Choosing the Right Capacitor: Tantalum vs Ceramic

Picture yourself as an electronics engineer responsible for creating a small power supply for an innovative portable device. You require a capacitor capable of managing high capacitance values while accommodating a confined area. You are at a dilemma: will you select tantalum capacitors for their dependability and stability, or will you go for ceramic capacitors recognized for their affordability and compactness? Considering factors such as voltage ratings, temperature stability, and application needs, the choice is essential. Learning that tantalum and ceramic capacitors are both essential components, choosing the right capacitor becomes a crucial task.

What are Tantalum Capacitors?

Definition

A tantalum electrolytic capacitor is a common type of electrolytic capacitor, which serves as a passive element in electronic circuits. It includes a pellet made of porous tantalum metal acting as an anode, coated with an insulating oxide layer that constitutes the dielectric, encased by liquid or solid electrolyte serving as a cathode. The tantalum capacitor, due to its extremely thin and comparatively high permittivity dielectric layer, sets itself apart from other typical and electrolytic capacitors by offering high capacitance per volume (high volumetric efficiency) and reduced weight.

Tantalum capacitors are naturally polarized devices. Applying reverse voltage may damage the capacitor. Non-polar or bipolar tantalum capacitors are created by effectively linking two polarized capacitors in series, with their anodes facing in opposite orientations.

Tantalum electrolytic capacitors are widely utilized in electronic devices that demand consistent capacitance, minimal current leakage, and where dependability is essential. Owing to its reliability, longevity, and performance in harsh environments, it is employed in medical devices, aerospace, and military sectors. Additional applications encompass power supply units, measurement devices, telecommunications gear, and computer accessories.

Construction

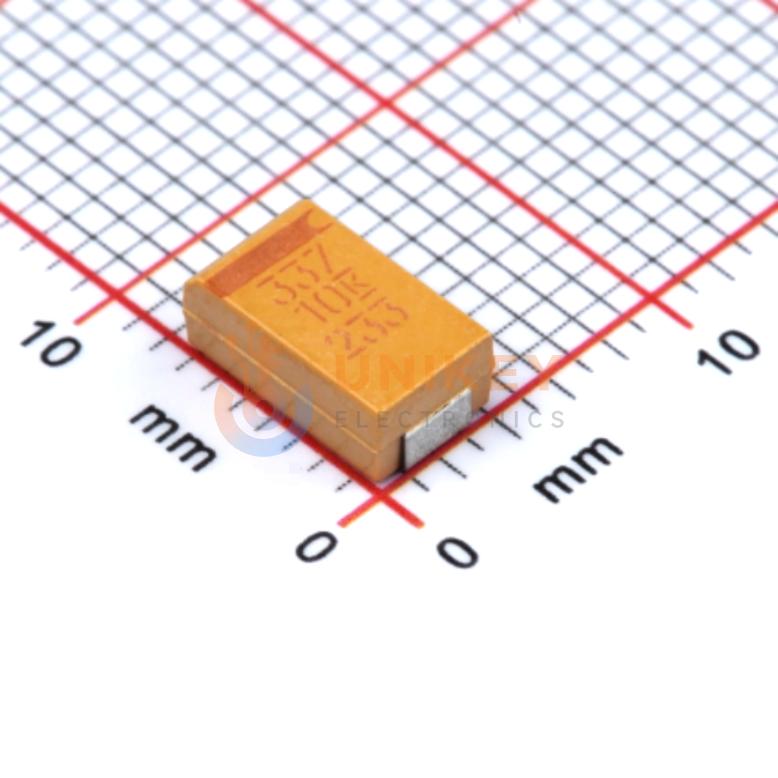

Tantalum is a lustrous, silver-gray metal. When examining the cross-sectional perspective of a tantalum capacitor, such as the typical SMD tantalum electrolytic chip capacitor featuring a solid electrolyte shown in Figure 4, it consists of tantalum powder that has been compressed and sintered into a pellet functioning as the positive (anode) terminal of the chip capacitor. The positive (anode) terminal is covered by a protective oxide layer that forms the dielectric, while the solid manganese dioxide electrolyte acts as the negative (cathode) terminal.

Tantalum capacitors provide significant capacitance relative to their size and weight because of their thin and relatively high permittivity dielectric layer, distinguishing them from other electrolytic capacitors. As a result, the significant capacitance of tantalum electrolytic capacitors makes them suitable for transmitting or bypassing low-frequency signals, in addition to storing large amounts of electrical energy.

Advantages

Compact in Dimensions

Tantalum capacitors attain a high capacitance per unit volume due to their use of tantalum powder containing very fine particles, and the dielectric constant of tantalum oxide film being 17 times greater than that of aluminum oxide film.

Broad Temperature Operating Range

Typically, tantalum electrolytic capacitors can function properly within a temperature range of -50°C to 100°C. While aluminum electrolytic capacitors can operate in this spectrum as well, their electrical performance is considerably lower than that of tantalum electrolytic capacitors.

Extended Service Lifespan, Elevated Insulation Resistance, Minimal Leakage Current

The tantalum oxide film in the tantalum electrolytic capacitor is not only corrosion-resistant but also capable of sustaining excellent performance over an extended period.

Favorable Impedance Frequency Traits

For capacitors that have inadequate frequency characteristics, the capacitance greatly diminishes at high operating frequencies, and the loss also rises considerably. However, solid tantalum electrolytic capacitors are capable of operating above 50kHz. As the frequency increases, tantalum capacitors will exhibit a decrease in capacity, although this reduction is quite minimal.

Data indicates that at a frequency of 10kHz, the capacitance of tantalum capacitors decreases by under 20%, whereas the capacitance of aluminum electrolytic capacitors can reduce by up to 40%.

High Dependability

Tantalum oxide film exhibits stable chemical characteristics, and since Ta2O5, the substrate for the tantalum anode, can endure strong acids and bases. Thus, it can utilize solid electrolytes or liquid electrolytes with low acid resistance, resulting in lower losses for tantalum electrolytic capacitors compared to aluminum electrolytic capacitors, with good temperature stability.

What are Ceramic Capacitors?

The introduction of ceramic capacitors can be found Ceramic Capacitors for type. They are general-purpose capacitors, excellent for high-frequency applications.

Main Ceramic Capacitors Types

Semiconductor Ceramic Capacitors

Microminiaturization of capacitors refers to the design of capacitors that, while occupying the least volume, achieve the highest possible capacity, representing one of the trends in capacitor development. To separate capacitor components, there are two fundamental methods for miniaturization, assuming the dielectric material has a very high dielectric constant and the thickness of the dielectric layer is minimized as much as possible.

Among ceramic materials, ferroelectric ceramics possess a high dielectric constant; however, achieving a minimal thickness in the ceramic dielectric is challenging when fabricating standard ferroelectric ceramic capacitors using ferroelectric ceramics. To begin with, due to the low strength of ferroelectric ceramics, they tend to break easily when made thin, complicating practical production operations. Additionally, when the ceramic dielectric is extremely thin, it is prone to various structural defects, making the manufacturing process quite challenging.

Surface layer ceramic capacitors employ a thin insulating layer created on the surface of semiconductor ceramics like BaTiO3, which serves as the dielectric layer. The semiconductor ceramics can be viewed as a series circuit of the dielectric itself. The thickness of the insulating surface layer of ceramic capacitors varies from 0.01 to 100 μm based on the method of formation and the conditions used.

Grain Boundary Layer Ceramic Capacitors

The surface of BaTiO3 semiconductor ceramics, featuring fully developed grains, is covered with suitable metal oxides and subjected to heat treatment under oxidation conditions at an appropriate temperature. A thin insulating layer of solid solution is created along the grain boundaries. This thin solid-solution insulating layer exhibits high resistivity, and while the ceramic grain interior remains a semiconductor, the complete ceramic structure acts as an insulating medium with an observed dielectric constant as elevated as 2*104 to 8*104. The capacitor made with this porcelain is known as a grain boundary layer ceramic capacitor, abbreviated as a BL capacitor.

High-voltage Ceramic Capacitor

As the electronics industry rapidly evolves, there is a pressing requirement to create high-voltage ceramic capacitors that feature high breakdown voltage, minimal loss, compact size, and enhanced reliability. Over the past two decades, the high-voltage ceramic capacitors developed both domestically and internationally have found extensive applications in electric power systems, laser power supplies, tape recorders, color televisions, electronic microscopes, copiers, office automation equipment, aerospace, missiles, navigation, and more.

Ceramic materials based on barium titanate feature high dielectric coefficients and excellent AC voltage resistance, yet they also suffer from issues like changes in capacitance as dielectric temperature increases and a decrease in insulation resistance. The Curie temperature for strontium titanate crystal is -250℃, and at room temperature, it exhibits a cubic crystal system chalcogenide structure, characterized as paraelectric and lacking spontaneous polarization properties. The variation in dielectric constant of strontium titanate-based ceramic material is minor under high voltage, and the changes in tgδ and capacitance are minimal, which makes it highly advantageous as a dielectric for high voltage capacitors.

Multilayer Ceramic Capacitors (MLCC)

Multilayer ceramic capacitor is the most commonly used chip component, consisting of inner electrode material and ceramic layers arranged in parallel, which are then fired together to form a single unit, also referred to as chip monolithic capacitors. They feature a compact size, high specific capacitance, and excellent precision, allowing for installation on printed circuit boards (PCBs) and hybrid integrated circuits (HICs). This effectively minimizes the size and weight of electronic information terminal products, particularly portable ones, while enhancing product reliability. It aligns with the IT industry's trend toward miniaturization, lightweight design, high performance, and multifunctionality.

Advantages of Ceramic Capacitors

They are dependable and possess excellent frequency response features, even when functioning at elevated frequencies.

They are able to endure higher voltages reaching up to 100 volts.

They weigh less than other types of capacitors.

The price of these products is extremely inexpensive.

Wide variety of shapes and sizes are accessible.

Their ESR (effective series resistance) and ESL (effective series inductance) are lower than those of other capacitors.

Key Comparisons Between Tantalum and Ceramic Capacitors

Polarization Differences

Tantalum capacitors are generally polarized. This indicates that they can solely be linked to a DC power source while maintaining the proper terminal polarity. Ceramic capacitors, in contrast, are non-polar and can be safely linked to an AC power source. Ceramic capacitors exhibit superior frequency response due to their non-polarized nature.

Temperature Response Capabilities

Under temperature fluctuations, tantalum capacitors typically exhibit a linear change in capacitance, whereas ceramic capacitors generally display a non-linear response. Nevertheless, ceramic capacitors can be designed to behave linearly by limiting the operating temperature ranges and considering the temperature response in the design process.

Aging and Stability Factor

The metallic design of tantalum capacitors allows them to age longer and retain a greater level of stability compared to ceramic capacitors. A request for tantalum capacitors necessitates enduring performance.

In contrast to tantalum capacitors, ceramic capacitors possess a reduced lifespan. In addition, their temperatures often vary more regularly. Therefore, their superior performance renders them more appropriate for applications where instabilities are not an issue.

Voltage Response

When observing capacitance variations with applied voltage, tantalum capacitors exhibit steady stability, while ceramic capacitors do not. As the applied voltages increase, the permittivity of the dielectric decreases in the ceramic capacitor, resulting in alterations in capacitance. While the variations in capacitance of ceramic capacitors are typically linear and can be readily managed, certain higher permittivity dielectrics may experience a reduction of about 70% in their initial capacitance when functioning at rated voltage.

Tantalum vs Ceramic Capacitors in Applications

Suitable Use Cases for Tantalum Capacitors

Tantalum capacitors are well-known for their elevated capacitance values, small form factor, and dependability, which render them suitable for a wide range of applications. A key application of these capacitors is in filtering power supplies, as their capacity to manage high ripple currents guarantees consistent voltage levels in electronic circuits. They are frequently present in consumer electronics, networking equipment, and industrial machinery, where reliable performance is essential.

Furthermore, tantalum capacitors are ideal for applications in RF circuits, decoupling tasks, and timing circuits, primarily because of their reliable electrical characteristics. They demonstrate outstanding frequency response traits, rendering them ideal for high-frequency uses such as mobile phones and communication gadgets. Moreover, their sturdy design offers protection against moisture and corrosion, enabling them to function dependably in severe environmental situations, like automotive electronics.

Suitable Use Cases for Ceramic Capacitors

Conversely, ceramic capacitors are preferred due to their flexibility and wide range of capacitance choices. They are commonly utilized in applications that need non-polarized components, including AC coupling, bypassing, and decoupling in digital circuits. Due to their compact dimensions and affordability, they can be utilized in significant numbers on printed circuit boards (PCBs), making them a frequent selection for consumer electronics, such as audio devices and household appliances.

Ceramic capacitors also perform exceptionally well in scenarios where a high-frequency response is critical. Because of their flat capacitance in relation to voltage, they are frequently used in RF applications, high-speed digital devices, and audio filtering. Moreover, their stability at different temperatures renders them appropriate for automotive, aerospace, and medical devices that might encounter extreme conditions.

Nonetheless, it’s important to take into account the capacitance reduction in ceramic capacitors when voltage is applied, particularly in those with higher permittivity. In numerous instances, choosing a capacitor requires weighing voltage, temperature, and size constraints.

Sourcing and Reliability Considerations

When selecting capacitors for electronic applications, sourcing and reliability are paramount. The decision between tantalum and ceramic capacitors is influenced by several factors, including availability, performance consistency, and supplier trustworthiness.

Sourcing Tantalum Capacitors

Tantalum capacitors are well-known for their excellent performance and dependability; however, they present sourcing difficulties mainly because of the materials employed in their manufacturing. Tantalum is a scarce metal, mainly obtained from nations with restricted supply chains, like the Democratic Republic of Congo. This may result in variations in availability and costs, creating procurement difficulties for manufacturers.

Additionally, tantalum capacitors are vulnerable to specific failure mechanisms, such as thermal runaway if used beyond the designated voltage and temperature limits. This requires meticulous sourcing from trusted suppliers that follow rigorous quality control measures. Selecting suppliers that offer capacitors with dependable specifications and traceability is crucial for ensuring consistent performance in vital applications.

Sourcing Ceramic Capacitors

Conversely, ceramic capacitors provide a more readily available sourcing option since they are made from commonly accessible materials. The manufacturing of ceramic capacitors can typically be expanded, reducing their vulnerability to supply chain disruptions. This accessibility enables producers to react more adaptively to market needs without being as concerned about fluctuating costs.

Nevertheless, obtaining ceramic capacitors entails a specific range of factors to consider. Producers need to guarantee they acquire capacitors that fulfill particular performance standards, particularly in terms of voltage coefficients and thermal stability. Since these components are susceptible to "DC bias" effects that can lead to a notable decrease in capacitance when voltage is applied, it is essential to ensure that the sourced parts are appropriate for their intended uses.

Reliability Across Applications

Reliability plays a crucial role in both tantalum and ceramic capacitors, and grasping their behavior in different environments can significantly influence design decisions. Tantalum capacitors are recognized for their outstanding reliability in consistent operating conditions. Nonetheless, engineers need to stay mindful of their constraints and possible failure modes, particularly in high-stress settings. Choosing capacitors with suitable voltage ratings is essential for ensuring safe function and longevity.

At the same time, ceramic capacitors provide a strong option for various applications due to their natural resistance to moisture and temperature changes. Nevertheless, worries regarding their capacitance shifting with different voltage levels indicate that comprehensive performance validation against specific application criteria is essential.

To sum up, the choice between tantalum and ceramic capacitors is shaped by their electrical properties as well as sourcing flexibility and dependability. Producers need to reconcile material accessibility with performance requirements while making certain they collaborate with reliable suppliers. In this way, they can obtain dependable parts that improve the functionality and lifespan of electronic devices.

Cost Implications of Tantalum Capacitors

When evaluating the cost implications of tantalum capacitors, it’s important to consider several vital factors that influence their pricing and overall value. These include material availability, manufacturing processes, and their operational longevity, which can greatly affect both upfront and long-term costs.

Material Availability and Pricing Trends

Tantalum, an uncommon and valuable metal, serves as the foundation for tantalum capacitors. The restricted supply of tantalum, mainly obtained from a small number of areas globally, renders these capacitors more prone to fluctuations in cost. Variations in the cost of raw materials can result in higher production costs, which could subsequently be transferred to buyers. For manufacturers and designers dependent on tantalum capacitors, this may present a financial risk, particularly in cases where price consistency is crucial for budgeting and planning.

Manufacturing and Labor Costs

The production method for tantalum capacitors is more complex than that of ceramic capacitors. This intricacy necessitates improved technology, expert workforce, and, as a result, increased initial expenses related to manufacturing. However, the specialized nature of tantalum capacitors frequently warrants this elevated cost because of their exceptional performance in demanding applications.

Longevity and Performance

A prominent characteristic of tantalum capacitors is their dependability and extended lifespan in comparison to various other types. Although the upfront expense might be greater, the ability of tantalum capacitors to endure challenging conditions and retain stable capacitance over their lifespan can ultimately result in savings over time. Reduced replacements and diminished failure rate can greatly lower maintenance expenses and downtime, rendering them appealing for high-frequency applications.

Application-Specific Considerations

The selection of tantalum capacitors is frequently determined by the needs of the application. For applications requiring high performance, where reliability and effectiveness are essential, investing in tantalum capacitors is often viewed as a valuable decision. Conversely, in situations where size and cost are crucial—like in consumer electronics—ceramic capacitors might be the more suitable option. Evaluating return on investment (ROI) according to performance metrics relevant to the intended use can aid in justifying the cost impacts linked to tantalum.

Conclusion

In the clash of tantalum and ceramic capacitors, the decision ultimately depends on the particular needs of the application. Tantalum capacitors are perfect for demanding, reliable applications because of their durable design and long lifespan, making them a valuable investment even with the steeper initial expenses. Their capacity to sustain stable capacitance when under stress can result in decreased operational risks and reduced maintenance costs over time. In contrast, ceramic capacitors are superior in situations where budget, dimensions, and expandability are crucial, particularly in consumer electronics. Although they tend to be cheaper and simpler to produce, they might not provide the same reliability in performance when faced with challenging conditions. Ultimately, an informed decision requires balancing performance advantages with cost factors and application requirements to find the most suitable option for both present and upcoming projects.