Choosing the Right Terminal Block Connectors: A Complete Guide to Types, Features, and Applications

terminal block connectors are essential components in electrical systems, providing secure and reliable connections between wires in a wide range of applications. Whether in industrial machinery, automotive systems, or consumer electronics, choosing the right terminal block connector ensures optimal performance, safety, and ease of use. In this comprehensive guide, we'll explore the different types of terminal block connectors, their features, and how to choose the right one for your specific needs.

Introduction to Terminal Block Connectors

What are Terminal Block Connectors?

Terminal block connectors are devices used to connect and secure electrical wires in a controlled and organized manner. They provide a safe and reliable method to establish electrical connections, ensuring that wires are firmly held in place without the risk of accidental disconnection or short-circuiting.

Terminal blocks come in various forms and serve different purposes, from simple wire-to-wire connections to complex control systems. These connectors are crucial in industrial, automotive, and consumer electronics, where secure and consistent connections are critical to the proper functioning of electrical systems.

Types of Terminal Block Connectors

There are several types of terminal block connectors, each designed for specific applications and offering unique benefits.

1. Screw-Type Terminal Blocks

Screw-type terminal blocks are the most common and widely used connectors. They work by tightening screws onto the wires, creating a secure, permanent connection. These connectors are known for their reliability and ability to handle high-pressure connections.

Typical Applications:Industrial control panelsPower distribution systemsHigh-current applications

Advantages:Highly secure and reliableSuitable for high-pressure and high-current applications

2. Spring-Cage Terminal Blocks

Spring-cage or spring-clamp connectors use internal springs to secure wires by applying pressure to clamp onto them. These connectors offer the advantage of tool-free installation, faster assembly, and better vibration resistance, making them ideal for dynamic environments.

Typical Applications:Automation systemsControl panelsPanel boards

Advantages:Tool-free installationFaster and more efficient assemblyVibration resistance

3. Push-In Terminal Blocks

Push-in terminal blocks allow for easy wire insertion without the need for tools. The wire is simply pushed into the terminal, and the internal mechanism grips it securely. These connectors are ideal for quick, simple installations and are widely used in low-voltage systems.

Typical Applications:Low-voltage systemsDIY electrical projectsHome automation systems

Advantages:Easy and fast wire insertionSecure connections without tools

4. Feed-Through Terminal Blocks

Feed-through terminal blocks enable direct connections between wires from one terminal to another without internal wiring. These connectors are commonly used in applications that require simple power or signal distribution.

Typical Applications:Power distribution units (PDUs)Signal transfer systems

Advantages:Direct connection between terminalsSimple design for basic applications

5. Multi-Level Terminal Blocks

Multi-level terminal blocks are designed to stack multiple connections in a compact, organized form. These connectors save space in complex electrical systems and allow for more efficient use of panel space.

Typical Applications:Control systemsHigh-density electrical panels

Advantages:Space-saving designSuitable for high-density wiring

6. PCB Mount Terminal Blocks

PCB mount terminal blocks are designed to be mounted directly onto printed circuit boards (PCBs). These connectors are typically used in embedded systems, low-profile designs, and prototypes.

Typical Applications:Embedded systemsPrototyping and circuit boards

Advantages:Low-profile designIdeal for compact and embedded applications

Key Features of Terminal Block Connectors

When selecting terminal block connectors, it's crucial to consider several factors to ensure compatibility with your electrical system and the specific requirements of your application. Below are the key features that play a significant role in choosing the right terminal block for your needs:

Material Considerations

The materials used in terminal block connectors directly affect their performance, durability, and overall effectiveness in electrical systems. Typically, terminal blocks are made from a combination of plastic housings and metal contacts. The choice of material influences insulation, electrical conductivity, and resistance to corrosion. Here's how each material type contributes to the performance of the connector:

Plastic Housings:Insulation: Plastic provides an essential insulating layer that protects the electrical components and prevents short circuits. This insulation ensures safety by isolating conductive parts from external interference.Protection: Plastic housings safeguard the internal components from environmental factors like dust, moisture, and chemicals. This makes them suitable for both indoor and outdoor applications.Durability: While plastic housings are generally durable, their strength and resistance to wear depend on the type of plastic used. Higher-grade plastics such as polyamide (PA) or polycarbonate (PC) are commonly used for enhanced performance in demanding environments.

Metal Contacts:Electrical Conductivity: Metal contacts, usually made from copper, brass, or other alloys, provide excellent electrical conductivity. This ensures that the connection between the terminal block and wires is both reliable and efficient.

Durability: Metal contacts are designed to withstand high temperatures and electrical loads without compromising performance. They maintain consistent contact over time, even under stress.

Corrosion Resistance: For applications exposed to harsh environments, such as marine or outdoor industrial settings, metal contacts are often coated or plated with materials like tin, silver, or gold to prevent corrosion.Why it matters: Choosing the right material for the housing and contacts is essential for ensuring that the terminal block functions well in your specific application, whether it requires insulation, resistance to corrosion, or long-term durability.

Wire Gauge and Compatibility

Wire gauge compatibility is a critical factor when selecting a terminal block connector. Terminal blocks are designed to accommodate different wire gauges, ensuring that the wires are securely connected and do not lead to issues such as loose connections, overheating, or poor electrical conductivity. Here's what you need to consider:

Wire Gauge Range: Terminal blocks are available in a wide range of sizes to handle various wire gauges, from small signal wires (like 28 AWG) to larger power cables (like 10 AWG or even higher). Selecting the correct size ensures a secure fit and optimal conductivity.

Proper Fit: Using a terminal block that fits the wire gauge precisely is essential to avoid issues like:

Loose Connections: Wires that are too thin for the terminal block can slip out, while thicker wires may not make proper contact, leading to electrical resistance or heat generation.

Overheating: Incorrect wire gauge compatibility may cause excessive heat buildup, increasing the risk of failure or fire.

Why it matters: The correct wire gauge compatibility ensures a safe, secure connection that maximizes the efficiency of your electrical system.

Current and Voltage Rating

The current and voltage rating of a terminal block connector specify the maximum electrical load it can safely carry without overheating or failing. These ratings are fundamental in ensuring that your terminal block can handle the power requirements of your application.

Current Rating: Terminal blocks are rated for different current capacities, depending on the wire gauge, contact material, and design. A terminal block with a higher current rating can handle larger power loads, such as in industrial machinery or power distribution systems.

Voltage Rating: Voltage rating is the maximum voltage the terminal block can safely handle. It's important to select a terminal block that matches or exceeds the voltage requirements of your application to prevent electrical arcing or breakdown of insulation.

Why it matters: Choosing a terminal block with a proper current and voltage rating ensures that your connections remain safe and reliable, minimizing the risk of electrical failures or damage to connected equipment.

Safety Features

Safety is paramount when selecting terminal block connectors, especially in high-demand or hazardous environments. Many terminal blocks come with built-in safety features designed to protect both the users and the electrical systems.

Insulation: Insulated terminal blocks prevent electrical shorts and provide safety by isolating live components from the surrounding environment. Insulation materials such as thermoplastic or thermoset plastics help prevent contact with conductive parts, ensuring a safer working environment.

Shock Resistance: Some terminal blocks are designed to resist mechanical shock or vibration, ensuring that the connections remain secure in dynamic environments such as industrial machinery or automotive applications.Compliance with Industry Standards: Many terminal blocks meet international safety and performance standards, such as:

UL (Underwriters Laboratories): Ensures that the terminal block meets rigorous safety standards for electrical systems in North America.

IEC (International Electrotechnical Commission): Certifies compliance with global electrical safety standards.

Flame Retardancy: Certain terminal blocks are made from flame-retardant materials to prevent the spread of fire in case of an electrical fault.

Why it matters: Safety features like insulation, shock resistance, and adherence to international standards ensure that the terminal block performs safely and reliably, especially in environments where electrical hazards are a concern.

The key features of terminal block connectors—material considerations, wire gauge compatibility, current and voltage ratings, and safety features—are all critical to ensuring reliable, efficient, and safe electrical connections in various applications. Understanding these factors helps you choose the most suitable terminal block for your system, ensuring long-term performance and reducing the risk of failures or hazards. Always ensure that the terminal block you choose matches your specific requirements for wire size, power handling, and environmental conditions.

For a wide range of terminal block connectors from top manufacturers, unikeyic Electronics offers a variety of high-quality options. Their selection includes connectors with different materials, ratings, and mounting types, making it easy to find the perfect fit for your needs.

Applications of Terminal Block Connectors

Terminal block connectors are versatile components used across various industries. Here are some key application areas:

Industrial Applications

In industrial environments, terminal blocks are used for machinery, control systems, and automation equipment to ensure safe and reliable wiring. They are often used in control panels, power distribution systems, and automation systems.

Automotive Applications

In the automotive industry, terminal blocks are used in wiring systems to ensure secure connections in environments prone to vibration and temperature fluctuations.

Consumer Electronics

In consumer electronics, terminal blocks can be found in devices such as home appliances, communication devices, and other electrical equipment where secure wiring connections are crucial.

Power Distribution and Control

Terminal blocks are commonly used in power distribution panels and circuit boards, where they provide reliable connections for electrical power distribution and signal transfer.

How to Choose the Right Terminal Block Connector for Your Application

Factors to Consider When Selecting a Terminal Block Connector

When choosing a terminal block connector for your electrical application, several factors need to be considered to ensure proper functionality, safety, and durability. Below is a detailed breakdown of the key factors you should evaluate:1. Wire Size and TypeThe wire size (gauge) and type of wire used in your system play a crucial role in selecting the right terminal block connector. Ensuring compatibility between the wire and the connector ensures a secure connection and optimal performance.

Wire Gauge: Terminal blocks are designed to accommodate a specific range of wire gauges. Ensure that the connector supports the wire gauge used in your application. Too small a terminal block may not securely hold the wire, while a terminal block that’s too large could lead to poor contact or excessive movement.

Wire Type: The type of wire—whether solid, stranded, or flexible—also affects the choice of terminal block. For instance:

Solid wire is rigid and needs a connector that can grip it tightly.

Stranded wire has multiple small wires and requires a connector with a slightly different clamping mechanism to hold the strands together securely.

Flexible wire may require specific connectors designed for flexibility and quick disconnection.

Why it matters: Ensuring that the terminal block is compatible with the wire size and type guarantees that the wire will be properly secured, reducing the risk of electrical faults like poor connections, arcing, or overheating.

2. EnvironmentThe operating environment plays a significant role in the durability and performance of terminal block connectors. Here are the key environmental factors to consider:

Temperature Range: Some terminal blocks are designed to operate within specific temperature ranges. Choosing a connector with the correct thermal resistance ensures the components remain stable and functional under temperature extremes. For high-temperature environments, select terminal blocks made of materials with a high melting point, such as ceramic or specialized plastics.

Exposure to Moisture: If the terminal block will be used in environments with moisture, humidity, or potential exposure to corrosive elements, it’s important to choose connectors with appropriate protection, such as:IP-rated (Ingress Protection) connectors that can prevent water or dust ingress.

Corrosion-resistant materials, like stainless steel or plastic with UV protection, to avoid deterioration in outdoor or harsh environments.

Indoor vs. Outdoor Use: For outdoor or harsh industrial environments, ensure the terminal blocks are rated for such applications, with appropriate sealing, UV resistance, and protection against physical damage. Indoor systems may have fewer environmental challenges but still need to be resistant to factors like heat from nearby equipment.

Why it matters: The right terminal block connector ensures that your electrical system operates safely and efficiently, even in challenging environmental conditions, preventing premature failure due to external factors.

3. Power RequirementsChoosing a terminal block that meets the current and voltage rating requirements of your application is essential to ensure the electrical system operates safely and efficiently. Here’s what to consider:

Current Rating: Every terminal block has a maximum current rating, typically measured in amps (A). Ensure that the connector you choose can handle the amount of current your system requires. Selecting a terminal block with a lower current rating than needed can cause overheating, increased resistance, or even fires.

Voltage Rating: Each terminal block also has a voltage rating, which indicates the maximum voltage it can handle. It’s important to choose a connector that matches or exceeds the voltage needs of your application to prevent electrical arcing or breakdowns in insulation.

Why it matters: Correctly selecting the current and voltage rating ensures that the terminal block connector can safely carry the electrical load, preventing system failures and potential hazards.

4. Mounting TypeTerminal blocks come in a variety of mounting types, and the choice of mounting depends on how the connector will be used in your system. Here are some common options:

Panel Mount: Panel-mounted terminal blocks are designed to be mounted on the surface of a panel. This type is commonly used in control panels or power distribution units (PDUs). They offer easy access for maintenance and connections.

PCB Mount: Printed Circuit Board (PCB) mount terminal blocks are designed to be soldered directly onto a PCB. This type is used in embedded systems, compact designs, and consumer electronics where space is a concern. PCB mount blocks offer a secure and low-profile solution for circuit board applications.

Rail Mount: Some terminal blocks are designed for DIN rail mounting, which is commonly used in industrial control systems. This mounting type offers ease of installation and flexibility for system expansion.

Screwless Mount: Some modern terminal blocks offer screwless or snap-fit mounting, ideal for quicker installations where ease of use is important, such as in low-voltage systems or DIY projects.

Why it matters: Choosing the correct mounting type ensures that the terminal block integrates seamlessly into your system, whether it's a large industrial panel or a small embedded design.

Tips for Proper Connection

Once you've selected the appropriate terminal block connector for your application, it’s important to follow a few best practices to ensure a secure and reliable connection:

1. Proper Wire StrippingBefore inserting the wire into the terminal block, ensure that the wire is stripped to the correct length. This will allow the metal conductor to make proper contact with the terminal block's metal contacts while preventing excessive exposed wire from creating short circuits.

Tip: Use a wire stripper to remove only the insulation, leaving the conductor exposed to make a secure connection. If you strip too much wire, it could cause a short circuit, while insufficient stripping could lead to poor conductivity.

2. Follow Torque Specifications for Screw-Type BlocksFor screw-type terminal blocks, it’s essential to tighten the screws to the recommended torque specifications. Over-tightening can damage the connector, while under-tightening can result in a loose connection, leading to high resistance, overheating, or even complete disconnection.

Tip: Use a torque screwdriver to ensure consistent pressure when tightening the screws. Follow the manufacturer's recommended torque values to ensure a safe and secure connection.

3. Ensure Full Insertion of WireFor the best electrical contact, make sure that the wire is fully inserted into the terminal block. This will ensure the metal contacts make full contact with the wire, reducing resistance and preventing the risk of overheating or connection failure.

Tip: After inserting the wire, give it a gentle tug to ensure it’s properly seated and that the connection is firm.

When selecting a terminal block connector, carefully considering factors like wire size, environmental conditions, power requirements, and mounting type is essential to ensuring a safe and efficient electrical system. Proper connection techniques—such as ensuring proper wire stripping, adhering to torque specifications, and ensuring full insertion—will further enhance the reliability and performance of your connections. By following these best practices, you can optimize your system for long-term, safe operation.

Top Brands and Manufacturers of Terminal Block Connectors

Top Brands and Manufacturers of Terminal Block ConnectorsWhen it comes to terminal block connectors, choosing products from reputable manufacturers is essential to ensure reliability, durability, and safety. Several leading brands are recognized for their high-quality products and commitment to meeting international standards. Here’s a closer look at some of the top manufacturers of terminal block connectors:

1. Phoenix Contact

Overview: Phoenix Contact is a global leader in industrial connectivity solutions and one of the most well-known manufacturers of terminal block connectors. The company is renowned for offering a wide range of high-quality terminal blocks suited for industrial, automation, and control applications.

Figure 1: Phoenix Contact

Key Features:Innovative Technology: Phoenix Contact is known for its innovative designs, such as tool-free installation and modular terminal blocks that can be customized to meet specific application needs.

High Durability: Their terminal blocks are built to withstand harsh industrial environments, offering robust protection against factors like high temperatures, humidity, and mechanical stress.

Comprehensive Product Line: Phoenix Contact provides a diverse selection of terminal blocks, including screw-type, spring-cage, and push-in variants, along with accessories and mounting solutions.

Applications: Phoenix Contact’s terminal blocks are commonly used in:

Industrial automation systemsControl panelsPower distribution systemsSignal transmission applications

Why Phoenix Contact?: Their products are known for outstanding reliability, durability, and ease of use, making them an ideal choice for high-demand industries like automotive, energy, and manufacturing.

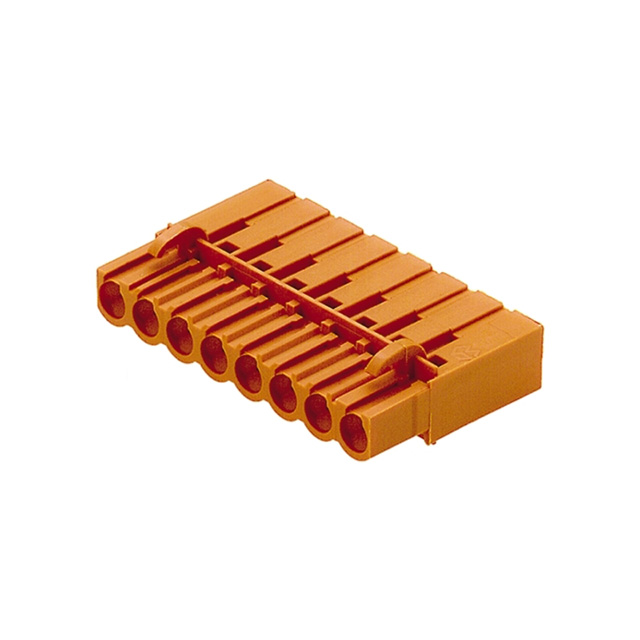

2. WAGO

Overview: WAGO is another industry leader that specializes in connection and automation technology. With over 60 years of experience, WAGO has earned a reputation for producing top-quality terminal blocks that offer advanced technology and ease of use, especially in applications requiring flexibility and fast assembly.

Figure 2: WAGO

Key Features:Spring-Pressure Connection: WAGO is renowned for its spring-cage technology, which allows for tool-free, vibration-resistant, and secure connections. Their terminal blocks are designed for quick and easy wire insertion without the need for screws, reducing installation time.

Versatility: WAGO’s terminal blocks come in various designs, including compact, modular, and multi-level configurations, allowing for flexibility in system design and optimization of space.

International Certifications: WAGO terminal blocks comply with global standards such as UL, IEC, and ATEX, ensuring that they meet rigorous safety and quality requirements.

Applications: WAGO’s terminal blocks are used extensively in:Industrial control panelsAutomation systemsPower distribution networksMachine wiring

Why WAGO?: WAGO’s spring-cage technology provides ease of use and excellent vibration resistance, making them ideal for both high-volume and mission-critical applications. Their products are also highly versatile and suitable for various environments.

3. TE CONNECTIVITY

Overview: TE Connectivity is a global technology company known for providing a broad range of connectivity solutions, including terminal block connectors. With a focus on performance and innovation, TE Connectivity offers products designed for the most demanding applications across multiple industries.

Figure 3: TE Connectivity

Key Features:High-Quality Materials: TE Connectivity terminal blocks are made from premium materials such as high-performance plastics and durable metals, ensuring high conductivity, corrosion resistance, and long-term reliability.

Wide Range of Configurations: TE Connectivity offers an extensive selection of terminal blocks, including options for panel-mount, PCB-mount, and wire-to-wire connections.

Customizable Solutions: They provide customizable terminal block solutions to fit specific voltage, current, and size requirements, allowing for flexibility in product design.

Applications: TE Connectivity’s terminal blocks are used in various sectors, including:TelecommunicationsIndustrial automationTransportation (automotive, rail)

Why TE Connectivity?: Known for its cutting-edge technology, TE Connectivity offers a wide range of reliable and customizable terminal blocks, making them a great choice for industries where performance and flexibility are critical.

4. Weidmüller

Overview: Weidmüller is a renowned German manufacturer specializing in industrial connectivity solutions, including terminal block connectors. They are known for their high-quality, precise, and reliable products designed to meet the evolving demands of industrial automation, energy, and power distribution.

Figure 4: Weidmüller

Key Features:Modular and Compact Designs: Weidmüller offers modular terminal blocks, which can be tailored for specific configurations and applications, helping optimize space in control panels.

Advanced Connection Technology: Weidmüller incorporates advanced features such as spring-cage technology and push-in connections for tool-free assembly and increased vibration resistance.

Wide Product Range: The company offers a diverse range of terminal blocks including multi-level, feed-through, and PCB mount terminal blocks. They also provide comprehensive solutions for signal, power, and control applications.

Applications: Weidmüller terminal blocks are commonly used in:Industrial automation systemsMachine building and roboticsRenewable energy applicationsControl and monitoring equipment

Why Weidmüller?: Weidmüller is known for its focus on innovation and engineering excellence. Their terminal blocks are reliable, easy to use, and optimized for industrial and automation systems, making them ideal for complex electrical installations.

Why Choose These Brands?

These four manufacturers—Phoenix Contact, WAGO, TE Connectivity, and Weidmüller—are among the best in the industry for several reasons:

Reputation for Quality: All of these brands are known for their high-quality manufacturing standards, ensuring reliability and durability.

Compliance with International Standards: These brands adhere to the highest safety and quality standards, including certifications such as UL, IEC, and CE, ensuring their products are safe for use in global markets.

Variety of Options: Whether you need screw-type, spring-cage, push-in, or PCB-mount terminal blocks, these manufacturers offer a wide range of options to suit any application.

Innovative Features: With advancements like tool-free installation, vibration resistance, and compact designs, these brands are leaders in providing easy-to-use, high-performance products for complex systems.

Unikeyic Electronics: Your Trusted Distributor for Terminal Block Connectors

Unikeyic Electronics is an authorized distributor offering a variety of Terminal Block Connectors from trusted brands like Phoenix Contact, WAGO, TE Connectivity, and Weidmüller. By partnering with these leading manufacturers, Unikeyic Electronics ensures that you have access to the highest-quality connectors for all your electrical and industrial needs.

Whether you’re working on an industrial automation project, power distribution system, or consumer electronics, Unikeyic Electronics can provide you with the right terminal block connectors to ensure safe, reliable, and efficient electrical connections. Their comprehensive product range, combined with expert customer support, makes Unikeyic Electronics your go-to distributor for all your terminal block connector needs.

Contact Unikeyic Electronics today for more information or to place your order for high-quality terminal block connectors!

Conclusion

Choosing the right terminal block connector is critical to ensuring reliable, safe, and efficient electrical connections. By considering factors such as wire size, power requirements, and environmental conditions, you can select the most appropriate connector for your application. If you’re looking for a wide variety of terminal block connectors, Unikeyic Electronics offers a broad range of options from leading manufacturers, ensuring you find the perfect connector for your needs.

Explore their offerings today and consult with experts to choose the ideal terminal block connectors for your next project.