Symbol of Varistor: From Theory to Practice

In my everyday routine, I frequently utilize different electronic gadgets, ranging from laptop to kitchen tools. Nonetheless, one will inevitably face some severe weather conditions. When thunderstorms occur, Varistors come into play. In the course of these storms, power spikes may happen, endangering the reliability of devices. To safeguard electronics, I use a surge protector equipped with a varistor. It stays inactive during standard voltage conditions, permitting electricity to pass smoothly to devices. Nevertheless, when a voltage surge happens because of the storm, the Varistor swiftly clamps down, lowering the voltage to a safe level and avoiding possible harm to my beloved electronics. This unseen protector is vital for keeping my devices secure and operational in the face of nature's uncertainties.

History of Varistors

The creation of the varistor, as a new variety of rectifier utilizing a cuprous oxide (Cu2O) layer on copper, began with the research of L.O. Grondahl and P.H. Geiger in 1927.

The copper-oxide varistor showed a change in resistance based on the polarity and strength of the applied voltage. It was made from a small copper disc, with a layer of cuprous oxide formed on one side. This setup allows for minimal resistance to current moving from the semiconducting oxide to the copper side, yet presents a high resistance to current flowing in the reverse direction, with the immediate resistance changing continuously based on the voltage applied.

During the 1930s, compact multiple-varistor units with a maximum size of under one inch and seemingly unlimited lifespan were utilized to substitute large electron tube circuits as modulators and demodulators in carrier current systems for telephone transmission.

Additional uses for varistors in the telephone system involved safeguarding circuits against voltage surges and interference, along with minimizing clicks in receiver (ear-piece) components to shield users' ears from popping sounds during circuit switching. These varistors were made by stacking an equal number of rectifier disks and linking the terminal ends and the center in an anti-parallel arrangement, as illustrated in the image of a Western Electric Type 3B varistor from June 1952.

The 1949 Western Electric type 500 telephone introduced a dynamic loop equalization circuit that utilized varistors to divert higher levels of loop current on short central office loops, automatically adjusting both transmission and reception signal levels. In lengthy loops, the varistors upheld a fairly high resistance and did not change the signals much.

A different kind of varistor was developed from silicon carbide (SiC) by R. O. Grisdale during the early 1930s. It was employed to protect telephone lines from lightning.

In the early 1970s, researchers in Japan identified the semiconducting electronic characteristics of zinc oxide (ZnO) as advantageous for a new type of varistor in a ceramic sintering method, demonstrating a voltage-current behavior akin to that of two Zener DIODES placed back-to-back. This kind of device emerged as the favored solution for safeguarding circuits against power surges and various harmful electrical disturbances, and it became widely recognized as the metal-oxide varistor (MOV). The random alignment of ZnO grains within this material created identical voltage-current properties for both directions of current movement.

Additional uses for varistors in the telephone system involved safeguarding circuits against voltage surges and interference, along with click suppression on receiver (ear-piece) components to shield users' ears from popping sounds during circuit switching. These varistors were created by stacking an equal number of rectifier disks and linking the terminal ends and the center in an anti-parallel setup, as illustrated in the image of a Western Electric Type 3B varistor from June 1952.

Definition of Varistors

A varistor is an electronic component that protects against surges, featuring electrical resistance that changes based on the voltage applied. It possesses a nonlinear, non-ohmic current-voltage behavior akin to that of a diode. In contrast to a diode, it exhibits the same property for current flow in both directions. Historically, varistors were made by linking two rectifiers, like the copper-oxide or germanium-oxide rectifier, in an antiparallel arrangement. At low voltage, the varistor exhibits high electrical resistance, which diminishes as the voltage increases. Contemporary varistors mainly rely on sintered ceramic metal-oxide substances that demonstrate directional properties solely at a microscopic level. This variety is widely referred to as the metal-oxide varistor (MOV).

Varistors serve as control or compensation components in circuits to ensure optimal operating conditions or to safeguard against excessive transient voltages. When utilized as safeguarding devices, they redirect the current generated by excessive voltage away from delicate components upon activation.

The term varistor is a combination of varying and resistor. The phrase is solely applied to non-ohmic variable resistors. Variable resistors, including the potentiometer and the rheostat, exhibit ohmic properties.

part number B72214S0321K101, provided by TDK (more products can be found here)

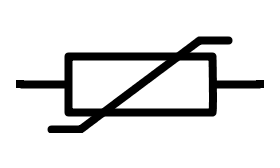

The standard symbol of varistor is shown below:

Key Characteristics of Varistors

The Voltage-Current Graph with Nonlinear Characteristics

Varistors are recognized for their unique voltage-current (V-I) traits, presenting a nonlinear curve. This curve is essential for comprehending how a varistor reacts to voltage variations. At standard operating voltages, the varistor exhibits elevated resistance, guaranteeing that only a small amount of current passes through it. Nonetheless, when exposed to voltage spikes, its resistance drops significantly. This allows it to carry high currents and safeguard delicate components by restricting voltage surges to safe limits. This nonlinear response is crucial for absorbing temporary spikes without incurring harm.

The Capability to Control High Surge Currents

A standout characteristic of varistors is their capacity to manage elevated surge currents(maximum current that passes through the varistor). Varistors are engineered to safeguard circuits from voltage surges due to lightning strikes, switching activities, or other disruptions, allowing them to temporarily absorb and release significant energy. This ability to withstand high current is vital for protecting delicate electronic equipment, rendering varistors key elements in surge protection devices.

Reproducibility

Varistors are appreciated for their consistency, indicating that their performance traits stay uniform across various units. This dependability enables engineers and manufacturers to create circuit protection systems with assurance, aware that each varistor will perform alike in standard conditions. This uniformity not only streamlines design procedures but also improves the safety and efficiency of electrical systems across different applications.

The Two-Faced Protection

In various applications, varistors offer a twofold protection against voltage surges. This indicates they are capable of safeguarding equipment in both directions, regardless of whether a voltage surge comes from the line side or the load side. This adaptability guarantees thorough safeguarding, thereby extending the lifespan of electronic gadgets and minimizing the chances of operational failures from transients.

Fast Reaction Time

Varistors are well-known for their rapid response time, which is crucial in situations where every millisecond is important. When a voltage spike happens, varistors can respond nearly immediately, transitioning from a high resistance condition to a low resistance condition. This swift response reduces the effects of high-voltage surges, safeguarding delicate electronics and ensuring operational stability.

The Deterioration Procedure

Although they are effective, varistors can experience deterioration over time, especially following repeated exposure to high-energy surges. Every surge can somewhat reduce their protective functions, resulting in higher leakage currents and a decrease in clamping voltage. Consequently, it is essential for designers to take into account the lifecycle of varistors in their applications, making sure to perform regular inspections or replacements to uphold peak performance and safety standards.

Mechanism of Varistors

Varistors operate by lowering their resistance when the voltage applied to them rises. This characteristic makes them ideal for protecting electronic circuits from overvoltage and transient voltage occurrences. Usually positioned in parallel to the circuit that needs protection, varistors are essential for restricting current flow during transient occurrences, thus safeguarding the electronics in the circuit from damage.

Varistors are particularly efficient in safeguarding against lightning. In this application, multiple varistors are arranged in parallel and thoughtfully positioned on or close to electronic devices at risk of lightning damage. In the event of a lightning strike, the combined varistors restrict the current passing through the device, safeguarding against possible damage.

Moreover, varistors are useful for safeguarding electronic circuits against voltage spikes caused by switching power supplies and inductive loads. In these instances, varistors are added in series with the circuit that needs protection. When a transient voltage event happens, the varistor's reduced resistance limits the current in the protected circuit, protecting the electronics from possible harm.

The efficacy of a varistor in protecting a circuit from transient voltage occurrences depends on its clamping voltage. The clamping voltage is the highest voltage that a varistor can tolerate without experiencing breakdown and creating a short circuit. This essential parameter is affected by aspects like the varistor's material makeup, shape, and rated current.

The Role of Varistors in Voltage Protection

Varistors are vital for protection in circuits, acting as key elements in safeguarding electronic devices from harmful voltage fluctuations. Their ability to dampen voltage spikes is essential in various applications, spanning from household devices to industrial machinery.

Voltage Dependent Resistance Explained

The key feature of a varistor's functioning is its voltage dependent resistance. This unique characteristic allows the device to sustain elevated resistance during normal operating conditions, effectively preventing current from flowing through it. However, when a voltage surge occurs, the varistor's resistance significantly decreases, permitting the excess current to pass through. This system enables varistors to protect sensitive electronic components from damage caused by transient voltage events.

Protection Against Voltage Spikes

Varistors are specifically engineered to protect against voltage spikes. By absorbing and redirecting bursts of electrical energy, they minimize the risk of damage to circuits and devices. This characteristic ensures that electronic systems operate reliably, providing confidence to both producers and consumers. Varistors are essential in any voltage protection plan because of their inherent ability to quickly respond to high voltage levels.

Types of Varistors

Metal Oxide Varistors (MOVs)

Metal Oxide Varistors, a very common type, are voltage dependent resistors featuring symmetrical voltage-current characteristics, intended to safeguard various electronic devices or components from switching and lightning surges. It can also be called Voltage Dependent Resistor.A Metal Oxide Varistor is composed of a sintered arrangement of zinc oxide grains, creating a configuration akin to a diode junction.Its non-linear exponent feature, alongside the use of range and mass production, is increasingly being adopted across different levels of electrical engineering.

The characteristics of Metal Oxide Varistors include:

1. Fast Response Time

A notable characteristic of varistors, especially Metal Oxide Varistors (MOVs), is their rapid response time. During a transient voltage event, MOVs can transition from a high-resistance state to a low-resistance state within microseconds. This immediate reaction stops high voltage surges from impacting delicate electronic parts, thereby offering essential safeguarding during voltage fluctuations. By reducing the time spent under high voltages, varistors aid in maintaining the safety and efficiency of connected devices.

2. Negligible Leakage Current

Another important benefit of varistors is their low leakage current while operating under normal conditions. In contrast to other protective devices that may permit considerable current flow even under normal circumstances, varistors stay in a non-conductive state when the voltage is within the safe limits. This feature minimizes unnecessary energy loss and improves overall energy efficiency in electronic systems. By keeping leakage current minimal, varistors not only safeguard devices but also help reduce operational expenses.

3. Excellent Voltage Ratio

Varistors are designed to handle a wide variety of voltage levels, rendering them highly adaptable components in numerous applications. Their excellent voltage ratio enables them to function efficiently in settings where voltage levels vary. This characteristic is crucial for guaranteeing that the protection provided by varistors remains effective under different electrical conditions, allowing their use in applications ranging from home systems to industrial equipment.

4. Wide Voltage and Energy Ratio

The ability of varistors to handle various voltage and energy levels is crucial for situations where different electrical conditions are present. This wide range of voltage and energy allows varistors to manage minor spikes and significant surges without affecting their protective capabilities. The versatility of varistors broadens their application in numerous industries, such as telecommunications, automotive, and consumer electronics, where dependable voltage protection is crucial.

5. Minimal Standby Energy and No Following Current

One major advantage of utilizing varistors is their capacity to use very little standby power. When inactive, they do not consume current, making them an efficient option for protective circuits. Furthermore, after a surge event concludes, varistors quickly revert to their non-conductive condition, preventing any further current from passing through. This quick reevaluation of resistance not only saves energy but also improves the dependability of the systems they safeguard.

6. Outstanding Achievement in Surge Current Control

Varistors are especially well-known for their outstanding ability to manage surge currents. They are capable of absorbing and dispersing significant energy during voltage surges while preserving their structural integrity. This resilience is vital for safeguarding delicate electronic components against events like lightning strikes or switching surges, which could otherwise result in disastrous failures or expensive damage.

7. Excellent Clamping Voltage Characteristics

The clamping voltage indicates the voltage point at which a varistor starts to conduct, redirecting the surge current from the circuit being protected. Varistors are designed to possess outstanding clamping voltage properties, allowing them to successfully restrict voltage surges to safe thresholds. This feature improves the safety and durability of the components they safeguard and is a crucial reason for their widespread use in voltage protection applications.

Silicon Carbide Varistors

At one point, this was the most prevalent type prior to the MOV being introduced to the market. These parts make use of silicon carbide (SiC). They have been extensively utilized in applications involving high power and high voltage. The drawback of these devices is that they consume a considerable standby current. Hence, a series gap is necessary to restrict the standby power usage.

Silicon Carbide (SiC) varistors stand out in several important areas, rendering them extremely efficient for particular uses, especially in high-voltage and high-power settings. Presented here are several significant traits:

1. Self-Healing

A major characteristic of silicon carbide varistors is their ability to recover on their own. Following a voltage spike, these devices can revert to their original non-conductive state without needing outside assistance or replacement. This capability not only guarantees continuous safeguarding for the circuit but also improves the overall resilience and dependability of the electronic system.

2. Adaptability in Ecological Settings

Silicon carbide varistors are utilized in numerous environments, such as air, oil, and sulfur hexafluoride (SF6). This adaptability enables them to function effectively in various environmental settings, rendering them appropriate for a wide array of uses from industrial equipment to high-voltage energy systems.

3. Modular Structure

These varistors can be configured as separate units or combined into modular setups. This design flexibility allows engineers to customize their solutions to meet particular circuit needs, enhancing the overall system's performance while avoiding unnecessary complexities.

4. Elevated Ampacity

Silicon carbide varistors feature an impressive ampacity, enabling them to manage significant current amounts. This attribute renders them especially useful in situations where large spikes might happen, guaranteeing their ability to safeguard delicate electronic parts without suffering from deterioration or breakdown.

5. Enhanced Surge Energy Rating

Featuring a high surge energy rating, SiC varistors can absorb and disperse significant energy during transient voltage spikes. This feature not only protects connected devices from harm but also extends the durability of the circuits in which they are incorporated.

6. 100% Active Ingredient

The varistors are made from silicon carbide materials that contain 100% active components. This indicates that the materials display outstanding non-linear electrical properties that facilitate efficient voltage suppression, guaranteeing that the varistor functions dependably across a wide range of operating conditions.

7. Replicable Non-Linear Features

The electrical properties of silicon carbide varistors exhibit consistent non-linear behavior. This steady performance is vital for delivering dependable surge suppression and guarantees reliable function in recurring surge situations, establishing them as a reliable option for engineers when designing protective circuits.

8. Endurance at High Voltage

Ultimately, silicon carbide varistors are designed to withstand elevated voltage levels. Their inherent characteristics aid in their capacity to endure considerable electrical stress, vital in situations related to high-voltage transmission lines and other essential infrastructure.

Advantages and Disadvantages of Varistor Symbols

Benefits of Varistors

Effective Protection Against Voltage Surges

A key benefit of utilizing varistors is their capacity to effectively clamp high voltage levels, thus safeguarding delicate electronic components. By quickly reacting to voltage spikes, they assist in protecting the integrity of connected devices, ensuring their operation and safeguarding them from possible harm.

Quick Reaction Time

Varistors are recognized for their quick response times, responding nearly immediately to increases in voltage. This quick response minimizes the effect on electronic devices, enabling them to function properly even in potentially damaging environments, thereby improving the dependability of essential systems.

Two-Way Safeguarding

Varistors provide bidirectional safeguarding, making them ideal for diverse applications that may experience both positive and negative voltage surges. This feature enables them to efficiently protect against transient voltages in alternating current (AC) systems and direct current (DC) settings, ensuring thorough safety for various circuit configurations.

Reliability and Prolonged Durability

Featuring strong construction and great durability, varistors are built to endure multiple voltage transients for long durations. Their extended lifespan minimizes the necessity for regular replacements, leading to decreased maintenance expenses and offering continuous protection in challenging conditions.

Cost-Effective Option

Varistors offer a cost-effective option for surge protection while maintaining quality standards. Their simple installation and durability render them a budget-friendly option for manufacturers and engineers aiming to protect their products while staying within financial limits.

Flexibility in Design

Varistors are available in different shapes and sizes, allowing them to be customized for various circuit designs. This adaptability enables their incorporation into various applications, from consumer devices to industrial equipment, enhancing their usefulness in diverse environments.

Improved Circuit Efficiency

By effectively managing voltage spikes, varistors help enhance overall circuit performance. They assist in preserving stable operating conditions, which can result in enhanced efficiency, reduced power loss, and extended device lifespan.

Adherence to Industry Regulations

Numerous varistors are engineered to comply with strict industry standards, guaranteeing dependability and confidence in their functionality. This compliance instills confidence in engineers regarding their protection choices, assuring them that they are following safety and quality standards.

Drawbacks of Varistors

Although varistors provide many benefits, they also have their disadvantages. Being conscious of these limitations is crucial for making informed choices regarding surge protection options.

Restricted Time During Intense Energy Peaks

A major disadvantage of varistors is their restricted capacity to withstand high-energy surge incidents for prolonged durations. In cases of severe voltage surges, a varistor can deteriorate over time or sustain damage if the stress surpasses its specified limit. This constraint requires thorough assessment when choosing a varistor for essential applications, as confirming it is rated for possible surges in the specific setting is vital for dependable performance.

Heat Production During Functioning

Varistors may produce heat while functioning, particularly when they are suppressing voltage surges. The generation of heat may cause thermal stress on the component and surrounding circuitry, possibly impacting the overall reliability of the system. In high-frequency or high-energy surge situations, it's essential to manage heat dissipation through effective thermal management methods, like spacing, heat sinks, or ventilation integrated into the device design.

Criteria for Accurate Sizing

For optimal performance, varistors need to be correctly sized for the specific application they are safeguarding. Choosing a varistor with insufficient ratings can cause ineffective voltage clamping, whereas over-specifying could lead to additional expenses. Engineers need to meticulously determine the energy ratings, clamping voltage, and usage conditions to guarantee that the varistor can effectively withstand expected surge occurrences. Inadequate sizing can undermine the device's protective features and impair circuit safety.

Possibility of Aging and Deterioration

As time passes, varistors may undergo aging and deterioration as a result of ongoing exposure to voltage transients. Their materials could deteriorate, potentially resulting in a decrease in their protective effectiveness. Ongoing testing and evaluation are essential to guarantee the effective operation of varistors in situations that demand reliable surge protection. It is also recommended to incorporate monitoring systems that can notify operators of possible failures or the necessity for replacements.

How to Test a Varistor?

The examination of a varistor is an important procedure carried out for several purposes. A key motivation is to maintain standards and comply with specifications, especially in the production stage. Moreover, testing is crucial when issues are raised about the varistor's performance or dependability. Regular assessments are essential for recognizing and resolving potential issues before they develop into larger problems.

The steps are shown below:

1. Unplugging from the Outlet for Varistor Examination

The first step in testing a varistor is to unplug it from the receptacle. This safety measure is meant to avoid unintentional shocks and guarantees that the device remains off while testing is conducted. After opening the outlet cover, find the varistor on the circuit board. It is essential to determine which part of the device is attached to the ground and which part is connected to the live wire. To reduce possible confusion, think about marking each side of the varistor prior to unplugging it from the outlet.

2. Removing and Unsoldering Varistor Leads

Locate the wire connections on both sides of the device, then go ahead and disconnect and desolder the varistor's lead. Utilize a soldering iron along with solder for this job. Exercise care while disconnecting and desoldering, since the leads can be tiny and fragile. If feasible, use a magnifying glass to improve clarity. Employ pliers to gently detach the lead, making sure to avoid any harm. After the leads have been effectively disconnected and desoldered, put them aside for later use, and then continue to take out the varistor from its place. Now that the varistor is detached from the outlet, the following step is to assess its performance.

3. Employing a Multimeter to Examine the Varistor

A multimeter, intended for assessing electrical characteristics such as voltage, current, and resistance, measures resistance in ohms (Ω). When evaluating a varistor, make sure the multimeter is adjusted to the proper range, usually according to the nominal resistance value you plan to assess.

To evaluate the varistor, attach one multimeter probe to each terminal, making sure both probes are linked to the same side of the component (for instance, ground and live wire). A measurement on the multimeter shows that the device is working and permitting current. Nevertheless, analyze the result cautiously; a low-resistance measurement might suggest functionality but could also indicate a defect. Implement suitable actions to resolve the problem.

If the multimeter shows no reading, it indicates that the device is not working and not allowing current to flow, implying possible damage or breakdown. Once you finish the varistor test, reattach it to the outlet cover and firmly secure the circuit board. Reattach and weld the leads properly to reduce the chance of unexpected shocks.

If the varistor is determined to be defective, timely replacement is essential. A faulty varistor creates a safety risk and can cause damage to your electrical system.

Principles of Varistor Selection

1. The choice of the voltage V1mA that is sensitive to pressure

Based on the chosen power supply voltage, the voltage applied continuously across the varistor's terminals must not exceed the "maximum continuous working voltage" value specified in the documentation. In other words, the maximum DC operating voltage of the varistor should exceed the DC working voltage of the power line (signal line) VIN, meaning VDC ≥ VIN; for a 220V AC power supply, it is essential to consider the variations in grid operating voltage, ensuring that the varistor's voltage rating is chosen with sufficient margin. The typical variation range of the national power grid is 25%. A varistor rated between 470V and 620V ought to be chosen as a more appropriate voltage-sensitive resistor. Opting for a higher voltage varistor can lower the failure rate and prolong the service life, although the residual voltage may increase slightly.

2. The choice of flow flux

The nominal discharge current of the varistor must exceed the necessary surge current or the highest surge current that could happen during the operation of the equipment. The nominal discharge current needs to be determined based on the number of surge life quotients from the pressure-sensitive resistor curve when exceeding the value more than 10 times, approximately 30% of the peak impact flux (i.e., around 0.3IP).

3. The choice of clamping voltage

The clamping voltage of the varistor should be lower than the highest voltage that the safeguarded component or device can tolerate (i.e. safety voltage).

4. The choice of capacitance Cp

For signals transmitted at high frequencies, the capacitance Cp needs to be lower, and conversely.

5. ResistanceMatch

The correlation between the internal resistance R of protected components (line) (where R ≥ 2Ω) and the varistor's transient internal resistance Rv is R ≥ 5Rv; for components featuring low internal resistance, to prevent affecting the signal transmission rate, it is recommended to use a varistor with high capacitance.

Real-World Applications of Varistors

Varistors are essential components in surge protection systems for multiple applications. Their capacity to absorb and dissipate excessive voltage spikes renders them essential in the following domains:

Surge Defense in Electrical Supply Systems

In power supply systems, varistors are used to safeguard delicate electronic parts from voltage surges. When the voltage surpasses a specific limit, the varistor conducts, thereby limiting the voltage to a safe range and protecting the power supply and attached devices from damage.

Overvoltage Safeguarding in Electronic Equipment

Electronic devices can be susceptible to overvoltage situations triggered by elements like electrical storms or abrupt power changes. Varistors are frequently utilized in these devices to control voltage levels, guaranteeing they function safely within their designated thresholds. This safeguard increases the durability of electronic devices and improves their dependability.

Lightning Protection Arresters

Lightning strikes can produce intense surges that lead to significant harm to electrical systems. Varistors are key elements in lightning surge protectors, offering a crucial line of defense. They respond promptly to steer the influx away from delicate machinery, reducing the chances of disastrous breakdowns.

Motor Control and Drive Systems

In motor control applications, voltage surges may occur during operation, particularly in systems that use inductive loads. Integrating varistors into motor drive circuits defends against these transient voltages, promoting seamless performance and protecting the motor and control systems.

Telecom Devices

Telecommunication systems are always vulnerable to voltage transients. Varistors are commonly utilized in telecommunications devices to safeguard against surges that may interfere with communication lines and harm delicate electronics. Their rapid response time aids in preserving stability within communication networks.

Vehicle Electronics

As automotive electronic systems become increasingly complex, the demand for effective surge protection is essential. Varistors are used in multiple automotive applications, protecting against voltage surges from external elements like road conditions and environmental influences. This safeguard is essential for the durability and security of contemporary vehicles.

Conclusion

In conclusion, the symbol of varistor signifies more than merely a component; it embodies an essential role in safeguarding electrical circuits from voltage spikes. Grasping its importance can result in improved design decisions and increased circuit reliability. Varistors are essential for safeguarding electronic circuits against voltage spikes by creating a low-resistance pathway during overvoltage situations, thus averting harm to sensitive components.Firms such as Unikey offer not only top-notch varistors and various electronic parts, but they also assist their clients with attractive pricing, outstanding service, and innovation resources. By utilizing these advantages, both experienced engineers and enthusiasts can guarantee that their projects succeed while maintaining safety and efficiency in their designs.

Recommended Reading: