Measure Light Intensity Photoresistor Arduino

In a home automation project, an Arduino Uno is used to control indoor lighting according to the surrounding light levels. A light sensor measures light intensity, transmitting data to the Arduino. In low light conditions, the sensor's resistance rises, prompting the Arduino to turn on an LED light, creating a cozy atmosphere for reading or working. On the other hand, as light levels rise, the photoresistor's resistance drops, prompting the Arduino to switch off the LED. Now let's explore Measuring Light Intensity Photoresistor Arduino!

Understanding Photoresistors

Composition and Structure

A photoresistor, often referred to as a light-dependent resistor (LDR) or photo-conductive cell, is a passive device that reduces its resistance when exposed to higher levels of light on its sensitive area; it demonstrates photoconductivity. A photoresistor serves in circuits that detect light and in switching circuits activated by light or darkness, functioning as a semiconductor resistance. In darkness, a photoresistor's resistance can reach several megaohms (MΩ), whereas in light, it may drop to several hundred ohms. When the incident light on a photoresistor surpasses a specific frequency, the photons absorbed by the semiconductor provide bound electrons with sufficient energy to move into the conduction band. The resulting free electrons (along with their hole counterparts) facilitate electrical conduction, thus reducing resistance. The resistance range and sensitivity of a photoresistor can vary significantly between different devices. Additionally, distinct photoresistors can respond notably differently to photons across specific wavelength ranges.

A photoelectric device may be classified as either intrinsic or extrinsic. An intrinsic semiconductor possesses its own charge carriers and is not as efficient as a semiconductor like silicon. In intrinsic devices, the majority of electrons reside in the valence band, so the photon needs sufficient energy to elevate the electron across the full bandgap. Extrinsic devices contain added impurities known as dopants, which possess ground state energy that is nearer to the conduction band; as a result, electrons require less energy to jump, so lower energy photons (meaning longer wavelengths and lower frequencies) can effectively activate the device. When a sample of silicon has certain atoms substituted with phosphorus atoms (impurities), it will have additional electrons available for conduction.

The basic structure and formation of a photoresistor consist of a light-sensitive semiconductor material, typically composed of cadmium sulfide. Without light, an LDR has extremely high resistance of approximately several megaohms. Nevertheless, when mild conditions are present, it shows low resistance characteristics, possessing a resistance of around a few hundred ohms.

The gadget features a serpentine or zigzag pattern that is composed of cadmium sulfide. This serpentine configuration is executed to achieve the desired energy rating and resistance. This melody distinguishes a pair of metal connections. The entire structure is housed in a plastic case, which allows for direct exposure to the incident radiation. Since it is essential to vary the resistance through the influence of light in an LDR, the resistance of the metal contacts needs to be minimal.

The picture of a photoresistor is shown below:

SparkFun Electronics SEN-09088, you can see more here

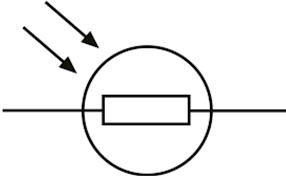

Photoresistor Symbol

To depict a Photoresistor in a circuit diagram, the symbol selected was one that signifies it as a light-sensitive component, as well as acknowledging its role as a resistor.

Working Principle of a Photoresistor

The operational principle of a photoresistor, commonly known as a light-dependent resistor (LDR) or photocell, relies on its ability to change resistance in response to different light levels, as it lacks a P-N junction diode and is constructed from high-resistance semiconductor material. A photoresistor generally consists of a semiconductor material, commonly made from cadmium sulfide (CdS) or cadmium selenide (CdSe), encased in a protective shell. The semiconductor material is light-sensitive, meaning its electrical properties are activated through exposure to light. When there is no mild or when subjected to low mild levels, the semiconductor material has a reduced number of photons (mild particles) engaging with it. Consequently, the material holds additional electrons in its atoms, restricting their movement and establishing a more resistant pathway for electric current. When bright light hits the photoresistor, the semiconductor material takes in photons, supplying energy to the electrons. This energy allows electrons to move more freely, decreasing the material's resistance. Consequently, there is reduced impedance to the flow of electric current through the photoresistor.

The exchange occurring in the movement of electrons in the semiconductor material leads to a changeable resistance in the photoresistor. Resistance is elevated in dark conditions or low mild situations and decreases as the mild intensity rises. Photoresistors are incorporated into electrical circuits to take advantage of their changing resistance. For instance, in a voltage divider setup, the photoresistor is connected in series with a fixed resistor. The voltage across the photoresistor changes as its resistance fluctuates with light levels. The different resistances of the photoresistor lead to a related change in the voltage drop across it. This voltage variation can be used to initiate specific reactions in digital systems or apparatus connected to the photoresistor. The variable resistance of photoresistors reveals uses in camera exposure management, automatic lighting systems, security systems, and various other devices that require a reaction to fluctuating light levels.

Classification of Photoresistors

1. Intrinsic Photoresistors

Intrinsic photoresistors are created using natural semiconductor materials such as silicon or germanium. These semiconductors possess their unique charge carriers. Their conduction band does not contain any free electrons. They include holes within the valence band. To stimulate electrons present in an intrinsic semiconductor, from the valence band to the conduction band, adequate energy must be provided to overcome the entire bandgap.

They are primarily constructed from intrinsic semiconductor materials, necessitating high energy photons to activate the device, making them suitable for detecting light at high frequencies.

2. Extrinsic Photoresistors

Extrinsic photoresistors are composed of semiconductor material infused with dopants. The power of the ground state in their electrons is nearer to the conduction band. As the electrons no longer have to jump as far, lower energy photons (meaning longer wavelengths and lower frequencies) are sufficient to activate the device.

As only a small amount of energy is needed to activate the device, they are intended to be used with longer wavelengths and lower frequency light. Extrinsic photoresistors sense infrared rays, while intrinsic photoresistors typically respond to light waves of a higher frequency.

Characteristics of Photoresistors

1. Spectral Response: The spectral response is essential for grasping the photoresistor's sensitivity to specific wavelengths of light. This specification allows the device to adapt to the particular light source or surrounding light conditions in the application.

2. Dark Resistance (Rd) and Illuminance Resistance (Ri): These figures represent the resistance of the photoresistor in dark and lit conditions, respectively. They are essential in establishing the baseline resistance and the lowest resistance feasible under bright light, providing a basis for circuit design.

3. Tolerance: Tolerance indicates the permissible variation from the designated resistance value. In applications where precise control or measurement of light is crucial, a minimal tolerance guarantees that the photoresistor delivers accurate and dependable results.

4. Countermeasures: The range of resistance is crucial as it determines the operating mode of the photoresistor. It assesses how responsive the device is to various light sources and guarantees that it can produce the necessary outcomes in diverse lighting situations.

5. Light Sensitivity: Photoresistors are highly responsive to illumination. Their resistance diminishes as the depth of mild increases and the opposite is true. These assets render them advantageous in different packages where light levels must be detected or measured.

6. Resistance Range: Photoresistors typically exhibit a broad range of resistance values. In dim or low light conditions, their resistance is high, often in the megaohm range. As light intensity rises, the resistance diminishes, sometimes falling to 300 ohms or even lower in bright light.

7. Response Time: The response time of a photoresistor indicates how swiftly it can respond to changes in light intensity. Photoresistors generally exhibit a slower reaction time in comparison to other light sensors, such as photodiodes. The reaction time is a crucial focus in programs where rapid changes in light must be correctly recognized.

8. Nonlinear Response: The connection between a photoresistor's resistance and the intensity of incoming light is nonlinear. The trade in resistance is not equal to the exchange in light depth. As a result, calibration may be necessary in specific programs to achieve accurate light readings.

Connecting a Photoresistor to an Arduino

Required Hardware Components

Arduino module (e.g., Arduino Uno, Arduino Nano)

Photoresistor sensor module (find the photoresistor here)

10K ohm resistor (for voltage divider setup)

Prototype board and jumper cables

Arduino USB cable

PC with the Arduino IDE (you can find at https://www.arduino.cc/en/software)

Code Overview

The code needed is shown in the figure below:

const int photoresistorPin = A0; // Analog pin connected to the Photoresistor Sensor module

void setup0 {

Serial.begin(9600); // Initialize serial communication for debugging (optional)

}

void loop0 {

int lightValue = analogRead(photoresistorPin): // Read the analog value from the Photoresistor

// Display the light value on the Serial Monitor

Serial.print("Light Intensity: ");

Serial.printIn(lightValue);

// Adjust the threshold value according to your environmentint

int threshold = 500;

if (lightValue < threshold){

// Low light detected! Add your desired action here.

// For example, turn on a light, display a message, or trigger other events.

}

delay(100); // Add a small delay to avoid rapid repeated detections

}

Open the Arduino IDE enter the code shown above.

Step-by-Step Connection Guide

Step 1: Electrical Connections

Attach the Photoresistor Sensor module to the Arduino board in the following manner:

Attach one leg of the Photoresistor to the 5V pin on the Arduino.

Link the remaining leg of the Photoresistor to the A0 analog input pin on the Arduino.

Connect a 10K ohm resistor between the A0 pin and the GND pin of the Arduino.

Step 2: Coding

Step 3: Uploading the program

Link your Arduino board to your computer via the USB cable and choose the correct board and port in the Arduino IDE. Next, press the “Upload” button to transfer the code to the Arduino.

Step 4: Monitoring the Light Intensity

After the code is uploaded successfully, launch the Serial Monitor from the Arduino IDE (Ctrl + Shift + M). The Serial Monitor will show the analog values, indicating the light intensity sensed by the Photoresistor Sensor module. Shield the photoresistor with your hand or subject it to different lighting conditions to see variations in the light intensity readings.

Step 5: Try Out and Engage

With the Photoresistor Sensor module now configured and reactive to light, you can try out various threshold values to modify its light sensitivity. Utilize the light intensity measurements to manage different elements of your project, including activating lights in dim surroundings or responding to fluctuating lighting circumstances.

Programming the Arduino for Light Measurement

Sample Code for Beginners

The code is shown below:

const double k = 5.0/1024;

const double luxFactor = 500000;

const double R2 = 10000;

const double LowLightLimit = 200;

const double B = 1.3*pow(10.0,7);

const double m = -1.4;

const int LED = 7;

double light_intensity (int RawADC0) {

double V2 = k*RawADC0;

double R1 = (5.0/V2 - 1)*R2;

double lux = B*pow(R1,m);

return lux;}

void setup() {

Serial.begin(9600);

pinMode(LED, OUTPUT);

}

void loop() {

double intensity = light_intensity(analogRead(0));

if (intensity < LowLightLimit) {

digitalWrite(LED, HIGH);

} else {

digitalWrite(LED, LOW);

}

Serial.println(intensity);

delay(1000);

}

Explanation of Code Functionality

Constants and Variables:

const double k = 5.0 / 1024;kconverts the ADC reading to a voltage value in the range of 0–5V.const double luxFactor = 500000;light_intensity.const double R2 = 10000;const double LowLightLimit = 200;const double B = 1.3 * pow(10.0, 7);const double m = -1.4;mis an exponent that helps determine the relationship between the resistance (R1) and the light intensity. The value-1.4suggests a logarithmic or power-law relationship.-

const int LED = 7;

Pin 7 is defined for the LED. The LED will be controlled based on the light intensity.

light_intensity Function:

This function calculates the light intensity in lux using the raw ADC reading:

cpp

double light_intensity (int RawADC0) {

double V2 = k * RawADC0; // Convert raw ADC value to voltage (0-5V)

double R1 = (5.0 / V2 - 1) * R2; // Calculate the resistance R1 using the voltage divider formula

double lux = B * pow(R1, m); // Calculate the light intensity (lux) using the formula

return lux; // Return the light intensity value

}

V2 = k * RawADC0;:The raw ADC value (RawADC0, typically between 0-1023) is converted to voltage (0–5V).R1 = (5.0 / V2 - 1) * R2;:The code calculates the resistance of the light-dependent resistor (LDR) in the circuit (R1). The formula is derived from the voltage divider rule.lux = B * pow(R1, m);:Using the resistance (R1) and constantsBandm, the light intensity in lux is calculated. Thepow(R1, m)part represents a power-law relationship between the resistance and the light intensity.

setup Function:

cpp

void setup() {

Serial.begin(9600); // Start serial communication at 9600 baud rate

pinMode(LED, OUTPUT); // Set the LED pin as an output pin

}

- Initializes serial communication for debugging or monitoring via the Serial Monitor.

- Configures pin 7 (LED pin) as an output pin.

loop Function:

cpp

void loop() {

double intensity = light_intensity(analogRead(0)); // Read raw value from analog pin 0 and calculate light intensity

if (intensity < LowLightLimit) { // If light intensity is below threshold

digitalWrite(LED, HIGH); // Turn on the LED

} else {

digitalWrite(LED, LOW); // Otherwise, turn off the LED

}

Serial.println(intensity); // Print the light intensity to the Serial Monitor

delay(1000); // Wait for 1 second before taking the next reading

}

double intensity = light_intensity(analogRead(0));:It reads the light sensor value from analog pin 0, and the value is passed to thelight_intensityfunction to calculate the light intensity in lux.if (intensity < LowLightLimit):The code checks if the calculated light intensity is below the threshold (LowLightLimit = 200). If it is, the LED turns on.digitalWrite(LED, HIGH);:Turns on the LED (pin 7) if the intensity is below the threshold.digitalWrite(LED, LOW);:Turns off the LED if the intensity is greater than or equal to the threshold.Serial.println(intensity);:Prints the calculated light intensity value to the Serial Monitor for debugging.delay(1000);:Pauses for 1 second before repeating the process. This helps in controlling how frequently the light intensity is read and reported.

Finally Uploading Code to the Arduino

Measuring Light Intensity

Understanding Light Intensity

Various indicators of light are typically referred to as intensity:

1. Radiant intensity is a radiometric measure expressed in watts per steradian (W/sr).

2. Luminous intensity is a photometric measurement expressed in lumens per steradian (lm/sr) or in candela (cd).

3. Irradiance is a radiometric measurement expressed in watts per square meter (W/m2).

4. Intensity (physics), the term for irradiance applied in different areas of physics (W/m2)

5. Radiance, often referred to as "intensity" in the fields of astronomy and astrophysics (W·sr−1·m−2)

Displaying Readings on Serial Monitor

To display readings on the Serial Monitor, you usually employ the Serial.println() function in your Arduino code. Here is a short overview of how to accomplish this, along with a snippet of the code used for measuring light intensity.

```cpp

void loop() {

double intensity = light_intensity(analogRead(0)); // Read sensor value

Serial.println(intensity); // Print the light intensity value

delay(1000); // Wait for 1 second before repeating

}

```

1. Initializing Serial Communication: Before displaying any data, you must initialize serial communication in the setup() function using Serial.begin(9600);. This establishes the data rate (9600 bps, in this case) for communication.

2. Reading the Photoresistor Value: The code reads the analog value from the photoresistor, which is connected to an analog pin (in this example, pin 0). The light_intensity() function then converts this analog reading into a lux value for a more intuitive understanding of light levels.

3. Printing to the Serial Monitor: Use Serial.println(intensity); to output the calculated light intensity to the Serial Monitor. Each reading will appear on a new line, making it easy to follow changes over time.

4. Setting a Delay: Incorporating delay(1000); ensures that your system reads the sensor every second. This prevents the Serial Monitor from being flooded with data too quickly and gives you ample time to observe the values.

Monitoring Results

To view the output, you should:

- Open the Arduino IDE.

- Navigate to Tools > Serial Monitor or press

Ctrl + Shift + M. - Ensure the baud rate at the bottom of the Serial Monitor matches the one defined in your code (e.g., 9600).

As you modify the surrounding light near the photoresistor, you will see the related lux values displayed instantaneously. This enables swift assessments and modifications throughout your project development.

Calibrating Photoresistor Sensors

Importance of Calibration

1.Accuracy and Precision: Calibrating not only ensures sensor readings are accurate and in line with actual values, but it also guarantees precision by demonstrating a close grouping of repeated measurements.

2. Consistency: The calibration procedure ensures uniform measurement in sensors, improving the reliability and credibility of the data. This is especially important when implementing sensors in various environments and conditions.

3. Adhering to Standards: In various industries and scientific research domains, following international standards is essential to ensure the quality and reliability of sensor data. This guarantee is accomplished by executing rigorous calibration protocols.

4. Error Detection: Through consistent calibration, any inconsistencies or faults in the sensor are recognized, enabling prompt identification of problems that could jeopardize data quality.

5. Optimization and Efficiency: Improving overall effectiveness, precise sensors are vital in maximizing the performance of systems and processes. This is particularly crucial in sectors like manufacturing and processing, as it helps reduce waste.

6. Safety: In areas where safety is crucial, like aerospace or medical equipment, the accuracy of sensor data is essential. Calibration becomes an essential process in ensuring the safety and efficiency of these systems, considering their direct influence on human lives.

7. Scientific Integrity: The precision of gathered data significantly affects the reliability of experimental outcomes in scientific studies. Maintaining the integrity of scientific investigations and findings is vital through the important process of calibration.

8. Improved Decision-Making: In various scenarios, ranging from environmental oversight to industrial operations management, where faulty data can lead to misguided actions and outcomes, precise sensing is essential for well-informed decision-making.

Calibration Process and Techniques

1. Static Calibration

A critical aspect of sensor calibration, static calibration focuses on confirming the precision and linearity of the sensor's output within its operational range under stable conditions. This suggests that the input conditions, including temperature and pressure, stay unchanged during the calibration process.

Evaluation of Linearity

Linearity evaluation measures the degree to which a sensor's output linearly aligns with the input throughout its entire operational range, and it is an integral component of static calibration.

Method: A set of established inputs is applied to the sensor, and the related outputs are documented, following zero and span calibration. In a graph, the input values are represented on the x-axis while the output values are shown on the y-axis. Next, a best-fit line is created using the data points.

Evaluation: The linearity error of the sensor is indicated by the divergence of the data points from the optimal fit line. Within acceptable boundaries, the sensor is considered linear, enabling precise forecasting of its output throughout the operational range via a linear equation.

Correction: To allow the sensor output conversion to accurately represent input values, significant non-linearity errors are rectified through the use of calibration curves and mathematical models.

Static calibration guarantees the sensor's inherent accuracy and reliability under stable conditions by performing meticulous zero and span calibration along with linearity evaluations. Ensuring the fundamental precision of the sensor confirms that any variation in its output truly represents a shift in the measurand. This establishes a method for genuine and reliable measurements, essential for upholding the integrity of scientific research and the safety and efficiency of industrial processes.

2. Dynamic Calibration

Unlike static calibration, dynamic calibration measures the performance of sensors in situations where the input variables fluctuate quickly. Crucial for sensors operating in settings with changing or unstable conditions, this calibration technique ensures the dependability and accuracy of data obtained in real-time and various applications.

Phase Lag

A crucial factor in dynamic calibration, phase delay represents the duration needed for the sensor to respond to a variation in the input signal. Essential in real-time applications, where the sensor's quick identification of an event with minimal latency from its actual happening is critical.

Assessment: Assessment consists of applying a sinusoidal input to the sensor, measuring the time difference between the peaks of the input and output signals for further analysis.

Correction: To address significant phase delays, compensatory algorithms are utilized to synchronize the sensor's reaction with the true environmental variations.

In situations where inputs are variable and can shift rapidly, dynamic calibration is extremely important. In dynamic settings, the sensor's precision in identifying variations and its responsiveness is heavily reliant on accurate frequency response and reduced phase delay, which ensures the integrity of the data. Within the domain of rapid industrial operations and scientific investigations, where fleeting events are examined, it becomes essential. This examination greatly influences the dependability and accuracy of the final results.

Advantages and Disadvantages of Photoresistors

Advantages

1. Cost-Efficient: Photoresistors are generally less expensive to produce, rendering them a budget-friendly solution for light-detecting devices.

2. Simple Design: Their design is quite basic, featuring a light-sensitive semiconductor that allows for seamless integration into different digital circuits.

3. Energy Efficiency: In initiatives such as exterior lighting systems, photoresistors enhance electrical efficiency by automating the control of lighting depending on surrounding light levels.

4. Diverse Applications: Photoresistors are utilized across various sectors, demonstrating their flexibility and suitability for unique situations.

5. Real-time Detection: They respond to variations in low levels instantly, making them suitable for applications where immediate changes are crucial.

Disadvantages

1. Delayed Response Time: Photoresistors can exhibit a slower response time relative to certain other light sensors, limiting their utility in applications that need quick adjustments.

2. Temperature Sensitivity: They are responsive to changes in temperature, influencing their dark resistance and general performance.

3. Restricted Precision in Certain Uses: In applications that demand exact light measurement or specific spectral response, photoresistors may exhibit constraints.

4. Vulnerability to Environmental Influences: External factors like dust, dirt, or humidity can impact the performance of photoresistors as time progresses.

5. Restricted Spectrum of Response: Although photoresistors can detect light across a wide range, they face limitations in their spectral response, rendering them less ideal for applications that are sensitive to specific wavelengths.

Applications of Photoresistors

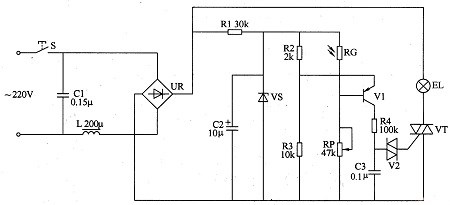

Dimming Control System

The illustration represents a standard light control dimming circuit. Its operating principle is as follows: when the ambient light diminishes, the resistance of the photoresistor increases, causing the voltage across the capacitor C to rise, thereby achieving the goal of boosting the voltage supplied to the lamp. On the other hand, if the external light increases in brightness, the resistance of RG will lower, leading to a reduction in the thyristor's conduction angle, which will simultaneously cause the voltage across the lamp to drop.

The rectifier bridge shown in the circuit above produces a DC pulsating voltage that cannot be filtered by a capacitor to achieve a smooth DC voltage.

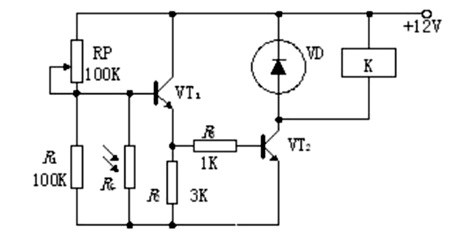

Light Switch

Numerous types of light-controlled switch circuits featuring relay-controlled outputs utilize photoresistors as essential components, including self-locking bright activation, dark activation, precise light activation, and dark activation.

This is a straightforward dark-excitation relay switching circuit. The operating principle is as follows: when the illuminance decreases to the predetermined level, VT1 activates because of the increased resistance in the photoresistor, resulting in the excitation current of VT2 making the relay operate, closing the normally open contact while opening the normally closed contact to control the external circuit.

Conclusion

In summary, using a photoresistor with Arduino to measure light intensity is a simple project that serves as a great method to grasp the basics of electronics and programming. Using a photoresistor, also known as an LDR (Light Dependent Resistor), together with basic circuitry, you can effectively track surrounding light levels and develop numerous applications, ranging from automatic lighting systems to sophisticated light-sensitive sensors in robotics.

The procedure entails measuring the varying analog voltage from the photoresistor as light intensity changes, allowing the Arduino to interpret this data for readability. This project acts as a perfect starting point for newcomers, providing them with practical experience in hardware interfacing and software programming.

Moreover, the adaptability of the Arduino platform allows for the addition of extra features, like data logging or connectivity with IoT devices, improving the project's capabilities. While working on this project, don't forget to come to Unikey and get the components you need.

Recommended reading:

How to Build a Sound Reactive LED Strip that Dances to Music