What is a MAP Sensor?

Every time you start your car, a little device called the MAP (Manifold Absolute Pressure) sensor springs into action, working behind the scenes to keep your engine performing at its best. Whether you're dealing with a check engine light or just curious about how your vehicle works, understanding this critical component can save you time, money, and frustration. Modern vehicles rely on dozens of sensors, but the MAP sensor stands out as one of the most important for maintaining engine efficiency and performance.

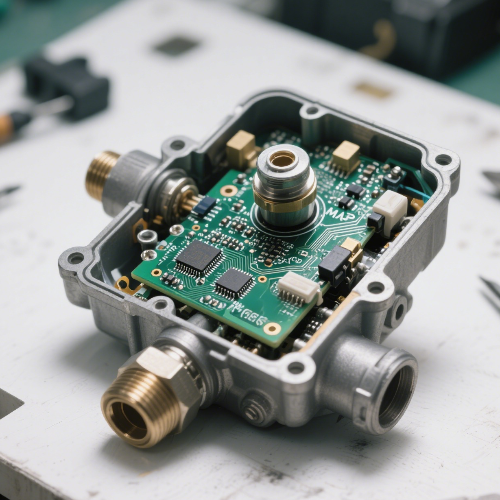

What Exactly is a MAP Sensor?

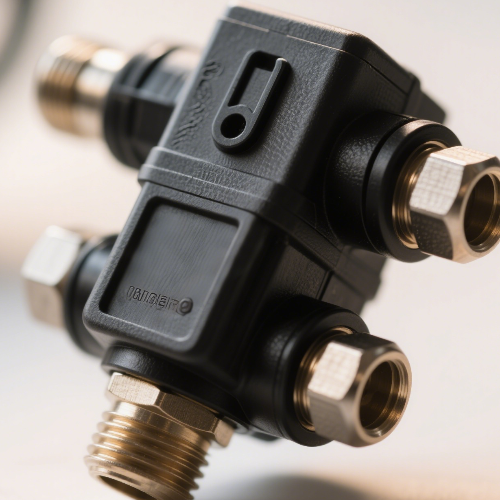

The MAP sensor is your engine's pressure gauge. Mounted on or near the intake manifold, this small but mighty device constantly measures the air pressure inside the manifold. It then sends this data to your vehicle's engine control unit (ECU) or powertrain control module (PCM) to help determine the optimal air-fuel mixture for current driving conditions. In fuel-injected engines, this information is crucial for calculating the precise amount of fuel needed for combustion.

Key Functions:

● Measures manifold pressure (both vacuum and boost) to determine engine load

● Helps calculate the mass of air entering the engine

● Works with other sensors like the MAF sensor to maintain proper air-fuel ratio

● Assists in ignition timing adjustments for optimum combustion

● Monitors boost pressure in turbocharged and supercharged engines

How MAP Sensors Work: The Technical Breakdown

Most modern MAP sensors are 3-wire devices that provide either a linear voltage signal or frequency signal to the ECU. The sensor's operation is fascinating when you break it down:

1.Pressure Detection: The sensor contains a diaphragm that flexes in response to pressure changes, comparing intake manifold pressure to atmospheric pressure. This pressure difference is what the ECU uses to determine engine vacuum or boost conditions.

2.Signal Generation: Inside the sensor, this mechanical movement gets converted to an electrical signal. Analog MAP sensors create a voltage output (typically 1-5 volts) proportional to pressure, while digital sensors use digital signal processing for more precise readings.

3.Data Transmission: The electrical signal travels through the wiring harness to the ECU. The signal wire carries this vital information while the other wires provide power (5-volt reference) and ground connection.

4.ECU Processing: The engine control module combines this data with inputs from other sensors (like the throttle position sensor and oxygen sensors) to make real-time adjustments to fuel injection and spark timing.

In turbocharged engines, the MAP sensor plays the additional critical role of monitoring boost pressure to prevent engine damage from over-boosting. It helps the ECU maintain safe pressure levels while still delivering optimal performance.

Common Symptoms of a Failing MAP Sensor

When this critical component starts failing, your car will usually give you plenty of warning signs. Being able to recognize these symptoms early can prevent more serious engine problems down the road.

Performance Issues:

● Sluggish acceleration (noticeable hesitation when pressing the gas pedal)

● Rough idling or unstable engine running, especially when cold

● Engine stalling at stop lights or when coming to a stop

● Lack of power, particularly noticeable when climbing hills or towing

● Engine misfires that occur under load or at specific RPM ranges

Fuel System Problems:

● Poor fuel economy (sudden, unexplained drops in MPG)

● Rich air-fuel ratio (indicated by black smoke from exhaust)

● Lean air-fuel ratio (causing engine to run hot or ping)

● Hesitation or stumbling during acceleration

Warning Signs:

● Check engine light illumination (often with MAP sensor trouble codes like P0106-P0109)

● Failed emissions test due to improper air-fuel mixture

● Engine running either too rich or too lean at idle

● Unusual exhaust gas smells indicating incomplete combustion

Diagnosing MAP Sensor Problems

Before replacing your MAP sensor, it's wise to perform some basic diagnostics to confirm it's actually the source of your problems. Many symptoms of a bad MAP sensor can also be caused by other issues like vacuum leaks or faulty spark plugs.

Tools You'll Need:

● OBD-II scanner (even a basic Bluetooth model will work for reading trouble codes)

● Digital multimeter for testing electrical signals

● Vacuum gauge can be helpful for verifying manifold pressure

● Service manual for your specific vehicle's specifications

Step-by-Step Testing Procedure:

1.Scan for Trouble Codes: Use your OBD-II scanner to check for MAP sensor-related codes in the P0100 series. These codes can indicate circuit problems or range/performance issues.

2.Visual Inspection:

● Check the sensor itself for physical damage or contamination

● Inspect the wiring harness for frayed wires or loose connections

● Examine the vacuum hose (if equipped) for cracks or leaks

● Look for signs of oil or coolant contamination that could affect the sensor

3.Voltage Tests:

● Verify the 5-volt reference signal is present at the sensor connector

● Check that the ground wire has good continuity to chassis ground

● Measure the signal wire output at various engine conditions

4.Output Verification:

● At idle, a typical MAP sensor will output about 1-2 volts

● With the engine off but key on, it should read near atmospheric pressure (about 4-4.5V at sea level)

● The voltage should increase smoothly with engine load and RPM

5.Comparative Testing:

● Compare your readings to specifications in the service manual

● Check for correlation with other sensors like the BARO or MAF sensor

● Verify that changes in manifold pressure (by revving engine) produce appropriate signal changes

MAP Sensor vs. MAF Sensor: What's the Difference?

While both deal with engine air management, they serve different purposes and work in complementary ways:

MAP Sensor:

● Measures pressure in the intake manifold to determine air density

● Works with speed-density fuel calculation systems

● Common in many gasoline and diesel engines, especially older models

● Particularly important in turbocharged applications for boost control

● Can calculate engine load based on manifold pressure and RPM

MAF (Mass Air Flow) Sensor:

● Measures actual air mass entering the engine using hot-wire or hot-film technology

● Used in air-flow metering systems for more precise measurement

● Typically found in newer fuel-injected engines

● Directly measures the mass of air entering the intake tract

● Generally located between the air filter and throttle body

Many modern vehicles use both sensors together for more accurate engine management. The ECU cross-references data from both to ensure optimal air-fuel ratio under all operating conditions. When they disagree, it can trigger diagnostic trouble codes and affect engine performance.

When to Replace Your MAP Sensor

Consider replacement if any of the following conditions exist:

● Diagnostic tests confirm sensor failure through out-of-spec readings

● Cleaning the sensor doesn't resolve performance issues

● You're experiencing multiple symptoms simultaneously that point to MAP sensor failure

● The sensor shows physical damage, corrosion, or contamination that can't be cleaned

● You've ruled out other potential causes like vacuum leaks or wiring problems

For replacements, quality matters. While aftermarket options may be cheaper, OEM or reputable brands like Delphi Technologies and NAPA Auto Parts often provide more reliable performance and longevity. Look for sensors specifically designed for your vehicle's make and model to ensure proper operation.

Maintenance Tips for Longevity

To keep your MAP sensor working properly and extend its service life:

1.Regular Air Filter Changes: Dirty air filters allow contaminants into the intake system that can coat the MAP sensor. Follow your manufacturer's recommended interval.

2.Prompt Vacuum Leak Repairs: Any unmetered air entering the intake manifold will skew the MAP sensor readings and make it work harder to compensate.

3.Proper Cleaning Procedures: If cleaning is needed, use only approved electronic cleaner sprays. Never use brushes or compressed air that could damage sensitive components.

4.Routine Inspections: Include the MAP sensor and its connections in your regular maintenance checks, especially if you notice any performance changes.

5.Quality Fuel: Using poor quality gasoline can lead to carbon buildup that may affect sensor operation over time.

Conclusion

Your MAP sensor might be small and often overlooked, but its role in engine performance is enormous. From maintaining proper air-fuel mixture to preventing engine damage, this critical component deserves attention when problems arise. By understanding how it works and recognizing early warning signs, you can address issues before they lead to more serious (and expensive) problems.

Remember: When in doubt, consult a professional mechanic. Proper diagnosis ensures you fix the actual problem rather than just throwing parts at symptoms. Many auto parts stores offer free scanning services that can help identify MAP sensor issues, but for complex problems, a trained technician with proper diagnostic equipment may be needed to pinpoint the exact cause of your vehicle's performance issues.