dimmer, ensure compatibility with the luminaire by following two steps—"Parameter Matching" and "Compatibility Testing"—to prevent issues such as flickering or failure to dim. The specific methods are as follows:

Compatibility Check: Matching Three Core Parameters

-

Voltage and Power Matching

-

- Input Voltage: The dimmer's input voltage must match the mains voltage (e.g., select AC 220V dimmers for the Chinese market, AC 120V dimmers for the US market) to prevent a voltage mismatch that could damage the dimmer.

- Rated Power: The dimmer's rated power must exceed the total control of the lighting fixtures, with a 10%-20% margin. For example, three 10W LED downlights with a total power of 30W require a triac dimmer rated ≥36W (30W × 1.2 = 36W).

- Input Voltage: The dimmer's input voltage must match the mains voltage (e.g., select AC 220V dimmers for the Chinese market, AC 120V dimmers for the US market) to prevent a voltage mismatch that could damage the dimmer.

-

Load Type Matching

-

- Resistive loads (incandescent, halogen lamps): Select leading-edge phase-cut triac dimmers for fast response and good compatibility.

- Capacitive loads (LED lamps, CFL lamps): Select trailing-edge phase-cut triac dimmers and ensure the dimmer is labeled "LED Compatible" to prevent flickering;

- Mixed loads (incandescent + LED lamps): Select a "dual-mode" triac dimmer (supporting automatic leading/trailing edge switching), such as unikeyic UK-TRIAC-DIM-01, to accommodate both load types simultaneously.

- Resistive loads (incandescent, halogen lamps): Select leading-edge phase-cut triac dimmers for fast response and good compatibility.

Minimum Load Current Matching

The dimmer's minimum load current must be ≤ the total minimum maintenance current of the lighting fixtures to prevent failure to trigger conduction due to insufficient load current. For example: - If the dimmer's minimum load current is five mA and three LED downlights each require a minimum operating current of 2 mA, the total minimum current is six mA (≥ five mA), making it compatible. If the minimum current per lamp is one mA, the total minimum current is three mA (< 5 mA). In this case, an additional "load compensation resistor" (e.g., 100Ω/10W resistor) must be connected in parallel to increase the total current above 5mA.

Compatibility Test: Four-Step Verification of Dimming Effect

- No-Load Power-On Test: Connect the dimmer alone to mains power (without any lights attached). After powering on, observe whether the dimmer's indicator light (if present) illuminates normally. When adjusting the knob, ensure there is no abnormal noise (e.g., a "hissing sound") indicating that the dimmer itself is functioning correctly.

- Single-Lamp Compatibility Test: Connect one lamp (e.g., LED downlight) in series with the dimmer. After powering on, adjust the knob and observe:

-

- Brightness Adjustment: From lowest to highest brightness, ensure smooth transitions without jumps, flickering, or sudden shutdowns.

- Low-Brightness Stability: Operate continuously at the lowest brightness setting (e.g., 10%) for 10 minutes. The light should not exhibit "flickering" or "flashing" behavior.

- Noise Check: Place near the fixture and dimmer; no high-frequency noise or electrical hum should be audible.

- Brightness Adjustment: From lowest to highest brightness, ensure smooth transitions without jumps, flickering, or sudden shutdowns.

- Multi-light synchronization test: Connect all lamps to be controlled (e.g., 5 LED spotlights) in series with the dimmer. Repeat single-lamp test steps, focusing on "stability during simultaneous operation of multiple lamps." If some lamps flicker, this may indicate insufficient total load current or non-triac-compatible lamps. Replace the lamps or add load-compensation resistors.

- Long-Term Stability Test: Keep the fixtures and dimmer powered on (e.g., continuous operation for 24 hours). Adjust brightness every 4 hours during this period and observe:

-

- Temperature: Surface temperatures of the dimmer and lamps must not exceed 60°C (measured with an infrared thermometer), with no signs of overheating;

- Functionality: Brightness adjustment functions normally without "dimming failure" or "brightness lock" issues.

- Temperature: Surface temperatures of the dimmer and lamps must not exceed 60°C (measured with an infrared thermometer), with no signs of overheating;

Unikeyic Recommended TRIAC Components and Driver Solutions

As an electronic component supplier, Unikeyic provides TRIAC dimmer core components and LED driver solutions tailored to diverse application scenarios, meeting the customization needs of OEM customers. Specific recommendations are as follows:

TRIAC Core Components

|

Component Model |

Type |

Key Parameters |

Applicable Scenarios |

|

TRIAC-BTA16 |

Bidirectional Thyristor |

Rated Current 16A, Rated Voltage 800V |

High-power lighting (e.g., LED floodlights over 100W, halogen lamps) |

|

BT151S-500R,118 |

RMS Forward Current 12A, Off-State Voltage 400V, Maximum Gate Trigger Current 15mA |

Small-to-medium power lighting (e.g., LED downlights and bedside lamps under 50W) |

|

|

Bidirectional Triggering Diode |

Breakdown voltage range 28-36V, repetitive peak forward current 2A |

Used with thyristors to provide symmetrical trigger signals and reduce flicker |

Triac-compatible LED driver

Customization Services

For volume production customers, Unikeyic offers the following customization services:

- Circuit Design: Develop integrated triac dimmer and LED driver circuits based on client fixture parameters (e.g., power, voltage, dimming range).

- Component Selection: Provide cost-effective component combinations (e.g., thyristor + DIAC + filter capacitor) to reduce customer production costs;

- Testing Support: Provide compatibility test reports to ensure products meet international certification standards like CE and UL;

- Delivery Lead Times: Core components available from stock. Custom driver samples: 7-10 days. Bulk production delivery: 15-20 days.

Recommended Resistor:

How to Build a Sound-Reacting LED Strip that Dances to Music?