A Comprehensive Guide to Electrical Terminal Connectors

electrical terminal connectors are critical components in electrical and electronic systems, facilitating secure and efficient connections between wires and devices. This article delves into the fundamentals of terminal connectors, their types, selection criteria, installation and maintenance, practical applications, technological advancements, and safety standards.

1. Understanding Electrical Terminal Connectors

Definition and Purpose

Electrical terminal connectors are devices designed to connect or terminate a single wire or multiple wires, ensuring a continuous and stable electrical connection. They play a critical role in maintaining the integrity of electrical circuits by providing a safe and reliable connection point. These connectors are used in a wide range of applications, from household appliances and automotive systems to industrial machinery and complex electronic devices.

Types and ClassificationsThere are various types of terminal connectors, each serving specific purposes:Ring Terminals:Design: Ring-shaped connection point that fits over a stud or bolt.Usage: Provides a permanent and secure connection. Commonly used in automotive and industrial applications where a robust connection is needed.Advantages: Secure and reliable, easy to inspect visually.

Spade Terminals (Fork Terminals):Design: Fork-shaped connection point that slides under a screw or bolt.Usage: Allows for quick and easy connection and disconnection. Ideal for situations where frequent maintenance or replacement is required.Advantages: Easy to install and remove, versatile for various applications.

Quick Disconnects:Design: Consists of male and female connectors that snap together.Usage: Enables rapid connection and disconnection without the need for tools. Widely used in consumer electronics and appliances.Advantages: Convenient for frequent disconnections, available in insulated and non-insulated versions.

Butt Connectors:Design: Cylindrical shape that joins two wires end-to-end.Usage: Commonly used for splicing wires together. Provides a secure and insulated connection.Advantages: Simple and effective for wire splicing, available in heat-shrink versions for added protection.

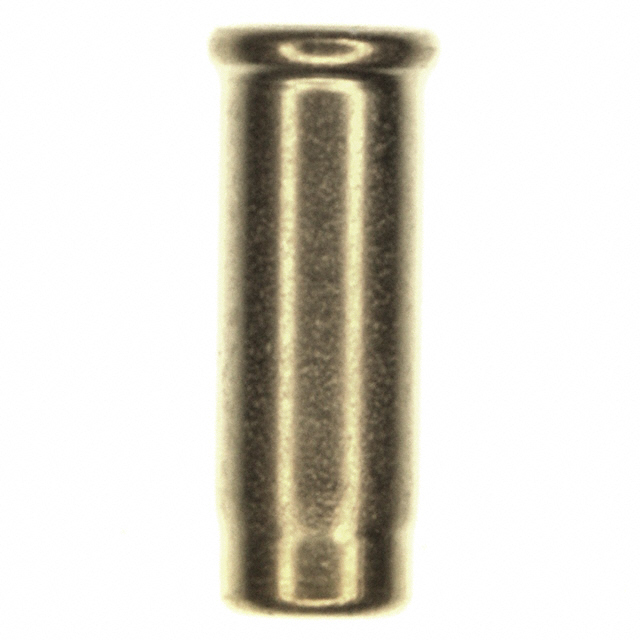

Bullet Connectors:Design: Cylindrical male and female connectors that snap together.Usage: Used for creating secure, inline connections. Often found in automotive and marine applications.Advantages: Easy to connect and disconnect, provides a reliable connection.

Pin Terminals:Design: Pin-shaped terminal that fits into a socket or connector.Usage: Used for connecting to terminal blocks or screw terminals. Suitable for applications requiring a neat and organized connection.Advantages: Provides a tidy connection, easy to insert and remove.

Specialty Terminal Connectors:Insulated Terminals: Provide additional protection against electrical shock and short circuits. Ideal for applications where safety is a concern.Heat-Shrink Terminals: Feature a heat-shrinkable sleeve that, when heated, shrinks to provide a secure, insulated, and sealed connection. Perfect for use in harsh environments or where moisture protection is needed.

2. Choosing the Right Terminal Connector

Selecting the appropriate electrical terminal connector is crucial for ensuring the reliability and safety of electrical connections. This section explores the key factors to consider, including material selection, specifications and standards, as well as brand and pricing considerations.

Material SelectionThe material of a terminal connector greatly influences its performance, durability, and suitability for specific applications. Common materials used for terminal connectors include:Copper:Properties: Excellent electrical conductivity, good thermal conductivity, and corrosion resistance.Applications: Widely used in general electrical applications due to its superior conductivity and reliability.Advantages: High conductivity reduces energy loss, easy to crimp, and durable.

Aluminum:Properties: Lightweight, lower cost compared to copper, and moderate conductivity.Applications: Used in large-scale power distribution and where weight is a concern.Advantages: Cost-effective for high-volume applications, lightweight, and resistant to oxidation when properly treated.

Stainless Steel:Properties: High tensile strength, corrosion resistance, and moderate conductivity.Applications: Suitable for harsh environments, including marine and industrial applications.Advantages: Excellent durability and corrosion resistance, ideal for applications exposed to moisture or chemicals.

Brass:Properties: Good electrical conductivity, corrosion resistance, and mechanical strength.Applications: Used in automotive, industrial, and electronic applications.Advantages: Provides a good balance of conductivity, strength, and corrosion resistance.Specifications and Standards

Selecting the right terminal connector involves considering the wire gauge, current load, and environmental factors. Adhering to standards such as those from the International Electrotechnical Commission (IEC) or Underwriters Laboratories (UL) ensures reliability and safety.

Compliance with StandardsCompliance with international standards, such as those from the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL), ensures that terminal connectors meet established safety and performance criteria. Key standards include:IEC Standards: Govern the safety, performance, and testing methods for electrical components, ensuring they meet global safety requirements.

UL Standards: Provide certification for electrical products, indicating they have been tested and meet specific safety standards.

Reputable Brands:TE CONNECTIVITY: Known for a wide range of high-quality connectors suitable for various applications.MOLEX: Offers reliable connectors with a strong focus on innovation and technology.PANDUIT: Provides durable and efficient connectors, often used in industrial and commercial applications.unikeyic Electronics, as a distributor of terminal connectors, offers a wide range of connectors from multiple renowned brands including TE Connectivity, Molex, and Panduit. Our extensive inventory ensures that we can meet diverse connectivity needs across various applications. Whether you are looking for high-performance solutions or cost-effective options, Unikeyic Electronics provides reliable products that adhere to industry standards and specifications.

3. Installation and Maintenance of Terminal Connectors

Proper installation and maintenance of terminal connectors are crucial for ensuring their long-term reliability and performance. This section provides a detailed guide on installation steps, common issues and solutions, and maintenance tips to keep terminal connectors functioning optimally.

Common Issues and Solutions1. Loose Connections:Issue: The wire can easily pull out from the connector.Solution: Ensure the correct size terminal for the wire gauge and apply sufficient crimping force. Double-check the crimp for security.

2. Corrosion:Issue: Corrosion at the connection point can lead to poor conductivity and failure.Solution: Use connectors made of corrosion-resistant materials, such as tin-plated copper or stainless steel. Apply dielectric grease to protect against moisture.

3. Overheating:Issue: The connector becomes hot to the touch, indicating a poor connection or excessive current load.Solution: Verify that the terminal connector is rated for the current load. Ensure a tight and secure crimp to minimize resistance. If necessary, upgrade to a higher-rated connector.

4. Frayed Wires:Issue: Strands of the wire are frayed or not properly seated in the connector.

Solution: Ensure all strands are twisted together before insertion. Use a terminal with an appropriate barrel size to accommodate the wire.

Maintenance Tips1. Periodic Inspection:Procedure: Regularly inspect terminal connections for signs of wear, corrosion, or damage.Tip: Schedule inspections based on the operating environment and application demands.

2. Cleaning:Procedure: Clean terminal connectors using a contact cleaner or isopropyl alcohol to remove dirt and oxidation.Tip: Use a soft brush to gently clean the connector without damaging it.

3. Re-Crimping:Procedure: If a connection appears loose or unreliable, cut the old connector off, strip the wire again, and apply a new terminal connector.Tip: Use a high-quality crimping tool to ensure a reliable connection.

4. Protective Measures:Procedure: Apply dielectric grease to connectors to prevent moisture ingress and corrosion, especially in harsh environments.Tip: Use heat-shrink tubing or insulated terminals to provide additional protection.

5. Replacement:Procedure: Replace any worn or damaged terminal connectors promptly to maintain system integrity and performance.

Tip: Keep a stock of commonly used terminal connectors for quick replacements during maintenance.

4. Practical Applications of Terminal Connectors

Electrical terminal connectors play a vital role in a wide range of applications, providing reliable connections that are essential for the functionality of various systems and devices. This section explores how terminal connectors are used in household appliances, industrial equipment, and the automotive industry, highlighting their importance in each context.Household AppliancesIn household appliances, terminal connectors are crucial for ensuring safe and efficient operation. They are used to connect various electrical components within the appliances, allowing for the proper flow of electricity.

Refrigerators and Freezers Components: Connectors are used to join the compressor, thermostat, and defrost heaters.

Washing Machines and Dryers Components: Motor connections, heating elements, and control panels.

Microwave Ovens Components: Magnetron, turntable motor, and control circuits.

Dishwashers Components: Pump motors, heating elements, and control boards.

HVAC Systems Components: Thermostats, compressors, and fans.

Industrial EquipmentIn industrial settings, terminal connectors are used in control systems, machinery, and automation equipment. They provide the robust connections needed to handle high currents and harsh environments.

Control Panels Components: Sensors, relays, and programmable logic controllers (PLCs).

Motor Connections Components: Electric motors, drives, and starters.

Industrial Automation Components: Robots, conveyor systems, and assembly lines.

Power Distribution Components: Busbars, transformers, and switchgear.Automotive IndustryIn the automotive industry, terminal connectors are essential for the electrical systems that power modern vehicles. They are used to connect everything from basic lighting systems to advanced electronic controls.

Lighting Systems Components: Headlights, taillights, and interior lighting.

Engine and Powertrain Components: Ignition systems, sensors, and fuel injectors.

Infotainment Systems Components: Audio systems, navigation, and displays.

Safety Systems Components: Airbags, anti-lock braking systems (ABS), and electronic stability control (ESC).

Electric and Hybrid Vehicles Components: Battery connections, electric motors, and charging systems.

Conclusion

Electrical terminal connectors are indispensable in creating reliable and efficient electrical connections. By understanding their types, selection criteria, installation practices, practical applications, users can make informed decisions and ensure the optimal performance of their electrical systems.Electrical terminal connectors are indispensable in various applications across household appliances, industrial equipment, and the automotive industry. Their ability to provide secure, reliable, and efficient electrical connections is crucial for the performance, safety, and longevity of these systems. By understanding the specific applications and requirements of terminal connectors, users can ensure optimal connectivity in their respective fields.When selecting terminal connectors, it's essential to choose products from reputable brands to ensure quality and reliability. Unikeyic Electronics, a global leader in terminal connector products, offers a wide range of high-quality connectors that meet international standards and cater to various industry needs. With Unikeyic Electronics' extensive product portfolio, you can find the right electrical terminal connectors for your specific application, ensuring optimal performance and safety.