FFC vs FPC Connector: Understanding the Key Differences and Applications

In our daily lives, we more or less come into contact with connectors. For factory producers, connectors are used every day. With the differences in common application objects, frequency, power, and application environment, there are various connector types. I wonder how much everyone knows about FFC vs FPC connectors? This article will introduce these two types of connectors, as well as their differences and common types.

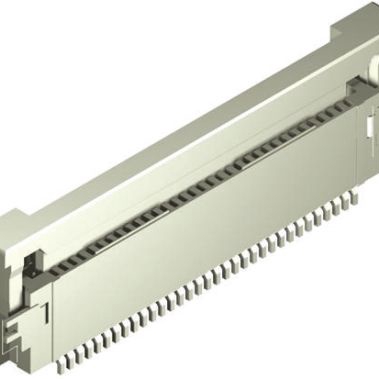

Understanding FFC Connector

First, let's introduce the Flexible Flat Cable connector. The ffc connector is mainly composed of a copper conductor layer, an adhesive film, and a reinforcing plate. The copper conductors (tinned copper) include round conductors and flat copper conductors. The FFC adhesive film comes in black and white, and the reinforcing plate comes in transparent blue, transparent white, transparent red, and black. This connector has the advantages of small terms of size, convenient use, good contact, and a wide range of applications.

The surface of the flat flex cable connector conductor is treated, and it has superior reliability after insertion. The FFC connector is relatively easier to weld compared to the ordinary FC, is not easy to be oxidized, and can undergo additional processing such as bending and shaping.

The ffc connector is a kind of flexible flat cable connector. It is a type of cable formed by bonding PET insulating material and ultra-thin tinned flat copper wires through high-tech automated processes.It has the characteristics of being flexible, bendable and foldable at will, thin in cable thickness, small in connector size, simple to connect, easy to disassemble, and easy to solve electromagnetic shielding (EMI).

Compared with traditional ribbon electrical cables, due to the use of an insulating film that is only half as thick, the Flexible Flat Cable is smaller, lighter, and thinner. It is most suitable for the miniaturization and high density of machines. Moreover, its superior flexibility and bendability give it with characteristics comparable to those of flexible circuit boards.

In addition, since the Flexible Flat Cable connector does not use PVC, there will be no chloride pollution to the environment when it is discarded. The polymer film is bonded to the conductor, and there is no phenomenon of the conductors at both ends of the traditional ribbon electric cable floating up.

Understanding FPC Connector

The main function of the flat flex cable connector is to connect the printed circuit board (PCB) and the flexible circuit board (FPC), achieving mechanical and electrical connections. Nowadays, flexible circuit connectors are widely used in a variety of electronic devices, including LCD and LED liquid crystal displays, scanners, digital cameras, game consoles, tablet computers, laptops, in-vehicle entertainment systems, and so on.

In terms of product types, flexible circuit connectors with a pitch size of 0.5mm are the mainstream, and there are also products with a pitch size of 0.3mm for higher-density cable connection requirements.

Key Differences Between FFC and FPC Connectors

There are some differences between FFC (Flat Flexible Cable Connector) and FPC (Flexible Printed Circuit Board) in terms of manufacturing process, structural design, cost-effectiveness, and application scenarios. These differences determine their respective application scopes and market positions.

Product Definitions

FFC (Flexible Flat Cable Connector): It is mainly used to achieve electrical connections inside electronic devices or between devices. It is a flexible cable connector presented in a flat structure.FPC (Flexible Printed Circuit Board): It is a circuit board manufactured through a printing process with a flexible substrate as the carrier, and is widely used in various electronic devices that require thin, light, and bendable characteristics.

Manufacturing Process and Structural Characteristics

Manufacturing Process and Structure of FFC:

The manufacturing process of flat flex cable is relatively simple. It is mainly composed of upper and lower layers of insulating foil films and a flat copper foil in the middle. During the production process, the flat copper foil is first placed between the two layers of insulating foil films, and then they are tightly bonded together through processes such as hot pressing to form an integral structure. This manufacturing method makes the production efficiency of FFC relatively high, and the cost is relatively low.

Due to the adoption of a simple sandwich structure, the finished product of FFC is relatively simple, and the overall thickness is relatively thick. However, this structure also endows flat flex cable with good flexibility and a certain degree of mechanical strength, which can meet the basic requirements for flexible materials in general electronic devices. At the same time, it is relatively easy to achieve the equal-length design of the FFC lines, and there is basically no time delay problem during electrical signal transmission, which gives it certain advantages in some application scenarios with high-flex application for electrical signal high-speed transmission and stability.

Manufacturing Process and Structure of FPC:

The manufacturing process of FPC is relatively complex. It uses flexible copper-clad laminates (FCCL) as the base material, and processes the copper foil through chemical etching process to obtain the required circuit routing and shape. Specifically, a layer of photosensitive ink is first coated on the surface of the FCCL, and then the parts of the circuit that need to be retained are exposed through processes such as exposure and development. Finally, the unnecessary parts of the copper foil are removed through chemical etching to form the required circuit pattern. According to different design requirements, FPC can be made into single-sided, double-sided, or even multi-layer flexible circuit boards. This complex design enables FPC to achieve more precise and complex circuit designs, meeting the needs of various high-performance and high-density electronic devices.

The lines of FPC are formed by etching, so the line conductors are relatively rough, and there is a large error in the width of the lines. Compared with FFC, FPC is thinner and lighter, and can better adapt to the development trend of miniaturization and thinness of electronic devices. However, since it is more difficult to achieve the equal-length design of the FPC lines, there may be a certain time delay during digital signal transmission, which limits its application in some application scenarios with extremely high requirements for electrical signal high-speed transmission to a certain extent.

Cost-effectiveness

In terms of manufacturing process and material cost, the production process of FFC is relatively simple, and the required equipment and process flow are relatively basic, so its production cost is relatively low. In addition, the main materials of FFC are insulating foil films and flat copper foils, and the market prices of these materials are relatively stable, further reducing its cost. For most enterprises, choosing FFC connectors can effectively reduce production costs and improve the market competitiveness of products while ensuring basic functions.

The design complexity of FPC and advanced equipment and complex process flows are required, such as exposure machines, developing machines, etching machines, etc., which makes its production cost relatively high. At the same time, the material cost of FPC is also relatively high, especially the price of high-performance materials such as flexible copper-clad laminates fluctuates greatly, further increasing its cost. Therefore, the cost of FPC is relatively high, which limits its variety of application in some cost-sensitive application scenarios to a certain extent.

Application Differences:

Wide Application of FFC connectors: Due to the advantages of low cost, simple structure, and stable electrical signal transmission, FFC has been widely used in many fields. For example, in the field of consumer electronics, FFC is often used to connect the displays and motherboards of mobile phones, tablets, laptops and other devices to achieve electrical signal transmission; in the field of automotive applications, FFC can be used to connect electrical components such as automotive instrument panels and central control screens to meet the reliable connection needs of internal electronic devices in vehicles; in the field of industrial automation systems, FFC can be used to connect various sensors, controllers and other devices to achieve digital signal transmission and control between industrial devices. In short, with its cost advantages and good performance, FFC occupies an important market share in many fields.

High-end Application of FPC connectors: Although the cost of FPC is relatively high, its unique performance advantages make it widely used in some high-end fields and high-performance devices. For example, in portable communication devices such as smartphones and tablets, FPC is used to achieve a more compact, thinner and lighter design to meet the requirements of miniaturization and high performance of the devices; in the field of medical devices, FPC can be used to manufacture flexible circuits in wearable medical devices and medical instruments to achieve the portability and flexibility of the devices; in the field of aerospace, the lightweight and high-reliability characteristics of FPC make it an ideal electronic connection between devices solution. These high-end application fields have extremely high requirements for the performance and reliability of electronic devices, and the high performance of FPC can meet these stringent requirements, so it has an irreplaceable position in these fields.