What are Eddy Currents: Foundations, Effects, and Applications

Introduction

When we delve into electromagnetic effects, it’s natural to ask what are eddy currents: loops of electric current that form in conductors exposed to changing magnetic fields. Often called Foucault currents, these swirling flows bring to life Faraday’s Law—showing how variations in magnetic flux generate voltage—and Lenz’s Law, which dictates that induced currents oppose the very changes that produce them. From eddy current brakes slowing roller-coaster cars to nondestructive testing that probes metal integrity, these currents make possible applications reliant on magnetic damping while also posing challenges like unwanted eddy current loss.

Fundamental Principles

Eddy currents appear as swirling electrical currents that form in conductive materials subjected to time-varying magnetic fields. As explained by Faraday's Law, any change in magnetic flux passing through a conductor generates an electromotive force, leading to these circulating currents. Lenz's Law determines the flow direction: the eddying current will loop to oppose the original change in magnetic flux. This behavior becomes particularly noticeable in ferromagnetic materials with high magnetic permeability, where strong eddy currents emerge. The skin effect often accompanies this, where alternating magnetic fields concentrate the currents near the material’s surface.

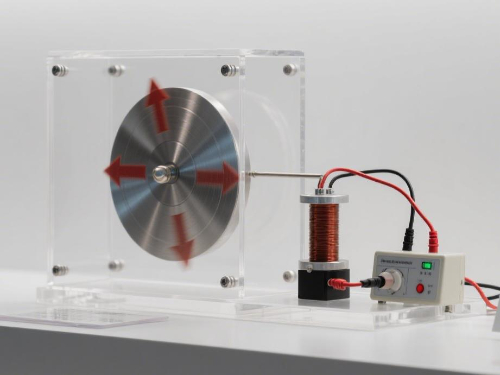

To see this in action, picture a powerful magnet passing near a flat metal sheet or slotted metal plate. The movement of the magnetic field relative to a stationary conductor creates electrical currents that rotate in specific directions—clockwise when flux decreases, counterclockwise when it increases. These current loops in turn generate their own magnetic field, often referred to as a secondary field, which interacts with the primary coil’s field or that of permanent magnets. The result is a Lorentz force that can either resist motion or convert kinetic energy into electrical energy or heat.

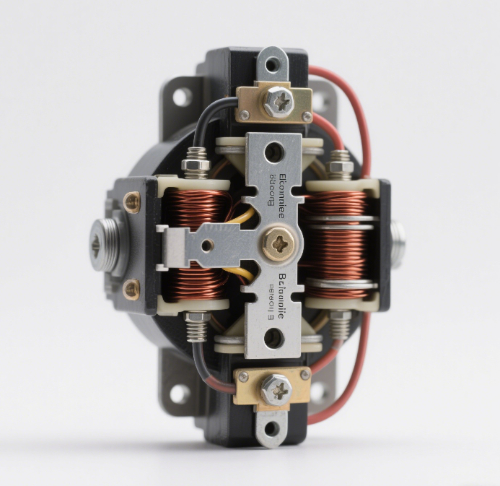

Answering the question of what are eddy currents also involves recognizing that they take place in loops within conductors; these loops within conductors can occur adjacent to nearby conductors or secondary coils that form part of a transformer core. In transformer applications, eddy currents in the metal cores contribute to transformer core losses, alongside hysteresis loss, diminishing efficiency. To reduce such losses, electromagnetic designers use laminated cores, metal fins, or slotted metal plates to break up current loops and limit continuous conductive paths.

Applications in Braking and Damping

One of the most common applications of eddy currents is electromagnetic braking. Eddy current brakes, also known as current brakes or magnetic drag systems, depend on these induced currents flowing in a conductor as it moves through alternating magnetic fields generated by permanent magnets or electromagnets. The induced currents generate magnetic damping forces that oppose the direction of motion, providing smooth, wear-free deceleration in roller coasters, trains, and industrial machinery.

In induction stoves and portable induction cooktops, the rapidly alternating magnetic field generated by a primary coil induces eddy currents in the ferromagnetic cookware. The eddy current loss within the pot or pan manifests as heat due to the resistance of the conductive material, effectively converting electrical energy to thermal energy. This principle also underlies induction heating systems, used in industrial applications to heat metal sheets or pieces of metal quickly and precisely.

Inspection and Testing

Eddy current testing (ECT) is a critical nondestructive testing (NDT) method for inspecting materials, detecting cracks, measuring coating thickness, and assessing metal fatigue. Eddy current testing instruments use secondary field sensors and powerful rare-earth magnets, such as neodymium magnets, or electromagnetic probes to induce a time-varying magnetic field in the test object. Variations in eddy currents—affected by conductivity, magnetic permeability, or the presence of flaws—alter the impedance of the probe’s coils, allowing technicians to map energy loss, current loops, and discontinuities without damaging the material.

Advanced NDT methods combine eddy current testing with analysis of skin effect and proximity effect, which influence the distribution of current density. In high-frequency alternating magnetic fields, currents concentrate near the surface (skin depth), while proximity to adjacent loops or conductive structures can redirect path lines, making detailed knowledge of magnetic field lines essential for accurate readings.

Challenges and Loss Mitigation

While eddy currents power many useful technologies, they also bring with them some significant downsides, especially in terms of energy efficiency. For example, in electric motors and generators, the presence of eddy current loss in magnetic cores and surrounding conductive parts leads to a drop in output performance. A similar story plays out in transformer cores, where eddy currents become a main source of heat buildup. When combined with hysteresis loss, these two effects represent a substantial chunk of the total energy loss—particularly in high-frequency applications. To counter these issues, designers frequently choose materials with lower magnetic permeability in specific sections or apply structural changes. Laminated metal cores and powdered metal designs are common strategies; both approaches help to break up closed loops and restrict the circulation of unwanted electrical currents.

Adding complexity, the skin effect becomes more prominent at higher frequencies. In these situations, eddy currents tend to stay near the outer edges of conductors. This limits the area available for carrying electrical currents, effectively increasing resistance and leading to more heat. While this behavior is advantageous in some scenarios—such as induction heating or certain RF applications—it’s problematic in contexts like high-capacity power transmission lines. There, the increased resistance due to the skin effect results in greater ohmic losses and diminished overall system efficiency.

Practical and Industrial Applications

Beyond braking and heating, eddy currents find roles in several industrial applications. In recycling centers, eddy current separators use rows of powerful magnets rotating above conveyor belts to induce currents in nonferrous metals like aluminum and copper. The resulting magnetic drag repels the conductive materials, separating them from other waste. Portable metal detectors employ coils excited by alternating magnetic fields to generate eddy currents in buried metallic objects; disturbances in these currents signal the presence of metal.

Electromagnetic damping is also used in sensitive instruments, such as seismometers or galvanometers, where eddy current dampers suppress oscillations and stabilize readings. Similarly, in magnetic levitation systems or contactless couplings, eddy current forces provide stable coupler action without mechanical wear.

Directional and Geometric Considerations

The direction of induced eddy currents follows closed loops in the plane perpendicular to the magnetic flux changes. In a uniform field, counterclockwise loops oppose flux increase, while clockwise loops oppose flux decrease. When using alternating magnetic fields, the patterns of induced currents flip with each cycle, leading to alternating magnetic drag forces. Manipulating the geometry of conductors—such as using slotted metal plates, metal fins, or stacks of sheets of metal—enables precise control over both current loops and resulting energy losses.

Undesirable Effects and Optimization

Eddy currents, while useful, can cause form of braking in cases where magnetic drag is unintended, such as in the damping on insulators or in adjacent loops within electronic enclosures. Induction cooktops must balance eddy current loss in the cookware with minimal loss in the induction coil itself. In electric fields and electromagnetic fields overlapping, secondary fields can induce stray eddy currents in nearby conductive materials, leading to electromagnetic interference.

Designers often simulate eddy current distribution and Lorentz forces to forecast losses and heating patterns. Techniques such as finite-element analysis help visualize current loops and magnetic field moves within complex geometries, guiding choices of conductive materials, magnetic core shapes, and coil configurations.

Conclusion

From understanding what are eddy currents to developing advanced applications, the study of eddy currents bridges fundamental electromagnetic theory and diverse engineering solutions. By harnessing principles of electromagnetic induction, magnetic flux manipulation, and the law of induction, engineers can create eddy current brakes for kinetic energy control, induction heating systems for rapid thermal processing, and eddy current testing tools for non-destructive evaluation. Simultaneously, careful material selection, geometric optimization, and loss mitigation strategies ensure that eddy currents serve us efficiently without unwanted energy loss. As technology advances, the interplay between electrical currents, magnetic field lines, and conductive materials continues to inspire innovative applications and refined control over these dynamic currents.