What Are Fiber Optic Sensors and How to Choose the Right One?

A fiber-optic sensor is a device that uses the optical properties of optical fibers to detect physical quantities, such as temperature, pressure, and displacement, by measuring changes in light intensity, phase, wavelength, and polarization. It offers strong resistance to interference and high precision.

Selecting the correct model is key to maximizing performance.

First, clearly define the measurement parameters (e.g., temperature/strain) and required accuracy standards. Next, consider the application environment (specialized models are needed for high-temperature or strong electromagnetic scenarios). Match the structural form (integrated/open-frame) and signal interface. Finally, balance performance with budget constraints to ensure perfect alignment with the actual application.

Introduction to Fiber Optic Sensors

Fiber optic sensors are pivotal components in modern sensing technology, underpinning high-precision detection across critical industries from industrial manufacturing to infrastructure monitoring.

What is a Fiber Optic Sensor?

Simply put, a fiber-optic sensor, a core component of an optical detection system, transmits and detects signals via optical fibers. Unlike traditional electrical sensors (e.g., proximity switches or pressure sensors), it operates not by electrical signals but by detecting changes in light—such as intensity, wavelength, or polarization direction—to measure an object's position, distance, temperature, or even deformation.

What is a fiber optic sensor used for? Their applications are extensive, ranging from verifying part positioning in factories with industrial fiber optic sensors to monitoring structural deformation on bridges, and even measuring temperatures within oil wells.

Why use fiber optics in sensing?

The inherent advantages of optical fibers make them an excellent choice for sensing applications.

Key advantages include:

|

|

|

|

| High resistance to interference | Tolerance to extreme environments | Long-distance detection capability | Excellent stability |

| fiber optic sensors are unaffected by electromagnetic noise, ensuring accurate signal transmission. | They can operate reliably under high temperatures or corrosive conditions. | Optical fibers allow signal transmission over kilometers without significant loss. | Their performance remains consistent even in strong electric or magnetic fields. |

How Do Fiber Optic Sensors Work?

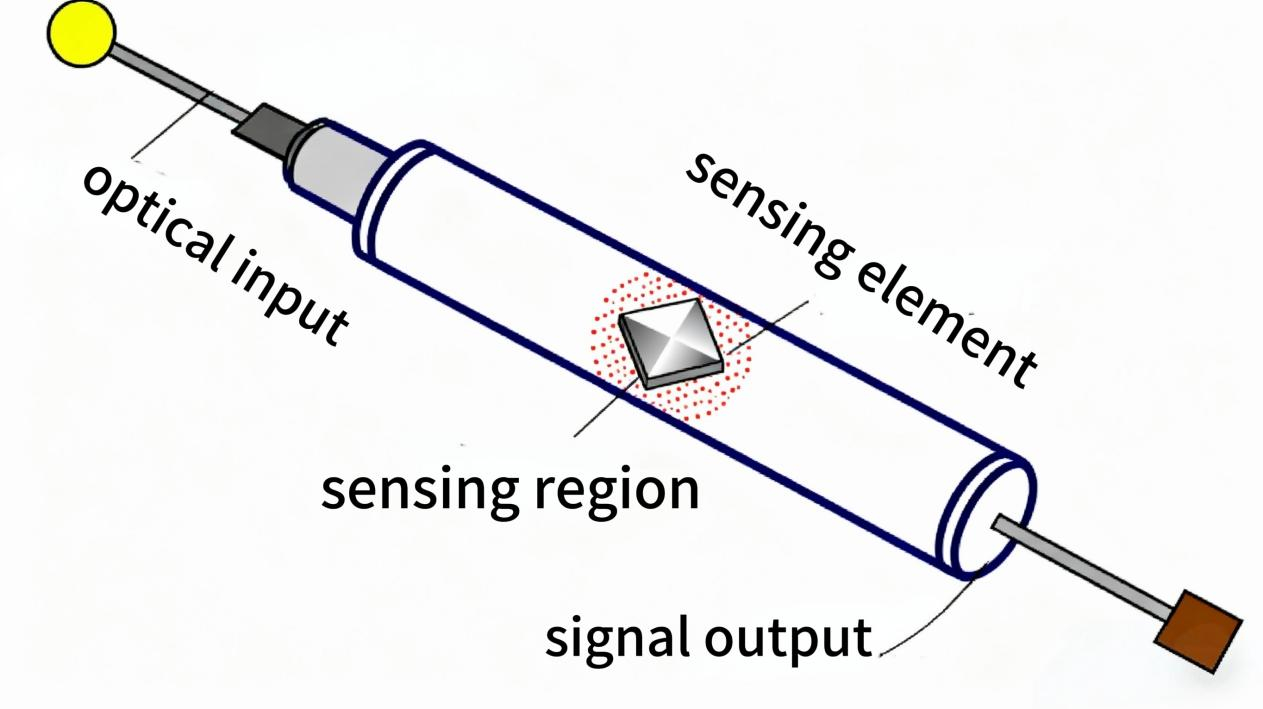

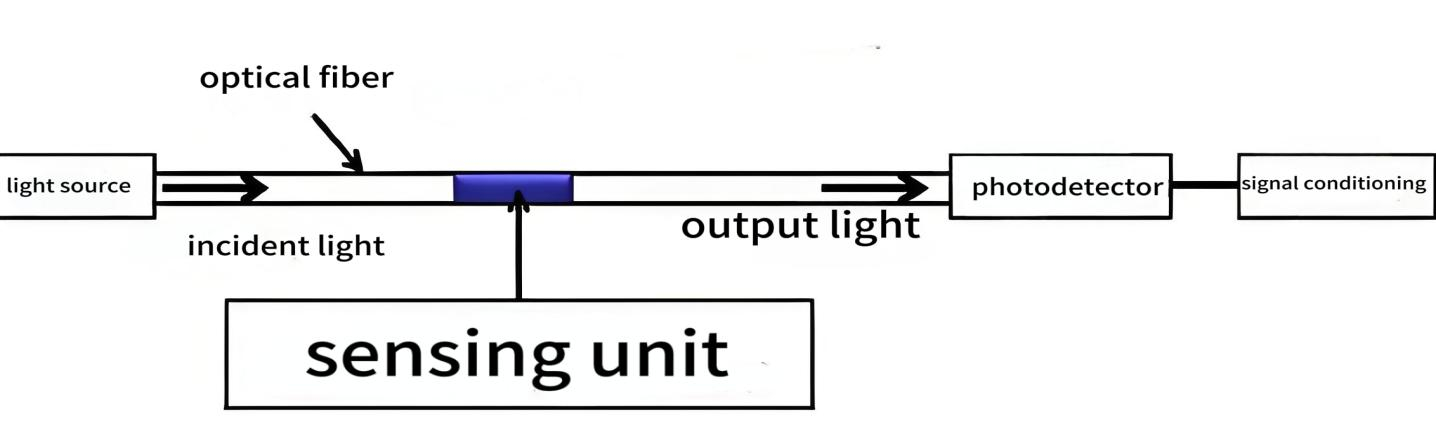

Principle of optical fiber sensor

The core principle of fiber-optic sensors is to send light from the transmitter into the fiber. As light propagates through the fiber, it encounters the target object, leading to changes in intensity, phase, or polarization. The receiver detects these changes to determine the target object's state.

Components and structure

Table: Key components of a fiber optic sensing system

| Module Name | Core Components | Primary Function |

| Light Source | LED, LD | Generates the initial light signal for detection |

| Optical Sensing Section |

Sensing Fiber/Probe |

Detects the measured physical quantity and modulates the characteristics of the light wave |

| Photodetector | PD, APD | Receives modulated optical signals and converts them into electrical signals |

| Signal Processing System | Amplifier, filter, microprocessor, demodulator | Process and analyze electrical signals, extract measured information, and output results |

How do fiber optic strain sensors work?

Fiber optic strain sensors (such as those utilizing FBG technology) can precisely detect "deformation." The principle is as follows: A section of special grating is embedded within the optical fiber. When the fiber is stretched or compressed, the spacing between the grating elements changes, shifting the wavelength of the reflected light. The receiving end detects this wavelength change and calculates the strain of the fiber, thereby determining the deformation (strain) of the measured object.

Types of Fiber Optic Sensors

fiber optic sensors can be categorized in several ways depending on their operating principles and configurations.

By the sensing principle

Intensity-based sensors:

Operate by detecting changes in light intensity (e.g., detecting whether an object blocks light). For example, when a light beam is obstructed by an object, the detected intensity decreases, indicating the object's presence.

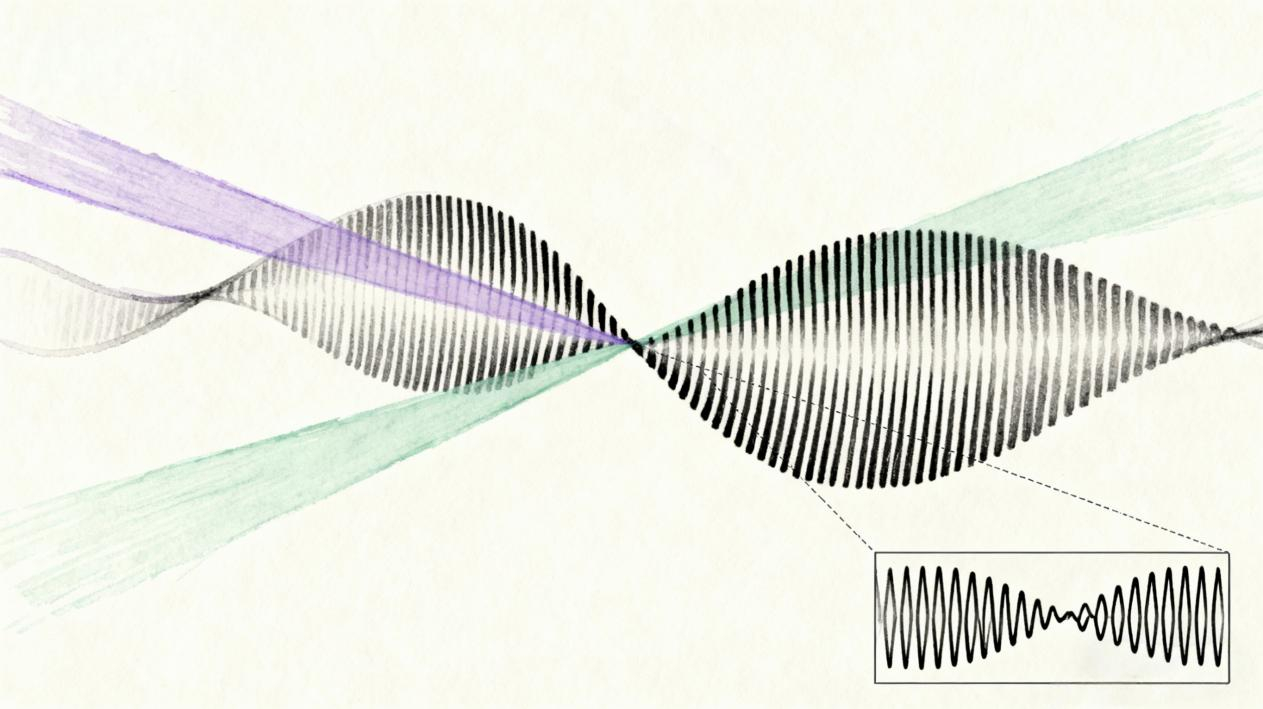

Interferometric sensors:

Utilize the "interference phenomenon of light" (brightness changes when two light beams overlap), offering extremely high precision for detecting minute displacements and vibrations.

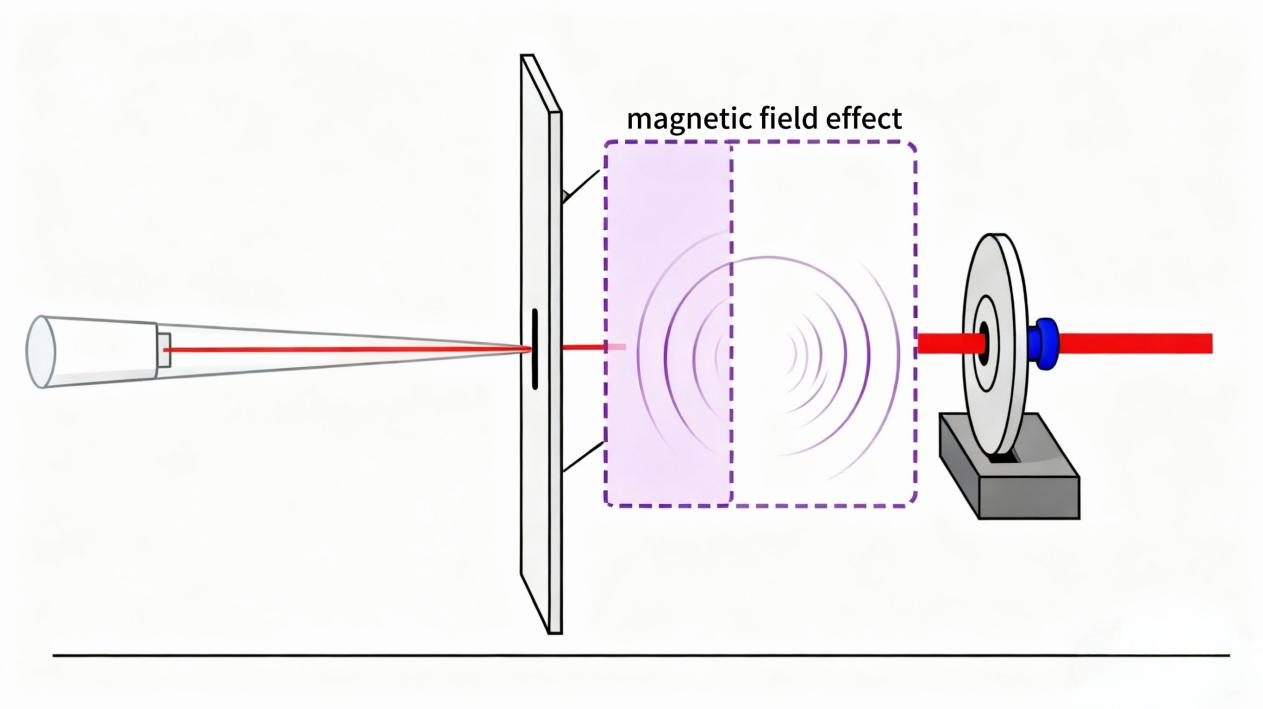

Polarimetric sensors:

Detect changes in the "polarization direction of light," suitable for measuring physical quantities like magnetic fields and currents that affect light polarization.

By configuration

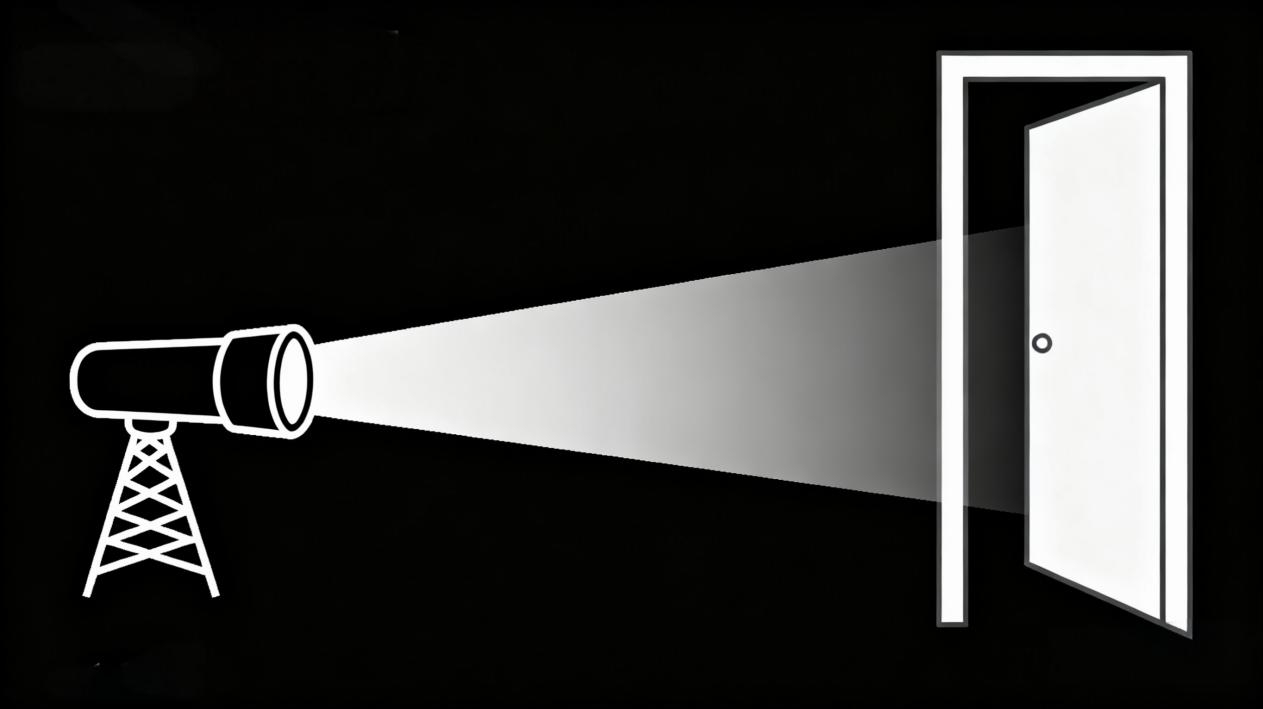

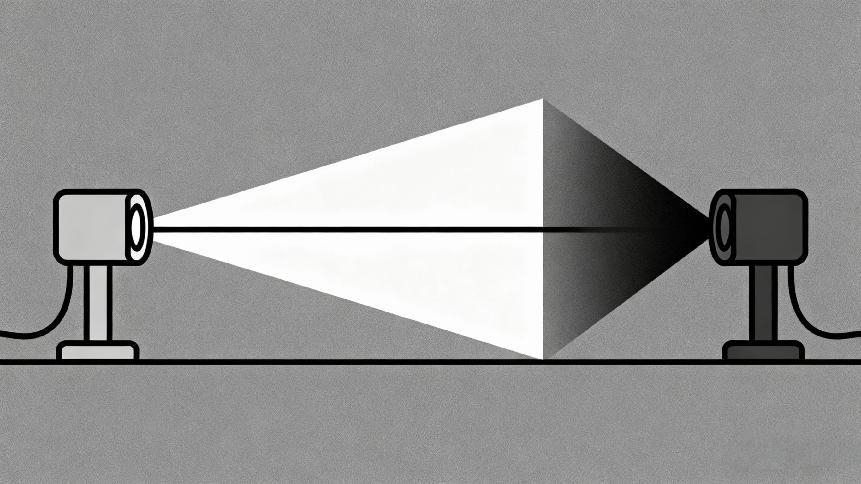

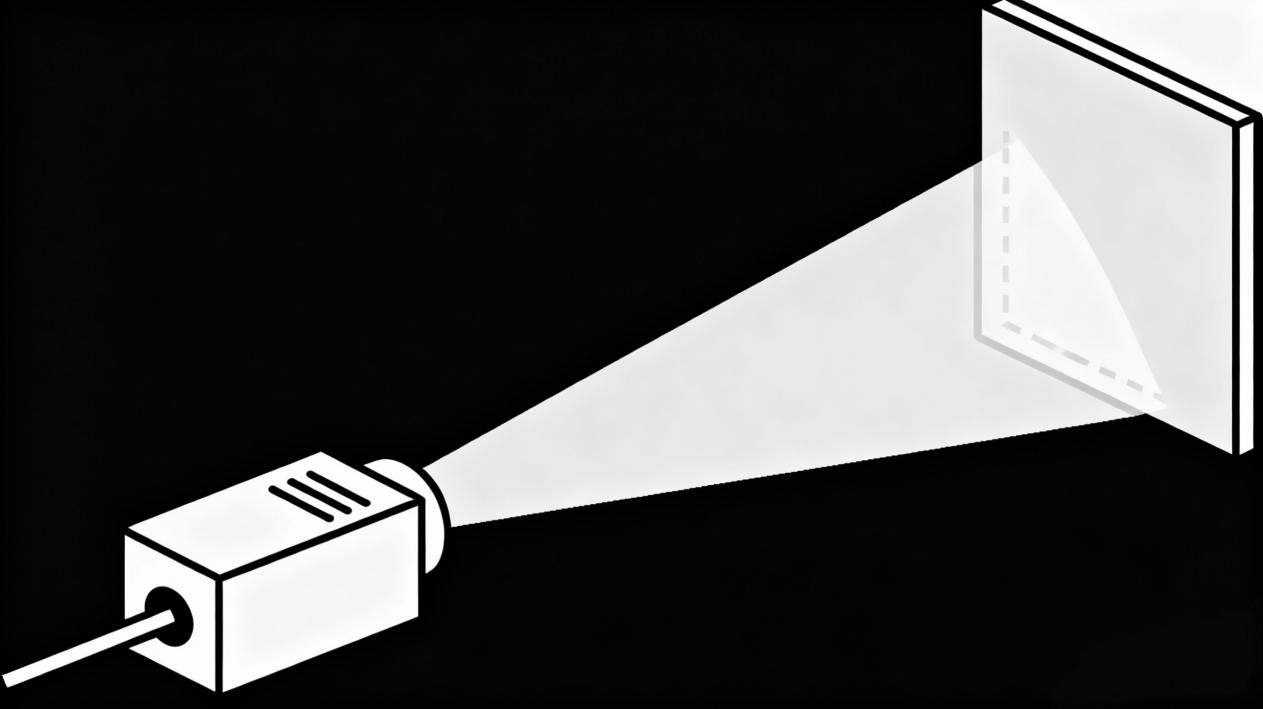

Through-beam:

The transmitter and receiver are separate, with light traveling directly from transmitter to receiver. If an object obstructs the path, the receiver loses light, enabling object detection.

Reflective:

The transmitter and receiver are integrated. Light is emitted toward the target object and reflected to the receiver—suitable for detecting nearby, highly reflective objects.

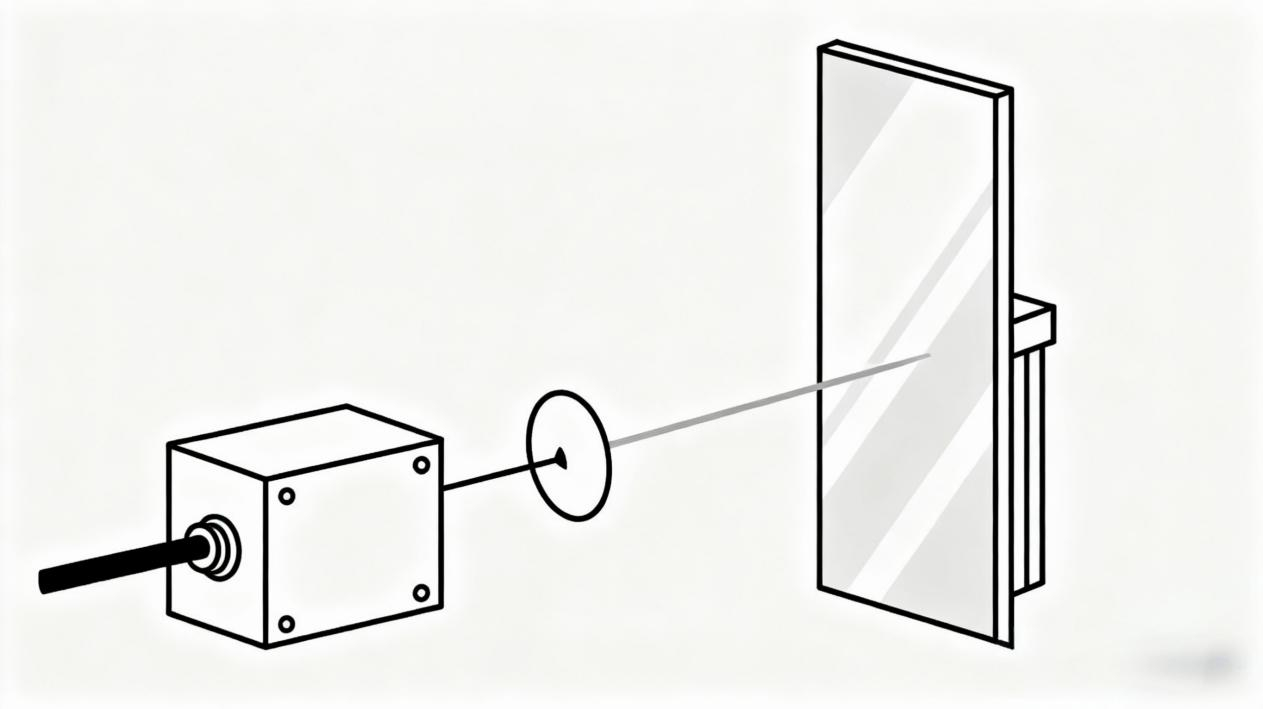

Retro-reflective:

The transmitter, receiver, and a "reflector" work together. Light is reflected to the receiver after hitting the reflector. If an object blocks the path, the light cannot return, enabling object detection.

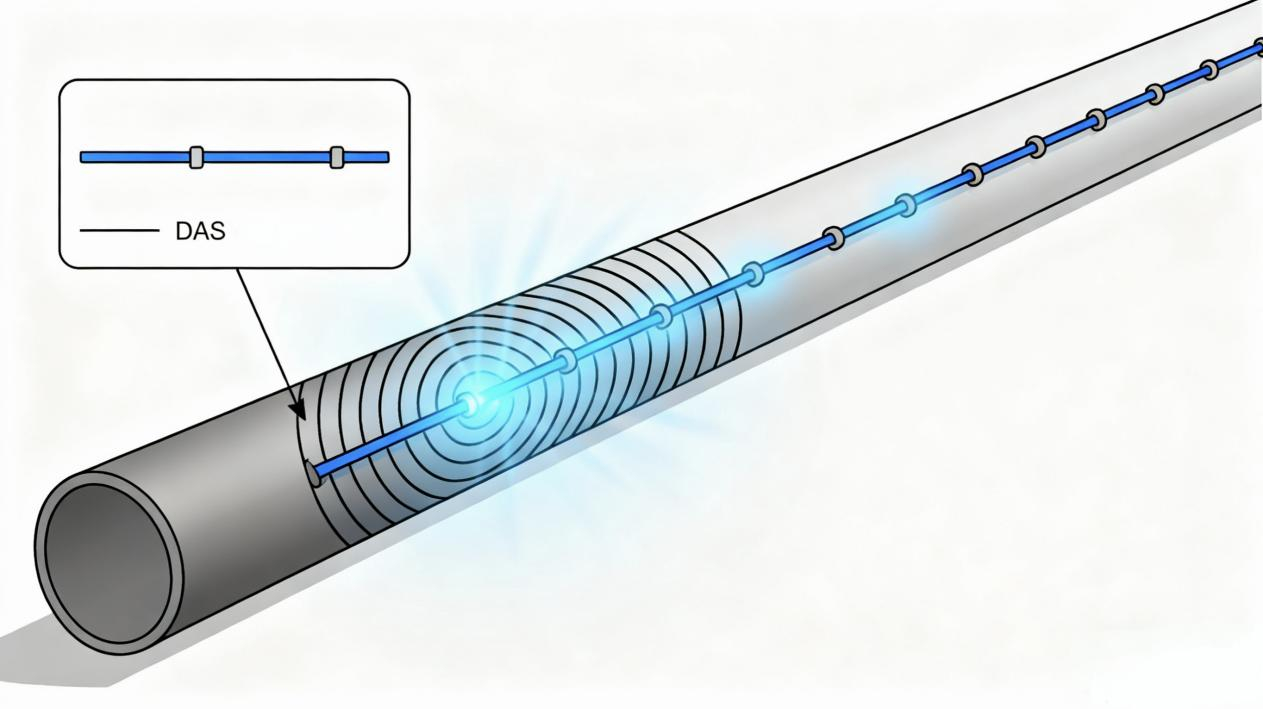

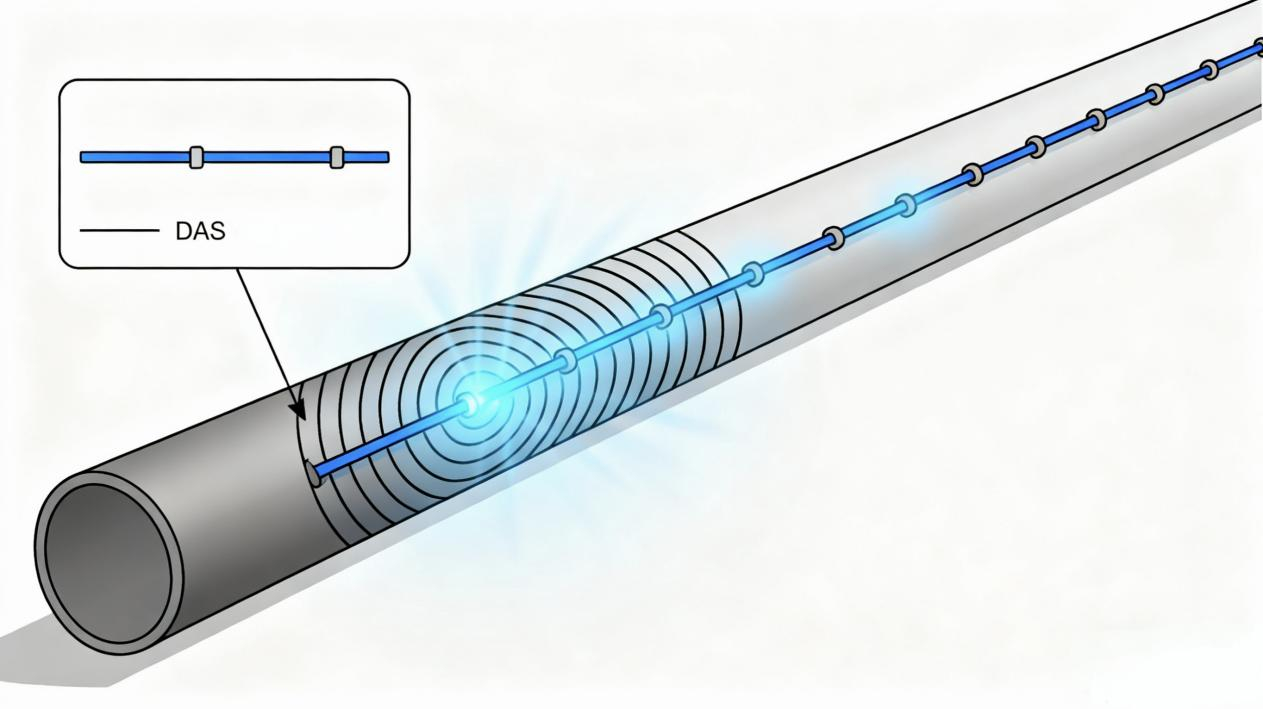

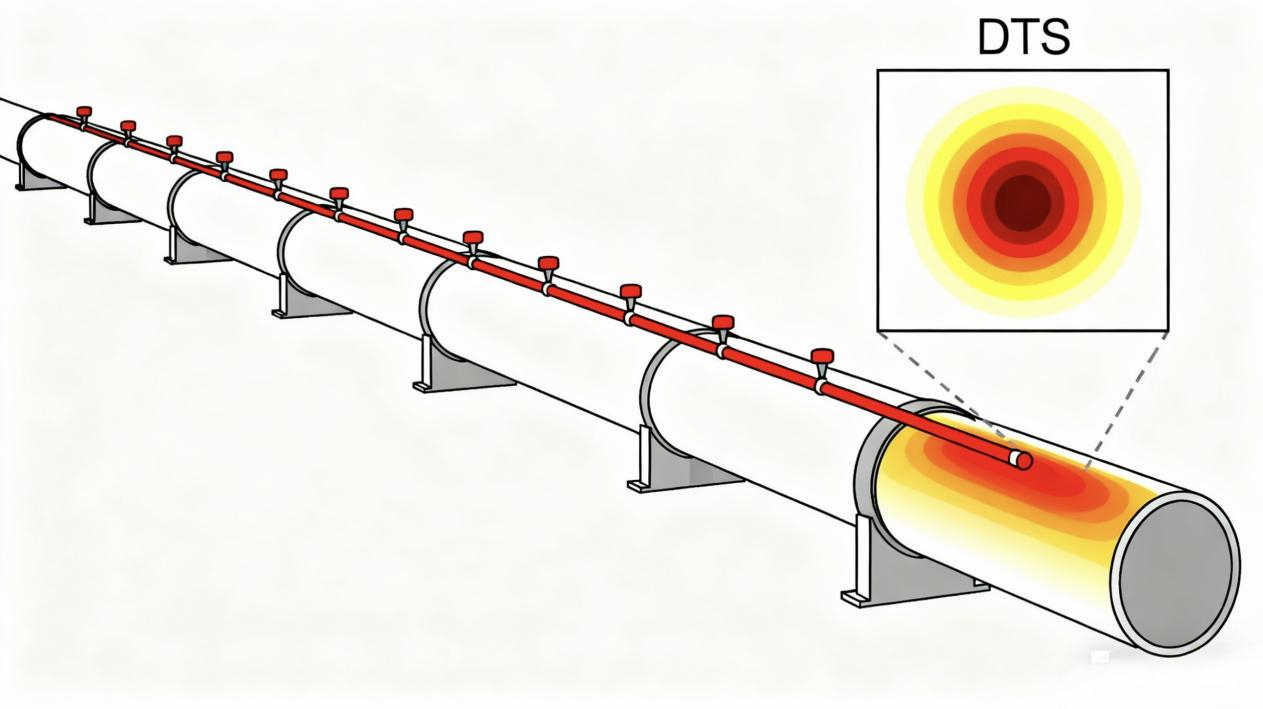

Distributed Sensing Systems (DAS, DTS, DSS):

These methods are commonly used in long-distance infrastructure monitoring.A single fiber optic cable can simultaneously monitor multiple points over long distances, such as detecting vibrations (DAS) or temperature (DTS) in oil pipelines.

By application environment

Special Environment Types:

Models resistant to high temperatures, chemical corrosion, and explosion-proof (e.g., for gas stations and chemical plants).

Flexible vs rigid fiber units:

Flexible fibers (bendable, suitable for detecting complex shapes) and rigid fibers (more robust, suitable for long-term monitoring at fixed locations).

Applications of Fiber Optic Sensors

Fiber optic sensors have permeated various industries. Below are typical application scenarios.

Using fiber Optic Sensors in Industrial Automation

In automated factory production lines, fiber optic sensors perform multiple tasks:

• Detect product presence/absence (e.g., missing part detection on assembly lines);

• Identifying product colors (e.g., sorting parts by color);

• Measuring liquid levels (e.g., water tank level detection);

• Aligning machine edges (e.g., precise material alignment for cutting equipment).

unikeyic offers relevant models from brands including Omron, Keyence, Banner, and Autonics. Contact us for inventory and alternative solutions.

Using fiber Optic Sensors in Infrastructure Monitoring

Large-scale projects like bridges, pipelines, railways, and tunnels rely on fiber optic sensors:

• Monitoring bridge vibrations and deformations (preventing cracks and collapses);

• Detect leaks and corrosion in pipelines (e.g., natural gas pipelines);

• Tracking rail displacement and tunnel wall cracking.

Unikeyic offers relevant models from brands including Omron, Keyence, Banner, and Autonics. Contact us for inventory and alternative solutions.

Using fiber Optic Sensors in Energy and Utilities

In the energy sector, fiber optic sensors ensure safety and efficiency:

• Monitoring temperature and vibration in oil and gas pipelines (preventing leaks and explosions);

• Detect temperatures in wind turbine blades and gearboxes (preventing overheating damage);

• Monitoring substation equipment temperatures (e.g., high-voltage connectors, where high temperatures can cause failures).

Unikeyic offers relevant models from brands including Omron, Keyence, Banner, and Autonics. Contact us for inventory and alternative solutions.

Using fiber Optic Sensors in Smart Manufacturing and Robotics

In the fields of precision manufacturing and robotics:

• Inspecting minute components (such as semiconductor chips, which standard sensors struggle to detect);

• Precisely locating chip positions on automated production lines to ensure processing accuracy.

Unikeyic offers relevant models from brands including Omron, Keyence, Banner, and Autonics. Contact us for inventory and alternative solutions.

Selecting the Right Fiber Optic Sensor

Choosing the right sensor depends on multiple performance and environmental factors.Feeling lost when selecting fiber optic sensors? Focus on these key points.

Selection criteria

When selecting, primarily consider the following:

• Detection Range: How far the sensor can "detect" objects—ranges that are too long or too short are unsuitable.

• Response time: The speed from "object detection" to "signal output"; faster models are needed for high-speed production lines.

• Environmental resistance: Temperature, corrosiveness, explosion-proof requirements, and other factors in the application environment determine whether the sensor can "operate reliably."

• Installation Space: The size of the mounting location; compact sensors are required for confined spaces.

Brand and Model Comparison

| Brand | Key Features | Example Model |

| Omron | High cost-performance ratio, suitable for general industrial applications; extensive model range, convenient procurement. | E32-DC200 |

| Keyence | Exceptionally high precision with leading-edge technology; higher price point, suitable for semiconductor and high-end electronics applications requiring stringent accuracy. | EZ-12M |

| Panasonic | Outstanding stability and durability are widely used in industries such as automotive manufacturing. | FX-501P |

| IFM | Excellent corrosion resistance, frequently used in chemical, petroleum, and other process industries. | OBF500 |

Availability and support from Unikeyic

If unsure about selection, leverage Unikeyic's strengths:

- Global Brand Coverage: Comprehensive selection of brands, including Omron, Keyence, Banner, Autonics, etc., enabling comparison of advantages and disadvantages across different brands.

- Real-Time Inventory: No lengthy waits—rapid delivery when stock is available.

- Technical Support: Our experts will recommend the most suitable model based on your requirements and guide installation and debugging.

Explore our fiber optic sensor selection for more models and specifications.https://www.unikeyic.com/

Future Trends in Fiber Optic Sensing

The development of fiber optic sensors is not static, with these emerging trends for the future:

Miniaturization and AI-driven sensing

Future fiber-optic sensors will become more compact, enabling integration into precision applications such as medical robots and microelectronic devices. Simultaneously, they will deeply integrate with AI—not only "detecting" but also "intelligently analyzing," such as automatically determining whether a signal indicates "normal operation" or "pre-failure signs."

Integration with IoT and predictive maintenance

Fiber optic sensors will integrate more seamlessly with IoT, transmitting detection data to the cloud in real time. This enables "predictive maintenance": anticipating "potential issues" through data changes before equipment failure, allowing for preemptive repairs and reducing downtime losses.

fiber optic sensing technology will continue to evolve toward higher precision and smarter integration, playing a vital role in next-generation industrial systems.