Hysteresis in Electronics: Why It Matters and How It's Used

Introduction to Hysteresis Phenomena

Hysteresis is a fundamental physical phenomenon observed across multiple disciplines, from materials science to electronic engineering. At its core, it describes a system's dependence not only on its current inputs but also on its historical states, creating a characteristic "memory effect."

This behavior manifests as a lag between input and output, forming distinctive hysteresis loops when plotted graphically. In magnetic materials, hysteresis appears as the persistence of magnetization after removing an external field, while in electronic circuits, it enables noise immunity and stable switching.

The understanding of hysteresis is crucial for designing reliable systems—whether optimizing energy efficiency in transformers, improving touchscreen responsiveness, or enhancing control systems in smart devices. Its unique ability to filter noise while maintaining state predictability makes hysteresis an indispensable concept in both theoretical research and practical engineering applications.

Fundamental Principles of Hysteresis

Magnetic and Electrical Hysteresis

Magnetic hysteresis primarily manifests in two forms: magnetic hysteresis in ferromagnetic materials (such as silicon steel) and electrical hysteresis observed in electronic circuits. Magnetic hysteresis occurs when magnetic domains in a material remain aligned even after the external magnetic field is removed, resulting in residual magnetism. This effect forms the familiar hysteresis loop when plotting the relationship between magnetic flux density and magnetic field strength.

Similarly, hysteresis in coils carrying current and in electronic circuits exhibits similar memory characteristics. The hysteresis curve of an electrical system typically shows the relationship between input voltage and current, with the loop shape indicating energy losses occurring during rapid cycling. These energy losses are one of the key factors to consider when designing efficient electrical machines and electronic devices, and they are professionally referred to as hysteresis losses.

Rate-Dependent vs. Rate-Independent Hysteresis

Hysteresis behavior can be classified into two types: rate-dependent and rate-independent. Rate-independent hysteresis is commonly found in permanent magnets and many ferroelectric materials, where the shape of the hysteresis loop is unaffected by the rate of change of the input signal. In contrast, rate-dependent hysteresis is often observed in mechanical hysteresis systems or certain magnetic devices, where the shape of the hysteresis loop changes depending on the rate at which the input signal decays or switches.

This distinction is particularly important when designing systems requiring rapid switching or systems processing real-world signals (frequency changes). The adjustable hysteresis characteristics commonly found in modern electronic components enable engineers to select and optimize these characteristics to meet the specific requirements of a given application.

Hysteresis in Electronic Circuits

Hysteresis in Power Electronics

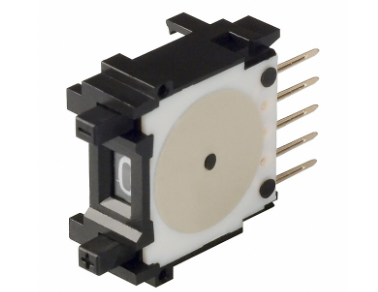

Power electronic systems widely utilize the principle of hysteresis, particularly in switches and motor control circuits. The hysteresis switch function in these applications helps to minimize additional losses caused by rapid switching while maintaining precise control over current.

Key applications include:

Voltage regulators with adjustable hysteresis bands

Motor controllers that prevent rapid cycling

DC-AC Inverters optimized for power efficiency

Protection circuits with release-dependent characteristics

A common example is the “smart temperature control” feature often advertised in recent years for home air conditioners. The core principle behind this is hysteresis: when the set temperature is 26°C, cooling actually starts at 24°C and stops at 28°C (creating a 4°C hysteresis window), avoiding frequent compressor startups and shutdowns. This extends compressor lifespan, saves electricity costs, and maintains a constant temperature range indoors.

In these systems, the ratio of magnetic flux density to magnetic field strength typically determines the optimal hysteresis setting, so it is essential to carefully consider the electrical and physical characteristics of the components involved.

Measurement and Characterization

Measurement and Characterization

Analyzing Hysteresis Loops

The primary tool for understanding hysteresis phenomena in electronics is analyzing hysteresis loops, whether magnetic or electrical. For magnetic materials, this involves plotting the relationship between magnetic flux (or magnetic flux lines) and magnetic field strength to reveal key parameters such as hysteresis loss.

Similarly, the electronic hysteresis loop shows the relationship between the input signal and the output response, demonstrating the unique memory effect that defines hysteresis behavior. Advanced measurement techniques such as magnetograms (magnetic flux line diagrams) can visually represent these effects in complex systems.

Quantifying Hysteresis Effects

Several key indicators are often used in electronics to represent hysteresis performance. For example, the input range between switching thresholds is called the hysteresis range, and the maximum deviation between the rising path and the falling path is called the hysteresis error.

These measurement indicators are particularly important when using precision pressure transmitters, electronic pressure transmitters, and other precision measurement equipment, as hysteresis effects can have a significant impact on product performance.

Practical Applications of Hysteresis Across Industries

Consumer Electronics Applications

Hysteresis principle is widely used in modern consumer electronics. In addition to the examples mentioned above, touch screens use narrow lag to distinguish between intentional and unintentional touches, and audio equipment also uses the principle of lag to achieve noise reduction and improve the user experience.

Industrial and Automotive Systems

Industrial applications leverage hysteresis for:

● Stable process control (avoiding rapid cycling),which we mentioned before.

● Reliable sensor interfaces (rejecting environmental noise)

● Robust switching systems (preventing chatter)

In automotive systems, hysteresis contributes to:

● Accurate fuel level indicators (despite sloshing)

● Consistent brake pedal response (withstanding vibration)

● Reliable engine control (filtering transient signals)

Design Considerations and Optimization

Material Selection

The category of materials directly determines the final hysteresis performance, making this aspect particularly crucial to focus on. Primarily, magnetic materials such as silicon steel are suitable for magnetic circuits, while ferroelectric materials are appropriate for specific electronic components. To achieve minimal hysteresis loss, continuous optimization of core materials must be pursued.

System-Level Optimization

The interrelationship between electrical, magnetic, and mechanical hysteresis effects in a system is complex. To efficiently utilize hysteresis characteristics, it is often necessary to consider multiple factors comprehensively, such as balancing the hysteresis range with the system response speed, minimizing additional losses while maintaining stability, optimizing for specific conditions, and considering temperature and aging effects.

Challenges and Future Directions

Current Limitations

While hysteresis effects offer significant advantages, they still present notable challenges that require further resolution. In precision measurement systems, hysteresis-induced errors can compromise accuracy, while complex magnetic circuits often suffer from substantial energy dissipation.

The intricate modeling requirements continue to pose implementation difficulties, compounded by the occasional emergence of anomalous hysteresis under specific operating conditions. These persistent issues demand ongoing investigation and innovative solutions.

Ongoing Research Areas

Current research endeavors are progressively expanding our comprehension and application of hysteresis phenomena. Scientists are focusing on developing novel materials with reduced hysteresis losses, creating advanced switching mechanisms with improved hysteresis characteristics, and refining modeling methodologies. Particularly promising are explorations into quantum-scale and molecular-level hysteresis behaviors.

These concerted efforts are not only deepening our fundamental understanding of electronic hysteresis but are also paving the way for more efficient and practical applications that will enhance various aspects of modern life.

Conclusion: The Enduring Importance of Hysteresis

From its fundamental manifestations in magnetic domains and ferromagnetic materials to its sophisticated implementations in modern electronic circuits, hysteresis remains one of the most versatile and valuable phenomena in electrical engineering.

Understanding what hysteresis in electronics is provides engineers with powerful tools for solving real-world design challenges across countless applications.

As technology advances, the principles of hysteresis continue finding new applications while maintaining their importance in traditional systems.

Ultimately, hysteresis represents a perfect example of how deep understanding of fundamental physical properties leads to practical engineering solutions. From the iron particles in primitive magnetic devices to the complex ferroelectric hysteresis loops in modern components, this phenomenon continues to shape the development of electronic systems across all fields of science and technology.