Working Principle of an Accelerometer: How Does It Work and Its Major Applications Across Various Industry Verticals

Definition of an Accelerometer

An accelerometer is a piezoelectric device for acceleration measurement. It detects changes in velocity or acceleration as a function of time in mostly one, two, or three dimensions of movement (X, Y, and Z axes). The instrument works by detecting the effects of various forces acting on a mass or sensor element in the accelerometer, and then converting those results into an electrical signal that can be measured and interpreted.

Purpose of an Accelerometer

An accelerometer's only goals are to precisely gauge acceleration and figure out variations in the rate of velocity. Through this minuscule process, the accelerometer is normally able to catch the dynamic forces acting upon it, as well as catch dynamic changes in position. The accelerometer accepts acceleration as a result of the sensor's displacement, due to force (the electrical conversion completes the measurement of acceleration).

Here's a more detailed breakdown of its main purposes:

● Measure Acceleration: Sense dynamic and static movement.

● Monitor Vibration: Monitor movement in machines and systems.

● Sense Orientation: Compensate for tilt or position changes.

● Improve Safety: Employed in airbags, ABS, and fall detection.

● Health Tracking: Track activity, sleep, and rehab status.

● Maintenance Alerts: Identify machinery problems early.

● User Experience: Support screen rotation and motion control.

Construction of an Accelerometer

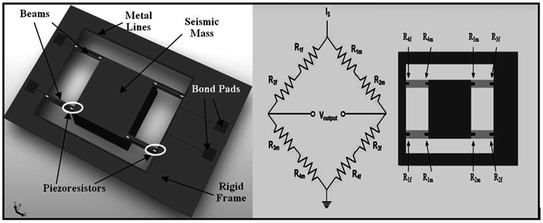

An accelerometer is a motion sensor that detects acceleration forces in more than one direction, usually with piezoelectric, MEMS, or capacitive technologies. Though diverse in design, the fundamental components collaborate to sense movement and transform it into an applicable output signal.

The key components that make up an accelerometer:

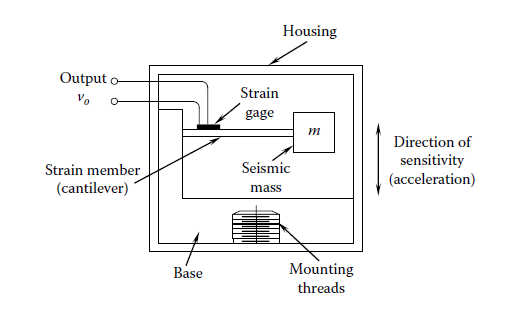

● Sensing Element (Proof Mass or Seismic Mass): Measures acceleration through motion with force.

● Suspension Mechanism: Allows for movement while supporting the mass.

● Sensing Mechanism: This converts the movement of the proof mass into an electrical signal (using capacitive, piezoelectric, etc. methods).

● Signal Processing Unit: Amplifies and shapes the output signal.

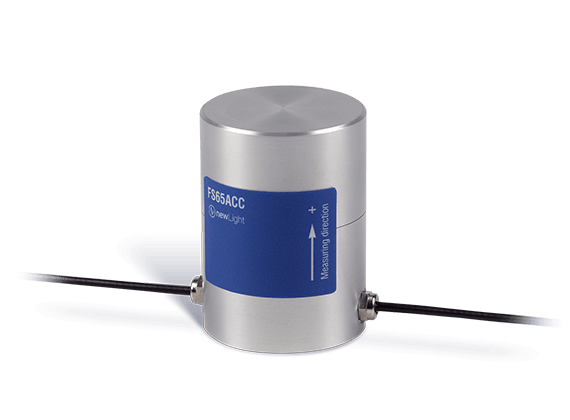

● Housing: This protects against environmental damage.

● Electrical Connections and Interface: Data transmission to external devices via analog or digital interfaces.

● Power Supply: Provides power to the sensor.

● Calibration and Compensation: Provides consistent and accurate readings.

Working Principle of an Accelerometer

The piezoelectric effect is responsible for making an accelerometer function. This enables accelerometers to measure the magnitude and direction of acceleration, which is crucial in applications such as motion tracking, orientation sensing, vibration analysis, and so on.

1. Inertial Mass and Acceleration

The principle is based on Newton's Second Law of Motion (F = m x a)

Where:

● F = Force exerted on the mass

● m = mass of the object

● a = acceleration.

Accelerometers are designed with various frameworks in mind, an inertial framework is one of those frameworks. When the inertial mass is subjected to an acceleration force, it will restrict the motion change, thereby causing it to shift in accordance with the accelerometer.

2. Transduction Mechanism

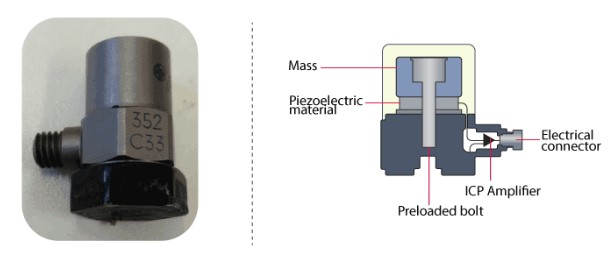

a. Capacitive Accelerometers (The Most Common Type)

● Mass and Electrodes: Fixed electrodes are matched to a movable proof mass.

● Capacitance Change: Motion changes the spacing of electrodes, affecting capacitance.

● Signal Conversion: Capacitance change is translated into acceleration data.

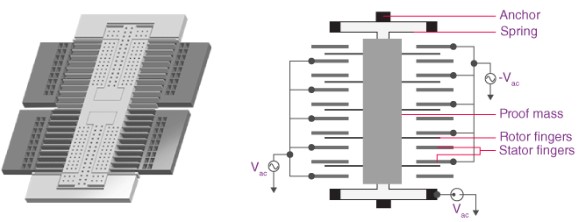

b. Piezoelectric Accelerometers

● Piezoelectric Material: Here, a piezoelectric material—one that generates an electrical charge when put under mechanical stress—is positioned around or beneath the proof mass.

● Force Measurement: When acceleration forces act on the mass, they compress or stretch the piezoelectric material, producing a charge that corresponds to the force (or acceleration).

● Signal Processing: The resulting charge is measured and converted into an electrical signal.

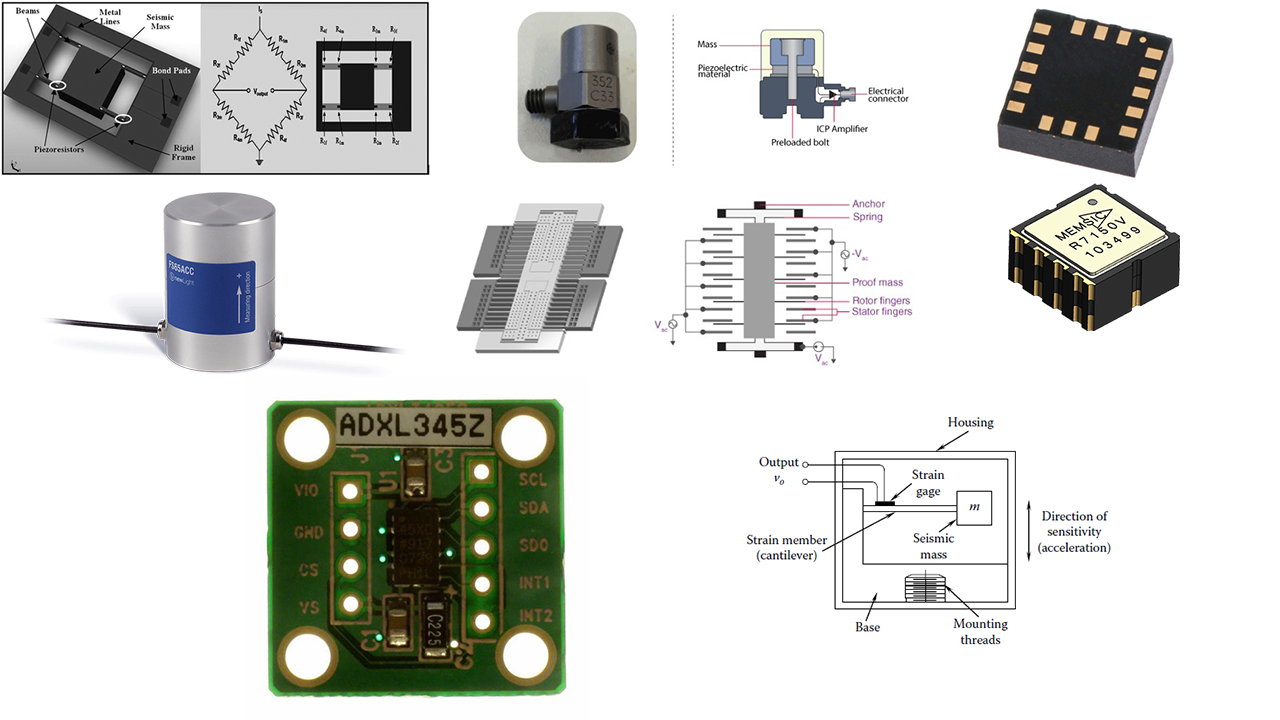

c. Piezoresistive Accelerometers

● Resistive Elements: Strain-sensitive resistors are positioned close to the proof mass.

● Strain Change: The moving mass due to acceleration strains the resistors and changes their resistance.

● Signal Output: Resistance variations are detected and converted into acceleration information.

d. Optical Accelerometers

● Optical Sensing: The motion of the proof mass is sensed through reflected light in sophisticated accelerometers.

● Light Variation: Varying reflected light shows displacement, which is employed to gauge acceleration

3. Multi-Axis Measurement

Typically, an accelerometer detects acceleration along 3D axes i.e., X, Y, and Z. This three-dimensional movement is the reason why accelerometers can be employed for applications such as detecting orientation, sensing motion, or analysing vibration.

● X-axis: Horizontal Axis Acceleration (moving from left to right direction).

● Y-axis: Vertical Axis Acceleration (upward and downward).

● Z-axis: Acceleration in the depth direction (forward and backward).

4. Signal Conditioning

The electrical signal from acceleration will usually undergo signal conditioning after it has been converted from acceleration into an electrical output:

● Signal Amplification.

● Filtering noise frequency to get rid of noise.

● Analog-to-Digital Conversion (ADC)-producing a digital signal suitable for processing by microcontrollers or other digital systems.

5. Output Signal

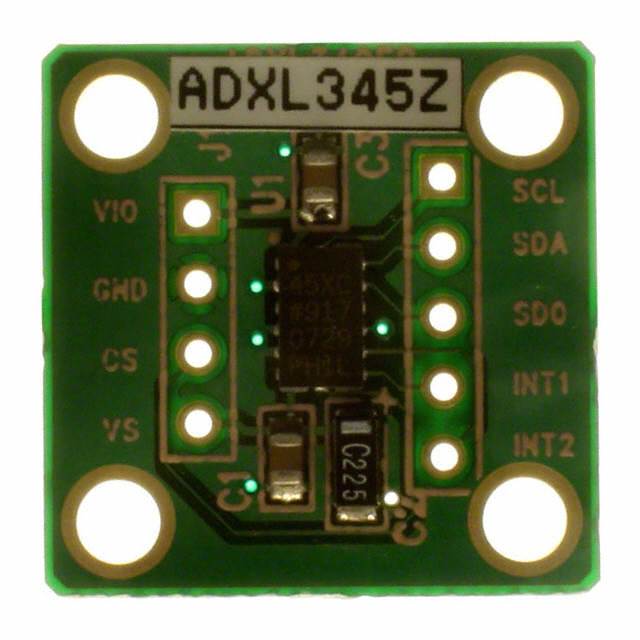

The output signal from the accelerometer will be in an analog (continuous voltage or current) or a digital (typically via I2C or SPI communication protocols) form. In both cases, the output signal from the accelerometer indicates acceleration applied along the X, Y, and Z axes in units of either g (gravitational force), or meters per second squared (m/s²).

Types of Accelerometers

There are many varieties of accelerometers, including their reliably performance mechanisms for detection of acceleration and different applications. The advantages of each type are based upon the required accuracy, environmental conditions and application.

● Capacitive Accelerometers: They measure changes in capacitance (the most commonly used in consumer electronics).

● Piezoelectric Accelerometers: Employ basic piezoelectric material to achieve charge when stressed.

● Piezoresistive Accelerometers: On the principle of piezoresistive effect, this accelerometer works on the principle of detecting the variation in resistance of a piezoresistive material (typically a thin film or a silicon strain gauge) due to mechanical strain applied to it.

● Optical Accelerometers: Optical accelerometers quantify displacement through the use of light, thus being ideal for high-accuracy applications.

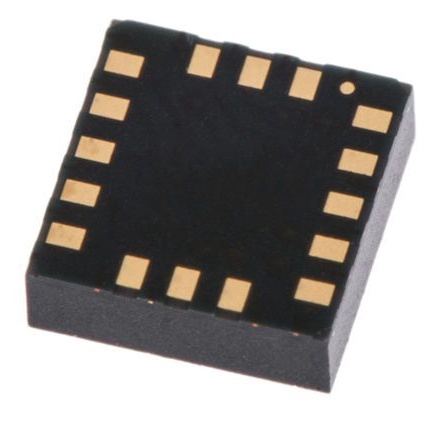

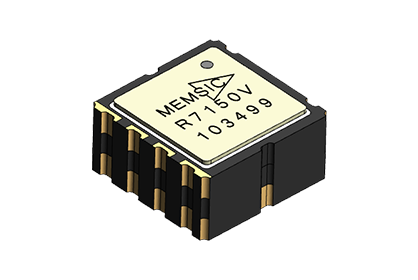

● MEMS Accelerometers: MEMS accelerometers are a form of micro-electromechanical system that incorporates micro-scale mechanical structures merged with electronic circuits to detect acceleration.

● Strain Gauge Accelerometers: Responsible for deformation measurement, etc.

● Digital Accelerometers: These offer direct digital output, making it easier to integrate them into digital systems.

● Thermal Accelerometers: Accelerometers that are responsive to acceleration using the effect movement has on the temperature distribution from the motion. The thermal accelerate relies on thermal physical principles to determine motion or acceleration instead of the more common mechanical, capacitive, and MEMS-based techniques.

Key Applications of Accelerometers

● Consumer electronics products like smartphones and fitness trackers.

● Automotive safety features such as airbags and anti-lock braking systems (ABS).

● Monitoring in industrial settings and structures, including machinery health and vibration analysis.

● Aerospace and Defence applications, for instance, inertial navigation and missile guidance.

● Healthcare uses, including fall detection and activity tracking.

● Sports and motion analysis.

● Robotics and automation, particularly in robot navigation and motion control.

● Environmental monitoring, such as detecting seismic activity.

● Entertainment can be experienced with cutting-edge gaming and virtual reality (VR).

These examples of the applications for accelerometers demonstrate advances in technology, improvement in safety, enhancement of performance, and improvements in user experience for a variety of industries.

unikeyic Electronics offers a wide range of accelerometers along with their datasheets, pricing details and other information as well.