All You Want to Know: Different Kinds of Electronic Potentiometer Dials

In a busy audio engineering studio, sound technicians are carefully fine-tuning the sound levels for an important recording session. The audio equipments are well placed, the environment brims with creativity, where each detail is crucial in attaining the ideal blend. At the heart of this procedure are the electronic potentiometer dials incorporated into the mixing console. They provide exact control over volume and effects, allowing the engineers to adjust every track with remarkable precision. While the musicians perform with electric guitars, the technicians adjust the electronic potentiometer dials, effortlessly balancing the mix and improving the overall sound quality. Every adjustment of the dial alters the sound experience, highlighting the vital importance these tools have in contemporary audio creation. Using a range of potentiometers available to them, the team skillfully adjusts the settings, making certain that each note harmonizes flawlessly.

Historical Development of Potentiometers

Potentiometers (resistors) are groundbreaking electronic components that have progressed alongside the ongoing advancement of the electronics sector.

They possess a history spanning more than a hundred years. Soon after the introduction of Ohm's law in 1827, a basic and rudimentary variable resistor apparatus, the carbon pile resistor, was developed in the lab. This was the initial model of the potentiometer, which is commonly known today as the potentiometer (variable resistor).

In the 1920s, the emergence of radio, powered by electronic devices using electron tubes, resulted in the creation of synthetic carbon film and wire-wound variable resistors or potentiometers. Wire-wound potentiometers could handle greater power dissipation and exhibited high reliability in high-voltage circuits. In the 1940s, precise potentiometers featuring accurate linear properties were created, particularly for application in electronic analog computers.

The 1950s marked the rise of transistors, prompting potentiometers to develop toward reduced resistance and diminished contact noise to suit transistor circuits. This occurred because transistor circuits boosted current, while electron tube circuits increased voltage.

During the 1960s, the United States created conductive plastic potentiometers, and shortly after, the United Kingdom developed its own conductive polymers. Japan persisted in its research and development efforts, ultimately resulting in enhanced conductive plastic polymers, leading to more efficient and economical production.

Introduction to Electronic Potentiometers

Potentiometers, often referred to as "Pots" by engineers, are basically resistors equipped with a mechanical adjustment feature that allows for manual changes to their resistance. Resistors provide a constant resistance level and impede or “resist” the passage of electrical current within a circuit. A potentiometer is essentially a resistor that can vary.

Potentiometers act as voltage dividers, which can be employed to alter the voltage output for a circuit and precisely gauge (or meter) electrical potential – thus the term potentiometer. They generate a variable voltage output signal that is directly proportional to the position of the wiper on the resistive component. They are passive elements, indicating that they do not require power supply or extra circuits to operate.

The symbol of a Potentiometer is shown below:

The picture of a Potentiometer is shown below:

BOURNS 3314J-1-203E, find more, click here

Construction of Potentiometers

Potentiometers are made up of a resistive component, a movable contact (wiper) that glides over the component while establishing solid electrical contact with a section of it, terminals located at both ends of the component, a system that shifts the wiper from one end to the opposite, and a casing that encloses the component and wiper.

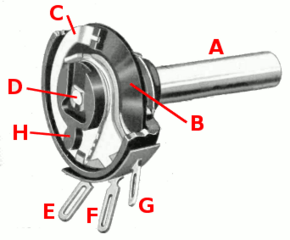

Numerous low-cost potentiometers are made with a resistive element (B in the cutaway illustration) shaped into an arc of a circle that is typically slightly less than a complete turn, along with a wiper (C) that moves across this element when turned, establishing an electrical connection. The resistive component may be either flat or slanted. Both ends of the resistive component are linked to a terminal (E, G) on the enclosure. The wiper is linked to a third terminal (F), typically positioned between the other two. In panel potentiometers, the wiper is typically the middle terminal of the three. In single-turn potentiometers, this wiper usually moves slightly less than one full revolution around the contact. The sole entry point for contamination is the tight gap between the shaft and the housing it turns within.

Another form is the linear slider potentiometer, featuring a wiper that moves along a linear component rather than rotating. Contamination can potentially infiltrate any point along the path of the slider's movement, which complicates effective sealing and undermines long-term reliability. One benefit of the slider potentiometer is that the position of the slider visually shows its setting. Although the position of a mark on the knob indicates the setting of a rotary potentiometer, a series of sliders can visually represent settings similar to those found in a graphic equalizer or the faders on a mixing console.

The resistive component of low-cost potentiometers is commonly composed of graphite. Additional materials utilized consist of resistance wire, carbon particles embedded in plastic, and a ceramic-metal composite known as cermet.

Conductive track potentiometers utilize conductive polymer resistor pastes comprising durable resins and polymers, solvents, and lubricants, along with the carbon that imparts the conductive characteristics.

Multiturn potentiometers function by rotating a shaft as well, but they require multiple turns instead of just one complete turn. Certain multiturn potentiometers feature a linear resistive component with a sliding contact that is adjusted by a lead screw; others are designed with a helical resistive component and a wiper that rotates through 10, 20, or more full turns, progressing along the helix as it spins. Multiturn potentiometers, whether user-accessible or preset, enable more precise adjustments; rotating through the same angle alters the setting by usually a tenth as much as for a basic rotary potentiometer.

A string potentiometer is a multi-turn device that functions by a connected wire reel rotating against a spring, enabling it to transform linear position into variable resistance.

Rotary potentiometers accessible to users can be equipped with a switch that typically activates at the counter-clockwise limit of rotation. Prior to the prevalence of digital electronics, such a component was utilized to enable radio and television receivers, along with other devices, to be powered on at a low volume with a noticeable click, followed by increasing the volume by rotating the same knob. Several resistance elements can be combined with their sliding contacts on a single shaft, such as in stereo audio amplifiers for adjusting volume. In other uses, like household light dimmers, the typical usage is most effectively achieved if the potentiometer stays in its existing position, thus the switch functions through a push mechanism, alternating on and off with axial presses of the knob.

Other potentiometers are housed within the device and are meant to be adjusted solely during the calibration of the equipment during production or servicing, and not otherwise interfered with. They are generally much more compact than user-accessible potentiometers and may require a screwdriver for operation instead of having a knob. They are typically referred to as "trimmer," "trim[ming]," or "preset" potentiometers (or pots), or the generic brand name "trimpot."

Difference Between Potentiometers and Rheostats

The simplest way to explain the difference between these two devices is that a potentiometer is a three-terminal device utilized for controlling voltage. A rheostat is a two-terminal instrument utilized for regulating current. Nevertheless, by merely disconnecting one leg of a potentiometer, you can utilize potentiometers as rheostats.

Rheostats are typically high-wattage, wire-wound variable resistors utilized in high current situations to manage current flow to devices like lamps and motors. They consist of coils made from durable wire that alter resistance in gradual increments by adjusting the position of the sliding component on the resistive element. Rheostats are defined not by their resistance value but by their capacity to manage high power levels.

Are Potentiometers and Rotary Encoders Identical to Each Other?

A rotary encoder is an instrument that transforms the angular position or movement of a shaft into a digital output. Potentiometers and rotary encoders both detect shaft rotation, yet they function on distinct principles, provide varying complexity levels, and necessitate different configurations.

Potentiometers are primarily analog instruments, although there are digital versions available. Rotary encoders are electronic devices that employ binary logic to specify position, thus requiring an additional circuit to convert their output into a practical signal.

Potentiometers provide simpler setup compared to rotary encoders, enable infinitely adjustable inputs, can split voltage non-linearly, and can effortlessly manage other ANALOG DEVICES. In contrast, rotary encoders can rotate endlessly, produce a digital signal, and provide outstanding resolution. Although they are generally pricier than potentiometers, their accuracy in motor control makes them particularly suited for industrial applications, automation, and robotics.

Types of Potentiometers

Let's delve into several common types, beginning with rotary potentiometers.

Rotary potentiometers

1. Singleturn pot

The Single Turn Pot can rotate to just one position, which is roughly 270 degrees or three-quarters of a full turn. Single Turn Potentiometer is primarily utilized in situations where a single turn offers sufficient control resolution.

2. Multi-Turn pot

The Multi-turn pots feature a wiper that is operated in a spiral or helical pattern, or through the use of a worm gear. Typically, these pots feature several rotation numbers such as 5, 10, or 20 to enhance precision. These pots are primarily utilized in applications such as trim pots on the PCB, which demand high precision and resolution.

3. Dual-gang pot

Dual gang pots are created by positioning two potentiometers side by side on a shared shaft, with single turn pots that have identical resistance and taper being the most commonly favored for this combination. Even though we can include more than two pots in the gangs, it is not very typical to do this. Employed in stereo audio volume regulation and various scenarios where 2 channels need simultaneous adjustment.

4. Concentric pot

The name itself indicates its function; it contains two potentiometers that can be individually adjusted using concentric shafts. This enables the user to possess two controls on a single unit to adjust two distinct resistances. These pots are primarily utilized in car radios where the volume and tone adjustments are combined.

5. Servo pot

A servo pot includes a servo motor linked to the pot, allowing the wiper to be automatically adjusted by operating the motor. This kind of pot is utilized in situations that necessitate both manual and automatic modifications, primarily in audio devices where a remote can adjust the volume control knob.

6. Presets and Trimmers

Trimmers, also known as trimpots, are a unique variety of rotary potentiometer that can be secured within a circuit and utilized for infrequent adjustments to the circuit. The rotary wiper on the POT can be modified with a small bladed screwdriver or a comparable plastic instrument. Common materials used for the resistive track include either carbon composition or cement. They can be found in both an open skeleton format and also assembled in a sealed square box.

Due to their affordability, compactness, and ease of use, they are primarily favored in non-essential circuit applications that need adjustments, tuning, and calibrations. The trimpots can be found in both single turn and multi-turn varieties, with a typical lifespan of merely 100-200 cycles. When a Trimmer functions as a variable resistor in a circuit, it is referred to as a Preset Potentiometer.

Linear potentiometers

Linear Potentiometer serves a similar purpose as the rotary potentiometer, but instead of having a semi-circular resistance, it features a linear resistor accompanied by a sliding contact. The linear resistor's two ends are linked to the source or input voltage, with the output collected between the sliding contact and either end of the linear resistor. Linear pots are frequently utilized to measure the voltage across a circuit branch, assess the internal resistance of a battery cell, and compare a battery cell against a standard cell.

Similar to Rotary Pots, linear pots come in various types suited for a range of applications. The various kinds of linear pots consist of slide pot, dual-slide pot, multi-turn slide, and motorized fader.

1. Slide Pot

The slide pot is a linear slider potentiometer, commonly known as the fader. The fader is made from conductive plastic. These are primarily utilized for audio applications and controlling or measuring distance in a single channel.

2. Dual Slide Pot

The Dual Slide Pot comprises one slider that allows for the simultaneous control of two potentiometers in parallel. They are frequently utilized for stereo management in professional sound systems and other uses that require control over dual parallel channels.

3. Multi-Turn Slide

The multi-turn slide features a spindle that triggers the wiper of the linear potentiometer, which allows for several rotations to enhance accuracy. They are frequently utilized in applications such as trim pots on the PCB, which demand high precision and resolution.

4. Motorized Fader

This is a kind of fader that can be automatically adjusted by a servo motor. These faders are utilized in scenarios that need both manual and automatic modifications. Primarily utilized in studio audio mixers, where the servo fader automatically adjusts to a stored setting.

digital potentiometers

A digital potentiometer (commonly referred to as digipot) is an electronic part that replicates the functions of analog potentiometers. Using digital input signals, the resistance between a pair of terminals can be modified, similar to an analog potentiometer. There are two primary functional categories: volatile, which lose their designated position when power is cut off and typically reset to the minimum position, and non-volatile, which maintain their specified position through a storage method akin to flash memory or EEPROM.

The application of a digipot is significantly more intricate than that of a basic mechanical potentiometer, and there are numerous constraints to consider; however, they are extensively utilized, frequently for factory precise calibration and precise adjustment of devices, particularly in situations where mechanical potentiometers present issues. A digipot is usually resistant to the impacts of moderate, prolonged mechanical vibration or environmental pollutants, similarly to other semiconductor devices, and can be electronically safeguarded against unauthorized alterations by restricting access to its programming inputs through various methods.

In devices equipped with a microprocessor, FPGA, or similar functional logic that can retain settings and reload them to the "potentiometer" whenever the device is turned on, a multiplying DAC may replace a digipot, providing improved setting resolution, reduced drift due to temperature, and greater operational versatility.

Membrane Potentiometer

A membrane potentiometer employs a conductive membrane that is altered by a sliding component to touch an adjustable voltage divider. Linearity may vary from 0.50% to 5% based on the material, design, and production method. The repeat accuracy generally ranges from 0.1 mm to 1.0 mm while having a theoretically limitless resolution. The lifespan of these potentiometer types usually ranges from 1 million to 20 million cycles, influenced by the materials employed in production and the actuation technique; both contact and contactless (magnetic) methods are offered (for position sensing). A variety of material options exist, including PET, FR4, and Kapton. Manufacturers of membrane potentiometers provide linear, rotary, and specialized variations for specific applications. The linear models may vary in length from 9 mm to 1000 mm, while the rotary models vary in diameter from 20 mm to 450 mm, with each one having a height of 0.5 mm. Membrane potentiometers are capable of being utilized for position detection.

For touch-screen devices that utilize resistive technology, a two-dimensional membrane potentiometer delivers x and y coordinates. The uppermost layer consists of thin glass positioned near an adjacent inner layer. The bottom of the upper layer features a transparent conductive coating, while the surface of the layer underneath is covered with a transparent resistive coating. A finger or stylus bends the glass to reach the layer beneath. The borders of the resistive layer feature conductive connections. Identifying the contact point involves applying a voltage to the opposing edges while the other two edges are temporarily disconnected. The voltage of the upper layer gives one coordinate. Detaching those two edges and applying voltage to the other two, which were previously unconnected, gives the other coordinate. Quickly switching between pairs of edges allows for regular position updates. An analog-to-digital converter delivers output data.

The benefits of these sensors are that they require only five connections, and the related electronics are relatively straightforward. Another factor is that any substance that compresses the upper layer over a limited space is effective. A drawback is that adequate force needs to be exerted to achieve contact. Another point is that the sensor needs periodic calibration to align touch position with the underlying display. Capacitive sensors do not need precise calibration or contact pressure; they simply require the proximity of a finger or another conductive item. Nonetheless, they are considerably more intricate.)

Materials Used for Potentiometers

Carbon composition ink shaped onto a substrate (phenolic resin). These are the most frequently used material with affordable price, and acceptable noise and durability features.

Wirewound pots are capable of managing high power. They are durable, and can be extremely accurate. They do, however, possess a constrained resolution and a coarse texture. This kind of material is primarily utilized in high power applications (rheostats are frequently wirewound) or as precision potentiometers.

Conductive plastic offers a very smooth texture and high resolution, and it can be designed to endure millions of cycles. They manage only a restricted amount of power and are costly. But thay are frequently used in premium (audio) devices where high resolution and minimal noise are essential.

Cermet is highly stable, exhibits a low temperature coefficient, and performs effectively at elevated temperatures. Conversely, they are rather costly and frequently restricted number of cycles permitted (there are also special long-lasting cermet pots available). It is often used for trimpots that require infrequent adjustments.

Characteristics of Potentiometers

1. The features and specifications of trimmer potentiometer

The primary features of a potentiometer include output function characteristics, alignment, resolution, and slide noise. The potentiometer's nominal resistance, permissible variation, rated power, and resistance temperature coefficient are identical to those of a resistor. The indicators of a potentiometer comprise its wear resistance lifespan and the initial torque.

2. Characteristics of the output function of a potentiometer

The relationship between the voltage ratio of the Bourns 3262 potentiometer (the ratio of output voltage to input voltage) and the stroke ratio (the ratio of brush to total stroke) is referred to as the law of resistance variation. Three frequently utilized functional relationships are linear, exponential, and logarithmic. Moreover, there are sine, cosine, and various other types appropriate for specific needs.

3. Conformance of the potentiometer

The extent of divergence between the real output function characteristics of the Bourns 3262 potentiometer and the theoretical value is indicated by the percentage of absolute difference between the actual output and the theoretical transmission. For linear potentiometers, conformity is indicated by linearity, and the permissible deviation range is referred to as linear accuracy.

4. Resolution of a potentiometer

The best adjustment capacity of the potentiometer for the output voltage or resistance indicates the output variation that can be generated by the slightest motion of the brush. It significantly affects the precision of the instrument or control system's precise calibration.

5. Sliding sound of Bourns 3262 potentiometer

The irregular parasitic potential generated by the brush sliding over the resistor (assuming the absence of thermal noise and current noise) manifests the sliding noise of the non-wire wound potentiometer as dynamic noise or smoothness, while the sliding noise of the wire wound potentiometer is represented by the equivalent noise resistance.

Advantages and Disadvantages of Potentiometer

Advantages of potentiometers include:

Basic Design

Potentiometers rank among the most straightforward electronic components accessible. Their fundamental structure includes a resistive component and a moving contact (wiper) that enables users to modify the resistance. This straightforwardness enables easy comprehension and integration into different circuits, making them an excellent option for applications that need simple voltage or current management.

Affordable Price

Potentiometers are typically more affordable than many other electronic parts. The mass manufacturing and extensive application in consumer electronics lead to their low cost. This affordability makes potentiometers available for both hobbyists and producers, allowing their application in a diverse range of devices from basic toys to intricate audio gear.

Extensive Resistance Range

Potentiometers come in a wide variety of resistance values, enabling designers to choose components that accurately fit their requirements. This adaptability guarantees that users can locate a potentiometer ideal for different applications, whether they need a low resistance to manage a small signal or a higher resistance for voltage dividers or signal reduction.

Simple and Effective Functioning

The functioning of potentiometers is straightforward. Users can effortlessly change the resistance through a rotary knob or slider, converting mechanical movement into an electrical signal. This user-friendliness is particularly advantageous in audio and video equipment, where rapid changes to volume or tone adjustments are often needed.

Different Configurations

Potentiometers are available in a range of configurations, such as single-turn and multi-turn varieties, along with rotary and slider designs. This variety enables designers to select the most suitable form factor for their particular application. Multi-turn potentiometers allow for precise adjustments, whereas slider types enable tactile interaction in user interfaces.

Established Technology

Potentiometers have been utilized in electronics for many years, leading to a comprehensive understanding of their performance traits. This background instills confidence in designers, enabling them to depend on established technology to operate dependably across different applications.

Logarithmic and Linear Taper Choices

Potentiometers may feature either linear or logarithmic taper properties, allowing them to be used in various applications. For example, audio devices frequently use logarithmic taper potentiometers since human hearing detects sound intensity on a logarithmic scale, facilitating more natural volume changes.

Disadvantages of potentiometers include :

Restricted Bandwidth

Potentiometers can cause bandwidth constraints in high-frequency settings. Their mechanical characteristics can create inductance and capacitance that influence signal integrity at high frequencies. As a result, they aren't the ideal option for high-speed digital signals or RF applications.

Restricted Current Handling Capacity

In contrast to rheostats, which are intended for managing higher currents, potentiometers typically possess low current ratings. Surpassing these ratings may result in overheating and irreversible harm. This limitation requires thorough evaluation of potentiometer specifications in scenarios with substantial current flow.

Mechanical Wear and Contamination

The components of potentiometers (the wiper and the resistive path) can deteriorate with time, resulting in greater resistance fluctuations and erratic performance. Moreover, they are vulnerable to pollution from dust, dirt, and moisture, which can affect their performance. This mechanical degradation is especially troublesome in uses that demand regular modifications.

Electrical Noise Production

When using a potentiometer, especially with a contaminated or worn track, electrical noise may occur. This noise appears as crackling or scratching noises in audio applications, potentially undermining the intended performance. Users should maintain cleanliness and proper upkeep to reduce these impacts.

Restricted Rotational Angles for Single-Turn Pots

Single-turn potentiometers possess a mechanical rotation constraint of under 270 degrees. This constraint may limit the variety of modifications accessible to users, especially in applications demanding precise control. Multi-turn potentiometers can address this problem, although they tend to be costlier.

Reactivity to External Influences

Potentiometers might be influenced by external mechanical pressures, like vibrations or impacts, that could result in unintentional modifications. This sensitivity may affect their dependability in situations exposed to extreme conditions or physical motion.

Possibility of Electrical Noise Production

The mechanical movement of the potentiometer controls may occasionally create electrical noise, especially if the resistive track is contaminated or the component is aged. This sound may appear as crackles or pops, particularly in audio settings, which can negatively impact performance.

Functional Characteristics of Potentiometer Dials

Potentiometer dials act as vital elements in numerous electronic uses, enabling users to modify resistance and regulate voltage output. Below are several important functional features of these devices:

- Variable Resistance: At the heart of their operation, potentiometer dials allow for the modification of resistance in a circuit, rendering them crucial for uses such as audio control, light level adjustments, and sensor tuning.

- Taper Types: Potentiometers are available in various taper types, mainly linear and logarithmic. Linear potentiometers offer a consistent change in output when the dial is rotated, while logarithmic (or audio) potentiometers alter output more swiftly at one end, addressing the logarithmic nature of sound perception.

- Wiper Mechanism: The wiper, a sliding contact that traverses the resistive element, establishes the voltage output. The fluidity and accuracy of this motion greatly affect the user experience, and innovations in design focus on reducing noise and improving durability.

- Digital vs. Analog: Electronic potentiometers can be divided into analog and digital varieties. Although analog potentiometers offer continuous precise adjustment, digital potentiometers use a set of distinct steps, enabling accurate regulation through microcontrollers and digital technologies.

- Noise Characteristics: The noise characteristics can be used to evaluate a potentiometer's quality. Sliding noise, commonly found in different kinds of potentiometers, may compromise signal integrity. Advancements in manufacturing methods have aimed at minimizing this noise to improve overall efficiency.

Operational Principles of Potentiometer Dials

The functional principles of potentiometer dials rely on Ohm's Law and the resistance characteristics of materials. When a pot dial is rotated, the wiper slides along a resistive path, changing the resistance faced by the electric current traveling through the circuit.

- Voltage Division: At its essence, a potentiometer acts as a voltage divider. The output voltage correlates with the position of the wiper, which splits the total resistance between both ends. Therefore, the modified voltage can be employed in different areas of a circuit.

- Feedback Loops:In various applications, potentiometers are utilized in feedback loops to enable control systems. For instance, in motor speed controllers, the control knob modifies the control electrical signal, directly affecting the motor's functioning.

- Precise Calibration and Adjustment: Potentiometers play a crucial role in the precise calibration of electronic devices. By modifying the potentiometer, you can refine the circuit performance to meet defined specifications, guaranteeing precision in accurate measurements or results.

- Interaction with Microcontrollers: As digital electronics advance, potentiometers can be connected to microcontrollers. In this configuration, the analog output from the potentiometer is transformable into a digital value, enabling accurate modifications and programmable management in numerous applications such as LED dimming and audio mixing.

What Does a Potentiometer Do?

Physical Mechanism of Action

The resistive element is a constant part with a predetermined resistance value, usually formed as a curved or linear track. The wiper, functioning as a sliding or rotating contact, travels along this path. When you rotate the knob of the potentiometer or slide its lever, the wiper shifts, altering its location along the resistive material.

The resistance of an object depends on various factors. When everything else is unchanged, the resistance of an object is directly related to its length. To put it differently, an item made of identical material and having the same cross-sectional area that measures 10 centimeters in length will have half the resistance of a similar item that is 20 centimeters in length. This principle is utilized by potentiometers. The variable output of a potentiometer is achieved by changing the linear or rotary position of a sliding contact over a consistent resistance element, altering the distance that current travels through. The input voltage is applied along the full length of the resistive component, while the output voltage is measured as the drop between the stationary resistive component and the sliding or rotating contact. The location of the movable contact along the resistive element dictates the level of input voltage that will be introduced to the circuit.

Potentiometers are seldom utilized to manage over a watt because the device needs to dissipate the input power, resulting in excessive heat. They instead function by modifying analog signals utilized by other elements to manage power. For instance, a basic light dimmer employs a potentiometer to manage a TRIAC that adjusts the light intensity.

Potentiometers are infrequently employed to directly manage substantial power levels (over a watt or so). Rather, they are utilized to modify the intensity of analog signals (such as volume adjustments for audio equipment) and as control inputs for electronic circuits. For instance, a light dimmer utilizes a potentiometer to manage the switching of a TRIAC, thereby indirectly regulating the illumination of lamps.

Preset potentiometers are commonly utilized in electronics whenever modifications are needed during production or maintenance.

User-operated potentiometers are commonly utilized as controls by users and can manage a broad range of equipment functions. The common use of potentiometers in consumer electronics decreased in the 1990s, as rotary incremental encoders, up/down buttons, and other digital controls became more prevalent. Nonetheless, they continue to be utilized in various applications, including volume adjustments and position sensing.

Application

Sound management

Low-power potentiometers, whether slide or rotary, are utilized to regulate audio devices, adjusting volume, frequency reduction, and various attributes of audio signals.

The 'log pot', referring to a potentiometer, features a resistance taper or "curve" that follows a logarithmic (log) pattern. It serves as the volume control in audio power amplifiers and is often termed an "audio taper pot" since the human ear's amplitude response is roughly logarithmic. It guarantees that on a volume control range of 0 to 10, for instance, a level of 5 is perceived as half as loud compared to a level of 10. There is also a reverse audio taper pot or anti-log pot, which is essentially the opposite of a logarithmic potentiometer. It is frequently utilized in a ganged setup alongside a logarithmic potentiometer, such as in an audio balance adjustment.

Potentiometers combined with filter networks function as tone controls or equalizers.

In audio systems, the term linear is occasionally used in a misleading manner to refer to slide potentiometers due to the linearity of the physical sliding action. The term linear, when used with a potentiometer, whether it is slide or rotary, denotes a linear correlation between the position of the pot and the accurate measurement from its tap (wiper or electrical output) pin.

Television

Potentiometers are used for adjusting picture brightness, contrast, and color response. A potentiometer was frequently utilized to modify "vertical hold," influencing the synchronization between the receiver's internal sweep circuit (occasionally a multivibrator) and the received video signal, as well as other elements like audio-video carrier offset, tuning frequency (for push-button models) and similar factors. It also aids in the frequency modulation of waves.

Movement regulation

Potentiometers serve as position feedback devices to establish closed-loop control, as seen in a servomechanism. This technique for motion control is the most straightforward channel to measure the angle or displacement.

Transducers

Potentiometers are commonly utilized in displacement transducers due to their simple construction and ability to produce a significant output signal.

Calculation

In analog computers, precise potentiometers are employed to adjust intermediate outcomes by specified constant factors or to establish initial conditions for calculations. A motorized potentiometer can function as a signal generator by utilizing a non-linear resistance card to provide estimates of trigonometric functions. For instance, the rotation of the shaft could symbolize an angle, and the voltage division ratio might be adjusted to be proportional to the cosine of that angle.

Potentiometer Size

The size of a potentiometer are a crucial factor in numerous applications, affecting both the overall design of the electronic device and its functionality and performance. Sizes can differ greatly, ranging from tiny versions appropriate for small devices such as smartphones to bigger, durable types utilized in industrial uses.

Miniature Potentiometers

Miniature potentiometers are typically used in space-constrained environments where circuit board real estate is at a premium. These small potentiometers often come in surface-mount or through-hole designs, and they may be offered in both rotary and slide formats. Their compact nature makes them ideal for consumer electronics, such as portable audio equipment and handheld devices, providing tactile feedback without taking up excessive space.

Standard Size Potentiometers

The standard-sized potentiometers are the most commonly encountered types and are versatile across various applications. These are generally used in consumer electronics such as audio gear, televisions, and home appliances. Standard potentiometers provide a balance of size, durability, and functionality, making them suitable for consumers who require reliable performance without the need for miniaturization.

Large Potentiometers

Large potentiometers are designed for heavy-duty applications, frequently found in machine controls, power supplies, and industrial equipment. These potentiometers typically feature robust designs that can withstand higher wear and tear, making them suitable for environments where durability is paramount. They often have higher power ratings and are built to handle significant load without compromising performance.

Potentiometer Selection

Selecting the right potentiometer is crucial for ensuring optimal performance in your electronic projects. Here are key factors to consider:

1. Type of Potentiometer

Rotary vs. Linear

Decide if your device requires a rotary potentiometer (twist motion) or a linear potentiometer (slide motion) considering the user interface and ergonomics.

Digital vs. Analog

Choose between a digital potentiometer, which interfaces with microcontrollers, or an analog type, which provides direct voltage adjustment.

2. Resistance Value

The resistance rating of a potentiometer influences its load and sensitivity. Typical values vary from a few ohms to multiple megaohms. Choose a value that meets your circuit needs— greater resistance lowers power use but might raise noise levels.

3. Taper Type

Linear vs. Logarithmic: Choose between linear taper (uniform change throughout its range) or logarithmic taper (greater sensitivity in specific ranges, frequently employed in audio settings where volume adjustments need to be more noticeable at lower levels).

4. Power Rating

Every potentiometer possesses a maximum resistance (commonly expressed in watts). Make sure the potentiometer can manage the power it will release in your circuit to prevent malfunction.

5. Physical Size and Mounting Style

Select a potentiometer that is suitable for the design space of your device (e.g., surface mount, through-hole, or panel mount). Ensure that its size and mounting method are appropriate for the intended use.

6. Temperature and Environment

Take into account the environmental factors in which the potentiometer will function, such as temperature variations and moisture levels. This guarantees lasting power and dependability in your application.

7. Wiper Configuration

Decide if a single or multi-turn potentiometer is necessary based on the precision and resolution demands of your application.

8. Cost and Availability

Finally, evaluate your budget and the accessibility of the potentiometer in the marketplace. Choose trustworthy suppliers to guarantee quality and dependability.

By carefully considering these factors, you can select a potentiometer that meets the specific needs of your electronic circuit, thus enhancing its overall functionality and performance.

Potentiometer Pinout

When incorporating an electronic potentiometer into your circuit, grasping the pinout arrangement is essential for optimal functionality. The pinout denotes the layout and role of the pins on the potentiometer, which are vital for its functionality.

Most potentiometers come with three terminals:

Terminal 1 (Wiper)

This is the movable pin that delivers an output voltage that changes based on the wiper's position. It links to the circuit in which you wish to control voltage.

Terminal 2 (Final Terminal A)

This pin links to one side of the resistive component. It is usually linked to the voltage source or the ground, based on the usage.

Terminal 3 (End Terminal B)

This pin connects to the opposite end of the resistive component. It frequently pertains to the load that needs the regulated voltage.

Wiring and Configuration

Wiring Configurations for Potentiometers

In more intricate applications of potentiometers, there are various advanced wiring setups to take into account. These configurations can improve functionality and connect potentiometers with other electronic elements such as microcontrollers.

1. Precision Voltage Divider

Objective: Attain accurate voltage division for delicate applications.

Configuration:

Terminal 1 connected to Vcc.

Terminal 3 to ground.

Terminal 2 (wiper) connects to a high-impedance input (like an analog-to-digital converter, ADC, found in a microcontroller).

Application: Utilize in signal conditioning circuits to modify sensor outputs.

2. Potentiometer with Buffer Amplifier

Objective: Separate the potentiometer from the load to avoid loading impacts.

Configuration:

Connect the potentiometer in a conventional voltage divider configuration.

Link the wiper (Terminal 2) to the input of an operational amplifier (op-amp) set up as a buffer (voltage follower).

Application: Utilize in audio applications to preserve signal integrity.

3. Dual Potentiometers for Differential Measurement

Aim: Assess the variance between two signals.

Setup:

Utilize two potentiometers, with both set up as voltage dividers.

Attach the wiper terminals of each potentiometer to the inputs of a differential amplifier.

Usage: Employ in scenarios that necessitate accurate differential measurements, like strain gauge circuits.

4. Microcontroller Integration

Objective: Connect potentiometers to microcontrollers for digital management and observation.

Setup:

Terminal 1 connected to Vcc.

Terminal 3 to the ground.

Connect Terminal 2 (wiper) to an ADC pin of the microcontroller.

Application: Utilize in user interfaces for digital parameter adjustments, like configuring thresholds or fine-tuning control loops.

5. Feedback Control Loop

Aim: Incorporate feedback in control systems.

Configuration:

Utilize the potentiometer as a sensor for position or angle.

Attach the wiper to an ADC input on a microcontroller.

Utilize the ADC measurement in the microcontroller's control system to modify actuators.

Usage: Implement in robotic arms or servo systems to deliver precise position information.

Tips for Optimizing Project Performance

When using electronic potentiometer dials in your projects, optimization is important for attaining dependable and accurate performance. The following comprehensive guide will help you to improve your designs while making sure that the potentiometers operate smoothly in their designated functions.

1. Selecting the Appropriate Type of Potentiometer

Choosing the right kind of electronic potentiometer is essential. Evaluate if your application requires a digital or an analog potentiometer. Digital potentiometers are perfect for projects that need remote modifications and automation because of their digital interface, while analog potentiometers are better for simpler, continuously adjustable uses.

2. Employing Quality Components

Investing in superior components can greatly enhance the performance of your circuits. Make sure the potentiometers you select are capable of managing the voltage and current levels required for your applications. Enhanced specifications can result in better durability and accuracy in voltage regulation.

3. Executing Appropriate Circuit Design

A carefully planned circuit design is essential for enhancing the performance of electronic potentiometer knobs. Please ensure to:

Reduce Signal Loss: Employ shorter wiring and strategically route traces on your PCB to minimize potential noise disruptions.

Isolate Inputs: Utilize buffering or isolation methods to protect the input signal from potential load interference, ensuring signal integrity is preserved.

4. Adjustment and Evaluation

Consistent calibration of your potentiometer knobs can improve precision. This includes modifying the output measurements to match established standards. In conjunction with comprehensive circuit testing, calibration guarantees that the potentiometer reacts precisely across various conditions.

5. Monitoring Data in Real-Time

Employing a microcontroller for real-time oversight can enhance efficiency when interfacing with potentiometers. Examining the current readings facilitates the rapid detection of discrepancies, enabling immediate modifications to enhance overall performance.

6. Utilizing Error Correction Techniques

In systems utilizing potentiometers in feedback control loops, incorporating error correction algorithms can markedly improve control precision. Techniques like predictive algorithms can assess possible variations and automatically modify settings to maintain intended performance standards.

7. Incorporating with Extra Technologies

Think about incorporating additional technologies such as feedback sensors or wireless communication modules alongside your potentiometers. This offers improved features, including remote management and observation, thereby enhancing the overall performance of your project.

Conclusion

In conclusion, electronic potentiometer dials are essential for the versatility and performance of electronic circuits. As technology becomes increasingly integrated into everyday devices, it is crucial to understand the basic concept of different types of potentiometers that are available. From the basic decision between digital and analog models to the subtle distinctions in resistance values, potentiometer taper types, and power ratings, every feature greatly influences performance and user satisfaction.

Choosing the appropriate potentiometer involves more than just function; it also takes into account aspects like physical dimensions, installation type, and environmental influences that affect the device's durability and dependability. In situations where precision is crucial, the choice between single-turn and multi-turn potentiometers can lead to significant variations in user control and accuracy.

Moreover, understanding budget limitations and market access allows designers and engineers to obtain quality electronic components without sacrificing potentiometer performance. Considering these crucial factors allows you to enhance the performance of your electronic circuits, addressing present requirements as well as future growth.

The domain of electronic potentiometer dials is abundant with choices, enabling customized solutions for diverse applications, ranging from consumer gadgets to industrial equipment. By spending time to deeply comprehend these elements, you can not only improve the performance of your projects but also support the sustainability and effectiveness of electronic systems in our ever more interconnected world. Investigate the various options on offer, evaluate your particular needs, and make an informed choice to guarantee the best outcomes in your electronic pursuits.