How to Read Electrical Schematics?

What is a schematic diagram?

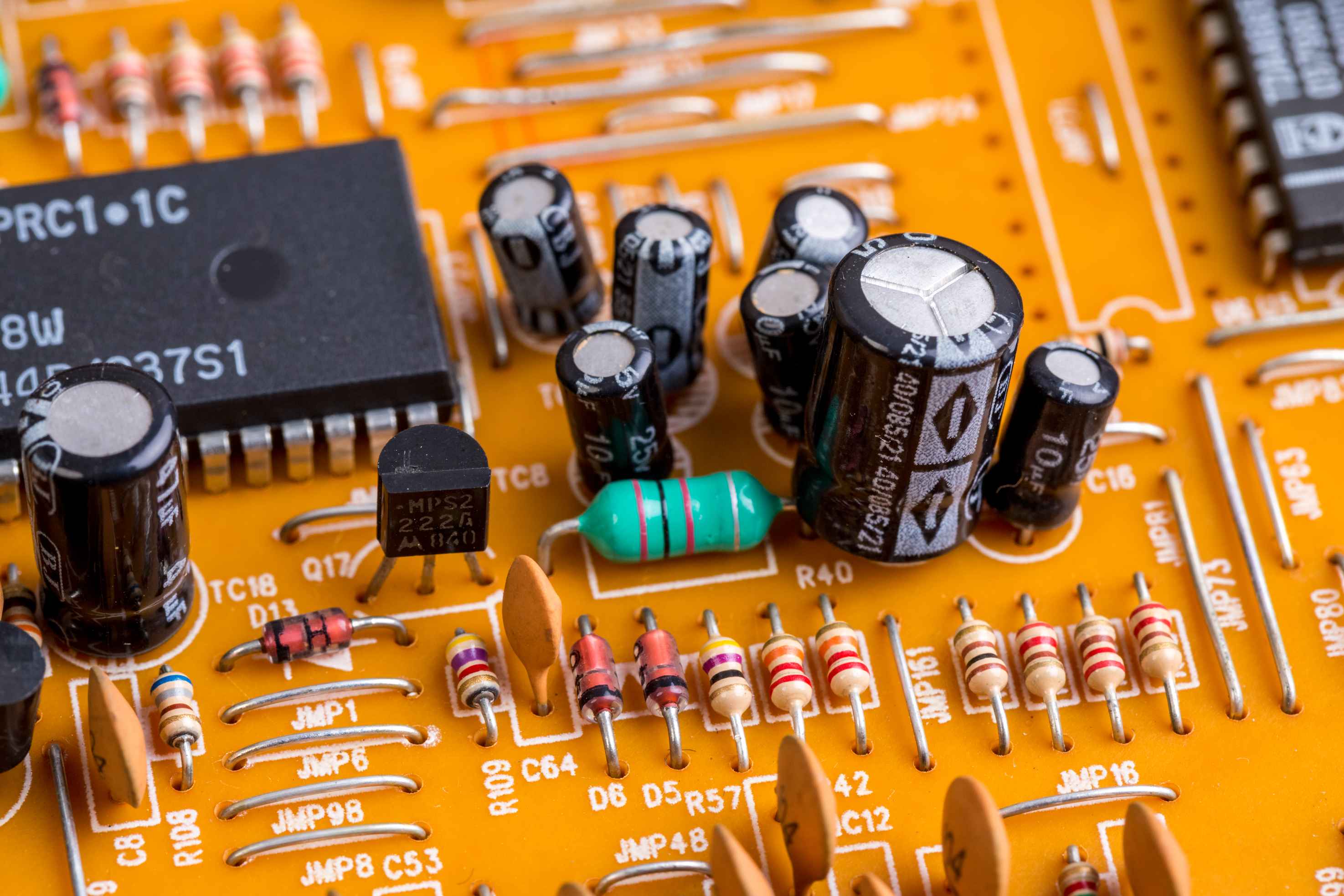

In engineering field,the electrical schematic diagram serves as the cornerstone of designing circuit from scratch, closely linked to subsequent processes such as assembly, PLC programming, human-machine interface, equipment installation, and operational maintenance. It is a graphical document used to depict the functionality and working principles of an electrical system. Through electrical symbols and parallel lines, it illustrates the interactions and ground connections between electrical components and is typically employed for designing, installing, maintaining, and troubleshooting electrical equipment and electronic systems.

Electrical schematic symbols are drawn based on the working principles of control circuit diagrams, characterized by their simple structure and clear hierarchy. They are primarily used for studying and analyzing electrical circuit operation principles in engineering field,. So, do you know how to read electrical schematics?

How to read a schematic diagram?

An electrical engineer must possess two key skills: creating and interpreting blueprints. The design of electrical diagrams must adhere to industry standards to facilitate maintenance personnel and other professionals in swiftly resolving electrical issues. These designs also ease the process of electrical wiring diagram, preventing situations where workers cannot interpret the electrical diagrams or connect symbols for wires correctly.

Upon receiving a blueprint, one should first thoroughly examine the main title block and any relevant annotations, such as the drawing directory, technical notes, bill of materials for electrical components, and construction instructions. This, combined with existing electrical knowledge, helps form a clear understanding of the common type, nature, and purpose of the electrical diagram, allowing for an overall grasp of its scope and key points.

Reviewing Schematic and Block Diagrams

Schematic symbols and block diagrams provide a general representation of power system or subsystem’s physical components, interrelationships, and primary features. Therefore, it is essential to study the simple diagrams next to fully understand their operational principles. Single-line block diagrams are often used for these, although low voltage level distributions may partially employ multi-line representations.

Examining Circuit Diagrams

Circuit diagrams are the core of electrical blueprints and the most content-rich and complex to decipher. When reading a circuit diagram, one must identify all graphical and textual basic symbols, understand the function of each part, and distinguish between the main and auxiliary circuits, as well as AC and DC basic circuits.

Analyzing Main and Auxiliary Circuits

When doing main circuit analysis, it is typically read from bottom to top, starting with the load, moving through control electronic devices, and finally reaching the power source. For auxiliary circuits, the approach is top to bottom and left to right, starting with the main power supply, then sequentially examining each branch to analyze the operation of passive components and their control over the main circuit. Attention should also be paid to the connections between electrical systems and electronic systems.

Through main circuit analysis, one can determine how the load draws power, which components the power lines pass through, and why. Studying the auxiliary circuit reveals its structure, the interactions and control relationships among components, their operations, and the relationship between the auxiliary and main circuits, ultimately clarifying the entire electronic circuit's operating principles and rationale.

Comparing Wiring Diagrams with Circuit Diagrams

Cross-referencing the wiring and circuit diagrams aids in understanding the electrical wiring diagram. When reading a wiring diagram, follow negative terminal and positive terminal markings and integrated circuit labels from the power source onward to clarify the common return path and connection methods. Determine how each branch forms a closed loop through different components. Internal and external circuits on a distribution panel must be connected via terminal circuit blocks. The number of wires within the panel corresponds to the signal connections, ensuring that external connections between wires at the matching output terminal points. To comprehend the wiring diagram thoroughly, one must pay attention to the terminal block's wiring details, both inside and outside the distribution panel.

Keypoint of How to Read Electronic schematics

1.Analyze the Main Circuit

Begin with the main circuit and analyze the control requirements for each motor and executing device, focusing on fundamental control elements such as motor startup, directional control, and braking.

2.Analyze the Auxiliary Circuit

Examine the power supply of the auxiliary circuit, clarifying the function of each electrical component within the simple circuit and their interdependent relationships.

3.Analyze Interlock and Protection Mechanisms

Given the high safety and reliability demands of production machinery, it is essential to incorporate a series of electrical protections and necessary interlocks in addition to reasonably selecting the drive and control schemes.

4.Analyze Special Control Elements

Certain control systems may include relatively independent special components that are not closely related to the main or control circuits. These might include product counting devices, automatic detection complex systems, circuit breakers, and automatic temperature control devices. These components often form a complex system of their own, and their analysis can reference the aforementioned methods while flexibly applying knowledge of electronics, AC technology, industrial automation systems, detection, and conversion techniques.

5.Overall Inspection

After breaking down and gradually analyzing the working principles of flow of circuit and the control relationships between different parts, it is crucial to reassemble and inspect the entire control systems for any omissions. A comprehensive examination from an overall perspective further ensures a clear understanding of the role, operational process, and key parameters of each electrical component within the circuit diagram.

The Significance of Reading Electrical Schematics

1.Foundations of Technical Understanding

• Symbol and Terminology Mastery: Ability to recognize international standard capacitor symbols (such as those from IEC, ANSI) for components like momentary switches, relays, sensors, motors, etc., and understand terminology such as normally open/normally closed contacts and standardized symbols.

• Circuit Logic Analysis: Essential tool to analyze electric current paths, voltage distribution, and signal flow, assessing the control logic between components, such as interlocking circuits and timing relationships.

• Complex System Hierarchy Decomposition: Distinction between main circuits (power section) and control circuits (logic section), understanding how they work in unison, such as the coordination between contactors and PLCs in motor start/stop control.

2.Core Competencies in Engineering Practice

• Design and Optimization: During circuit design, able to evaluate topology structure rationality from electric schematics (e.g., redundancy design, protective circuit configuration) and propose improvement strategies (such as wiring methods to reduce electromagnetic interference).

• Installation and Commissioning: In guiding on-site wiring, translating complex schematics into actual wiring diagrams to prevent incorrect connections (e.g., reverse motor rotation due to phase sequence errors); verifying design by measuring key parameters (voltage, direct current waveform) during commissioning.

• Fault Diagnosis Efficiency: Quickly pinpointing fault locations using schematic symbols, employing methods like sectional isolation to narrow down issues, and utilizing multimeters, oscilloscopes to detect abnormal input signals and analyze potentially failing components (such as blown fuses or stuck relay contacts).

3.Bridge for Cross-disciplinary Collaboration

• Integration with Electronic Systems: Understanding interfaces between electrical and mechanical key aspects in mechatronic equipment (e.g., how servo motor encoder feedback integrates into controllers), ensuring electrical signal synchronization.

• Software Control Integration: Interpreting the relationship between PLC ladder diagrams, HMI interfaces, and electrical schematics, assisting programmers in writing control logic (e.g., dual response mechanisms for emergency stop buttons in hardware and software).

• Standardized Communication: Using schematics as a universal language during project meetings or documentation to minimize communication ambiguities (such as clarifying sensor input addresses corresponding to PLC modules).

4.Assurance of Safety and Compliance

• Application of Safety Standards: Identifying safety circuits in schematics (such as safety relays and emergency stop circuits) to ensure compliance with standards like ISO 13849, preventing design oversights leading to personal injury.

• Regulatory Compliance Verification: Checking whether drawings meet local electrical regulations (such as NEC, IEC 60364), including grounding methods, conductor sizing, short-circuit protection levels, etc.