An In-depth Analysis of Barrel Connector Sizes and Applications

To make the power connector decisions for modern electronicapplication, standard barrel connectors stand out as one of the most wide range of using interface types. However, barrel connector sizes and broad range of adaptation solutions often perplex engineers and technicians. This article aims to systematically break down key technical points from basic structures to special application scenarios, such as converting a 5mm bullet connector to an IC5 female head and selecting appropriate sizes for 12V adapters, while discussing the core logic of design of barrel connectors through practical cases.

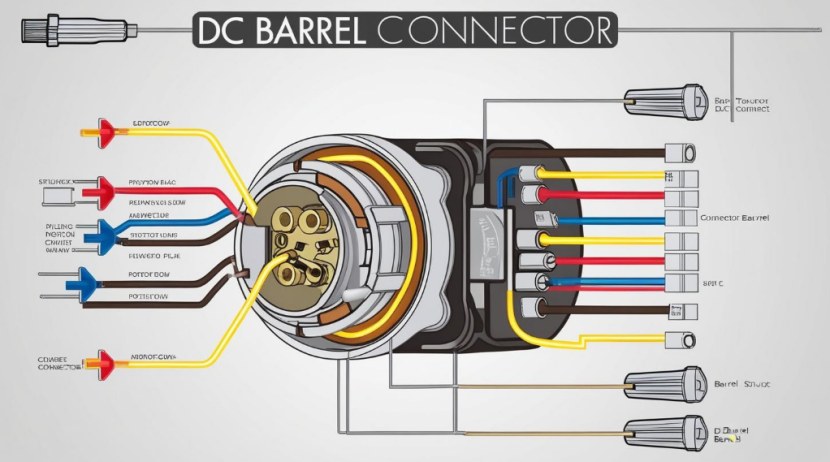

Structural Principles and Core Parameters of DC Barrel Connectors

The fundamental form of barrel connector consists of concentric cylindrical layers of metal conductors: an outer sleeve, typically made from nickel-plated brass, and an centre pin with special surface treatment to reduce connector contact resistance. This design ensures mechanical strength while achieving reliable electrical connection through elastic contact structures, with typical electronic products enduring over 10,000 mating cycles. Three critical dimensions determine connector compatibility in real applications: outer diameter, which dictates the physical match adapter plugs between with device ports (common specs include 5.5mm, 3.5mm); central pin diameter, controlling the contact precision of the central conductor (with mainstream specs being 2.1mm and 2.5mm); and overall length, influencing device casing design—too short may lead to poor contact of outer plug, too long could cause short-circuit risks.

The International Electrotechnical Commission (IEC 60320) specifies a standard polarity configuration where the centre pin is positive (+) and the outer ring negative (-), though some medical equipment and industrial control systems adopt reverse designs. A 2019 survey in the North American market revealed that approximately 17% of equipment damage cases were due to polarity configuration errors, necessitating careful verification of equipment markings by technicians during selection. For non-standard polarity devices, specialized polarity converters or custom cables can be employed, ensuring the converter's current carrying capacity exceeds the device’s rated value by over 20%.

Detailed Analysis of 5mm Bullet to IC5 Female Conversion Technology

In high-power applications like drones and RC model cars, the 5mm bullet connector is favored for its excellent current carrying capacity. Featuring a solid copper core with silver plating that reduces contact resistance below 0.15mΩ, it maintains temperature rise under 35°C at continuous current rating of 30A. The accompanying IC5 interface, designed for fifth-generation lithium batteries, uses a dual spring tab design and high-temperature nylon housing to enhance peak current capability up to 150A, and includes anti-misplug latches with a cycle life of 500 insertions.

When making a 5mm to IC5 conversion cable, conductor choice directly influences system safety. It is recommended to use 12AWG silicone insulated wire, with a cross-sectional area of 3.31mm², capable of stably carrying 40A even at 70°C ambient temperatures. The crimping process requires hydraulic pliers exerting over 8 tons of pressure to ensure a metallurgical bond between terminal and wire core, avoiding thermal stress from traditional soldering methods. Post-assembly, heat shrink tubing must completely cover metallic contact areas to provide insulation and prevent oxidation. Tests by a drone manufacturer showed that properly made conversion cables withstand 20G impact during vibration testing, with contact resistance variation rates below 3%.

Selecting 12V Adapter Sizes and Common Troubleshooting

Amidst the myriad of 12V power adapter specifications on the market, the search query "12 adapter what size tip" reflects widespread user confusion. Among mainstream specs, the 5.5×2.1mm combination supports up to 60W output, common in routers and surveillance cameras; whereas higher power devices like LED displays or industrial equipment often use the 5.5×2.5mm spec, enabling up to 90W power supply due to increased contact area. For low-power devices like network switches, the 4.0×1.7mm micro interface saves space and guarantee right-angle plug configuration.

To address mismatched sizes, a step-by-step troubleshooting method can effectively resolve issues: first, use a digital caliper with 0.01mm precision to measure the existing barrel plug, ensuring accurate measurements by removing surface oxides; next, verify the device label for positive voltage/current parameters, especially leaving a 20% margin for the nominal current value; for non-standard interfaces in special scenarios like medical equipment (e.g., 4.8×1.7mm), the XH-M602 adjustable DC barrel plug can be chosen, allowing fine adjustments within a 0.5mm range via a knob mechanism. Recently emerging smart adapters with built-in auto-recognition chips dynamically adjust output voltage and accommodate various sizes, though they cost about 40% more than traditional solutions.

Common Barrel Connector Size Chart and Engineering Selection

Globally accepted sizing standards include branches like EIAJ and IEC, with EIAJ-01 (5.5×2.5mm) dominating consumer electronics, while industrial equipment leans towards enhanced EIAJ-05 (6.5×3.1mm) specs. Special applications have spurred many custom solutions: hearing aids use a gold-plated 3.0×1.1mm micro-interface to maintain contact resistance below 0.8mΩ; military-grade 7.9×5.5mm non-standard connectors feature stainless steel housings and self-locking mechanisms for stable operation in extreme environments from -55°C to 125°C.

When selecting specafic style of connector, multiple parameters need comprehensive consideration: current carrying capacity may initially be estimated using I_max = conductor cross-sectional area (mm²) × 5A, but current degradation due to temperature rise should be considered, suggesting actual use values not exceed 80% of calculated values. In terms of environmental adaptability, industrial-grade product chassis must meet IP54 protection levels and endure 96 hours of salt spray testing without corrosion. The choice of certification systems is equally critical, with North American markets mandating UL1977 certification, while the European CE certification under EN60320 stipulates specific flame resistance for insulating materials.

Fault Diagnosis and Technological Innovation Trends

Common faults often stem from mechanical wear or oxidative corrosion, with contact failure diagnosis achievable through a four-step method: visually inspect for blackening or pitting on contact surfaces; measure contact resistance with a 1A test current for accuracy; assess insertion force to determine spring tab failure, maintaining standard values between 2-5N; X-ray inspection can reveal weld point cracks invisible to the naked eye. Professional repairs require strict control of soldering temperatures at 350°C±10°C, employing silver bearing solder to reduce contact resistance, followed by a 500VDC/1-minute withstand voltage test.

Technological advancements are driving connectors towards intelligence: integrated sensors can monitor temperature and current parameters in real-time, with automatic circuit cut-offs during abnormal temperature rises; embedding NFC chips allows devices to recognize connector specs, fundamentally eliminating risks of incorrect integrated plug; graphene coating technology lowers contact resistance by 40%, paired with liquid metal sealing processes to achieve IP69K waterproof ratings. The International Standards Organization's ongoing development of IEC 62680-2 aims to realize USB PD protocol compatibility with traditional barrel interfaces, potentially reshaping the modern power supply designs for the coming decade.

In the simultaneous technological tide of miniaturization and high currents of power supplies demand for electronic devices, the sizing system of DC barrel connectors continues to uphold classical design stability while incorporating innovative achievements in new materials and processes. From 5mm bullet to IC5 interface transition solutions, from the mystery of 12V adapter sizes to futuristic smart connectors, understanding the engineering logic behind size parameters will help technicians navigate the complex world of interfaces to find optimal solutions. As new IEC standards emerge, professionals are advised to stay informed on standards updates, reserving ample compatibility space in device design and maintenance to accommodate impending technological changes.