What is A DIP Switch

Definition: What is a DIP Switch?

dip switches (Dual In-line Package Switch) are integrated mechanical switching electronic components that are widely used in the hardware configuration of electronic devices. Its core feature is the dual in-line package (DIP), which integrates multiple independent miniature switches in two parallel rows of contact pins in the same module, each of which can independently control the circuit on and off. Standard DIP switches typically contain 2 to 12 switching units (e.g., common 4-and 8-position DIP switch), each switch switch switching ‘ON/OFF’ (ON/OFF) via a toggle switch or slide switch at the top, with the states usually identified by identifiers (e.g., ‘1/0 ‘ or ‘ON/OFF’) or colour (e.g. black/white).

Types of DIP Switches

DIP (Dual Inline Package) switches come in several variations, each designed for specific use cases based on their actuation method, mounting style, and environmental durability. Below, we explore the five main types of DIP switches.

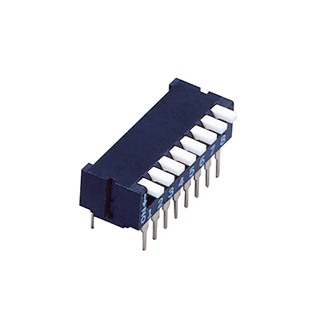

Slide DIP Switches

Slide DIP switches are the most common type of DIP switch, featuring a horizontal sliding mechanism. In terms of appearance, multiple sliders are arranged in two columns. Clear markings like “ON” and “OFF” are usually found on the sliders, enabling users to operate them intuitively. Its working principle is based on horizontal mechanical displacement. By toggling the sliders, the contact state of the internal metal contacts is changed, thus achieving the conduction and disconnection of the circuit.

Regarding functional characteristics, these switches mostly adopt a single pole, single throw design and support 2-to-12-bit configurations to meet various coding requirements. In the industrial control field, they are commonly used for setting device addresses. For example, in an RS485 bus communication system, slide DIP switches can quickly assign addresses to slave devices, ensuring the orderly progress of data communication. In smart home devices, they can configure device IDs, facilitating the system to identify and manage different electronic devices.

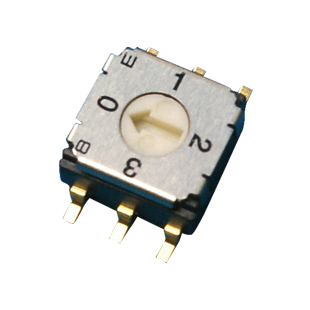

Rotary DIP Switches

Rotary type DIP switches are circular in shape. Operationally, different positions are selected by rotating the knob. Their internal structure contains multiple contacts. Through rotation, the switching between different contacts is achieved to complete binary or hexadecimal code settings.

Due to the design characteristics of rotary switches, only one bit changes between adjacent positions, effectively reducing signal jitter. In the field of communication devices, they are often used for baud rate selection. For instance, in modems and serial port devices, the transmission rate can be accurately set according to actual communication requirements. In automotive electronic systems, they are used to adjust the backlight brightness of the dashboard. Users can achieve multi-level brightness adjustment through rotation, enhancing the driving experience.

Piano DIP Switches

Piano DIP switches feature a push-button style. Their design is inspired by piano keyboards. Each button works independently, and when pressed, it changes the circuit state. These switches were widely used in the early days and were often found in hardware devices such as old-fashioned computer motherboards and game console controllers.

Functionally, some piano types DIP switches support continuous fine-tuning of resistors or capacitors, enabling precise control of device parameters. For example, in old-fashioned audio device type, parameters such as volume and pitch can be adjusted. In early industrial instruments, they were used to calibrate various parameters of the devices, ensuring the accuracy of measurements.

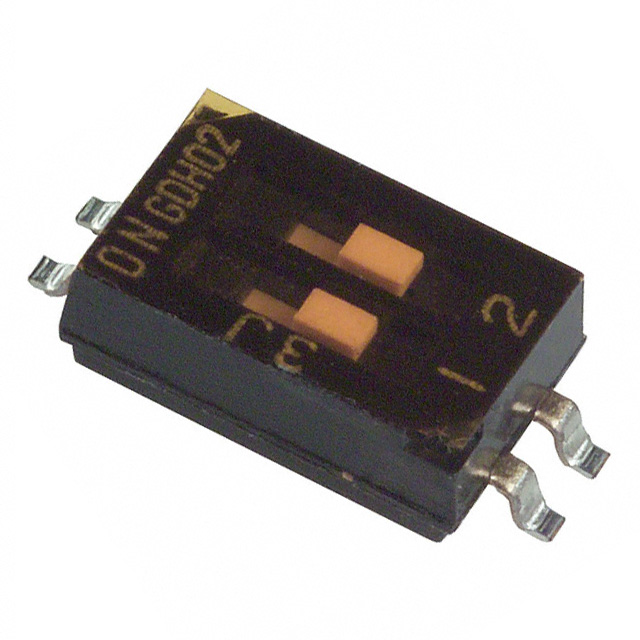

Surface-Mount (SMD) DIP Switches

Surface Mount DIP switches are specifically designed for modern, compact printed circuit boards. Compared with traditional through-hole version DIP switches, SMD switches are smaller in size. Their contact terminals are directly soldered onto the surface of the circuit board, greatly saving circuit board space and improving the integration of electronic products.

SMD DIP switches have excellent electrical properties. The soldering process mainly uses reflow soldering, which is highly compatible with modern automated production processes. In the consumer electronics field, such as in smartphones and wireless earphones, SMD switches are used for function switching and mode selection. In Internet of Things modules, they are used to configure device operating mode, promoting the miniaturization and intelligence of IoT devices.

Sealed and High-Reliability DIP Switches

Sealed and high-reliability DIP switches are specifically designed for the industrial field or outdoor environments. Structurally, special sealed device such as O-rings or epoxy resins are used to isolate the interior of the switch from the external environment, effectively preventing the dust ingress and ensuring stable operation in harsh environments.

The contacts of these switches are specially treated, featuring high wear resistance and corrosion resistance. They can withstand large currents and voltages and have a long service life. In the industrial control field, they are commonly used in programmable logic controllers (PLCs), variable frequency drives, and other devices to ensure the stable operation of industrial production. In outdoor communication base stations, they are used to set device parameters. Even under harsh conditions such as wind, rain, and sand, they can ensure the normal operation of communication devices.

How Does a DIP Switch Work?

Although there are various type of switch, they share the same working principle. They all revolve around changing the contact states through the internal mechanical structure, thereby achieving circuit control and device configuration.

In terms of the internal mechanism, DIP switches contain metal contacts and conductive traces. Take the slide DIP switch as an example. When users toggle the slider, the slider drives the connecting piece to move horizontally. The connecting piece changes the contact state of the metal contacts, and accordingly, the circuit is either conducted or disconnected. The conductive traces connect these contacts to the electronic device's circuit, forming a complete electrical path.

DIP switches adhere to the binary on/off logic, where “1” represents on and “0” represents off. Each switch position corresponds to 1-bit information. By combining the states of different switch positions, complex binary encodings can be expressed. For instance, an 8-bit DIP switch can represent 2⁸, that is, 256 different states.

DIP switches play a significant role in device configuration. In the RS485 bus system for industrial settings, addresses are assigned to slave devices by setting the states of DIP switches, thus establishing an orderly electronic communication network. In communication devices, rotary DIP switches change the baud rate settings by switching between different contacts, meeting diverse electronic communication requirements. Additionally, in circuit design, DIP switches can function as jumpers, flexibly selecting different electronic circuit paths. For example, on microcontroller development boards, different startup modes can be selected via DIP switches to achieve customized functions.

Advantages of DIP Switch

Intuitive Operation

DIP switches typically employ simple operation modes such as sliding, rotating, or pressing. In consumer electronics, users can quickly pair receiver and transmitter frequencies for garage door openers by toggling the sliding DIP switches without additional tools, making the process accessible to all users.

Flexible Configuration

DIP switches support various bit configurations, ranging from basic 2-position to complex 12-position setups. By combining "ON/OFF" states, they generate diverse binary codes. In computing and networking, DIP switches on motherboards enable flexible adjustments of CPU multipliers and memory frequencies, catering to diverse user needs for device performance.

High Reliability

Most DIP switches feature mechanical structures, which remain unaffected by electromagnetic interference or system failures, unlike software-based configurations. In industrial automation, DIP switches configure addresses and communication baud rates for Programmable Logic Controllers (PLCs), ensuring stable inter-device communication even in harsh environments and safeguarding industrial network reliability.

Versatile Adaptability

DIP switches suit a wide range of applications, from precision-controlled audio equipment to aerospace systems demanding extreme stability. In avionics, they configure flight parameters and electronic communication frequencies to ensure flight safety. In retro gaming consoles, players use DIP switches to adjust game difficulty and lives for personalized experiences.

Cost-Effective Solution

DIP switches have simple structures, low manufacturing costs, and easy installation without complex debugging. In mass-produced electronics like garage door openers and remote controls, DIP switches offer an economical configuration option due to their cost advantages.

Role of DIP switches: Common Applications of DIP Switches

In the realm of consumer electronics, DIP switches are widely applied in televisions, remote controls, and garage door openers. In the early days, televisions utilized DIP switches to set channels and volume levels. Some high - end models also employ them to adjust picture ratios and color modes. In remote controls, DIP switches encode devices, enabling control over multiple devices. Garage door openers rely on DIP switches to match the frequencies of receivers and transmitters, ensuring operational safety.

Computing & Networking

DIP switches play a crucial role in computer motherboards, routers, and industrial personal computers. On motherboards, DIP switches are used to set parameters such as CPU multiplier frequencies and memory frequencies, catering to the performance requirements of different users. In routers, DIP switches configure network parameters like subnet masks and VLANs, optimizing network layouts. Industrial personal computers use DIP switches to set serial port parameters, guaranteeing stable contact between devices and other industrial equipment.

Industrial Automation

In industrial applications scenarios, DIP switches are used for parameter settings of programmable logic controllers (PLCs) and calibration of electronic equipment. In PLCs, DIP switches determine device addresses and communication baud rates, ensuring the stable operation of multiple devices in industrial networks. During the calibration of electronic equipment, DIP switches adjust sensor thresholds, ensuring the accuracy of equipment operation.

Legacy Systems

In legacy systems like retro gaming consoles and arcade machines, DIP switches are used to adjust game difficulty levels and set the number of lives. Players can customize their gaming experiences according to their preferences through DIP switches.

Automotive & Aerospace

DIP switches also play a significant role in the automotive and aerospace sectors. In the on - board diagnostics (OBD) systems of cars, DIP switches set diagnostic modes and communication protocols, facilitating fault detection by maintenance technicians. In avionics equipment, DIP switches configure flight parameters and communication frequencies, ensuring flight safety.