Understanding the Symbol of a Fixed Resistor

When mention the word"resistor", what first come to your mind? Preset resistors? Magneto resistors? Discrete resistors? Network resistors? Or anything else...

No matter which special type you are thinking about, the resistors can play a crucial role when embedded onto a circuit board or used in other ways. So now, let's explore the symbol of Fixed Resistors,which looks simple but plays an important role in various applications.

History of a Fixed Resistor

The inventor Otis Frank Boykin, recognized for creating the wire precision resistor on June 16, 1959, was born in Dallas, Texas, on August 29, 1920.

The first resistors were made from metal materials instead of resistive materials, however, it is plausible that carbon was used in the initial resistor designs. This material made up the filament of the initial early incandescent light bulb credited to Thomas Edison, documented in a US patent from 1879.

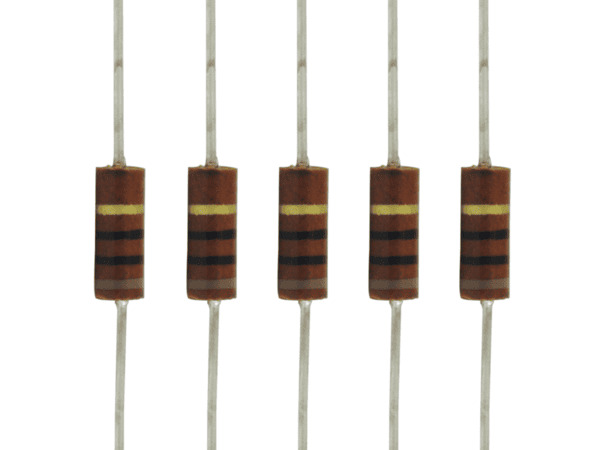

Carbon composition resistors are likely among the oldest resistor types, created from a blend of carbon powder and a binding substance, which is then shaped into a cylindrical form and baked. Early 20th century resistors, essentially uninsulated, were dipped in paint to cover their entire body for color-coding.

Definition of a Fixed Resistor

Fixed resistors are the most common type of resistor in electrical circuits. A fixed resistor is an circuit element that has a fixed, defined electrical resistance which is not adjustable. They take in voltage and limit the current passing through them, resulting in a lower voltage while dissipating power as heat. All resistors have a maximum voltage rating. The graphic symbol (based on the new international standards) in the circuit diagram is shown below.

And it's worth noting that the American resistor symbol is also used today. Several common standards include: various resistor symbols, and different countries might use, and different countries might use (1) IEC 60617 (alternatively termed British Standard BS 3939). (2) Additionally, there is IEC 61131-3 for ladder-logic symbols. (3) JIC (Joint Industrial Council) symbols, which are sanctioned and embraced by the NMTBA (National Machine Tool Builders Association).Because of various reasons, the real resistance value is always different from the nominal resistance value.

In the US, MIL-STD-202 contains the relevant test methods to which other standards refer. There are various standards specifying properties of resistors for use in equipment: IEC 60062(IEC 62) /DIN 40825/BS 1852/IS 8186/JIS C 5062etc. (Resistor color code,RKM code, date code)

EIA RS-279/DIN 41429(Resistor color code)

IEC 60063(IEC 63) /JIS C 5063(Standard E series values)

MIL-PRF-26MIL-PRF-39007 (Fixed power, established reliability)

MIL-PRF-55342 (Surface-mount thick and thin film)

MIL-PRF-914MIL-R-11

MIL-R-39017 (Fixed, General Purpose, Established Reliability)

MIL-PRF-32159 (zero ohm jumpers)

UL 1412 (fusing and temperature limited resistors)

There are other United States military procurement MIL-R- standards.The main standard for resistance, known as the "mercury ohm," was first established in 1884 as a column of mercury measuring 106.3 cm in length and 1 square millimeter in cross-section, at a temperature of 0 degrees Celsius.

Importance of Fixed Resistors in Circuits

Fixed resistors are essential elements in electronic circuits, playing vital roles that influence the performance, dependability, and efficiency of numerous devices. The primary function of a fixed resistor is to regulate or restrict the flow of electrical current within an electronic circuit and adjust signal levels. You might think they are just simple electric components with wire leads and maximum voltage rating, however, they have great significance, which can be emphasized through multiple key elements:

1. Current Control and Limiting

The main role of fixed resistors is to regulate and restrict the flow of electrical current in a circuit. By supplying a defined resistance value, they can avert excessive current from harming delicate components, thereby improving the overall durability and lifespan of the electronic system. This is especially crucial in power supply uses, where the resistor lowers the incoming voltage, making sure that following components obtain safe and suitable levels.

2. Voltage Division

Fixed resistors play a crucial role in voltage divider circuits, assisting in generating precise voltage levels for different sections of a circuit. This ability is vital in scenarios where exact voltage levels are needed for biasing DIODES and transistors, establishing the operating point referred to as the Q-point. In this way, fixed resistors allow active components to operate effectively, which is crucial in amplifiers and signal processing systems.

3. Biasing and Stabilization

In linear circuits, stationary resistors are essential for biasing active elements such as transistors and diodes. Their strategic positioning within circuits aids in stabilizing operating conditions and guarantees that devices operate under consistent circumstances. This is especially crucial in analog circuits, where variations in temperature and other environmental elements can influence performance. By keeping a consistent bias point, fixed resistors enhance the circuit's reliability.

4. Noise Reduction

Fixed resistors are often utilized as pull-up or pull-down resistors in digital circuits to avoid floating inputs, which may cause unpredictable behavior from noise and electromagnetic interference. These resistors improve the integrity of digital signals by assigning a specific state (high or low) to inputs while switches are open, resulting in more dependable functioning of logic devices and microcontrollers.

5. Thermal Management

In systems that require heaters or circuits to release large quantities of heat, fixed resistors are used to effectively transform electrical energy into thermal energy. Their capacity to handle heat dissipation is essential for ensuring that components function within safe temperature ranges, thus avoiding overheating and possible failure.

6. Wide Range of Applications

The adaptability of fixed resistors enables their application in various sectors like telecommunications, consumer electronics, automotive systems, and medical equipment. Their capacity to operate efficiently in diverse environmental situations, such as varying temperatures and humidity levels, renders them essential in contemporary electronic design.

7. Simplicity and Reliability

Fixed resistors are simple elements that operate without needing intricate setups or active components. Their durability and dependability over time render them a favored option in numerous applications, providing steady performance without requiring ongoing adjustments.

Construction of a Fixed Resistor

A fixed resistor is made up of two primary parts: the resistive element and the external casing. Let’s explore these two aspects further to grasp the design and operation of fixed resistors.

1. Resistive Element

The resistive component is the heart of a fixed resistor and is accountable for offering resistance to the movement of electric current. Numerous materials and techniques are utilized to produce this resistive component, all closely related to the specific application planned:

Carbon Composition: Historically, the passive component, known as carbon composition resistors, constructed from a blend of carbon black and a binding resin, provided excellent linearity and were simple to produce. These are typically employed in low-frequency applications and in situations where cost is a major concern.

Metal Film: Metal film resistors are made up of a slim layer of metal applied to a ceramic base, which helps to ensure the outstanding stability and temperature coefficients. They are favored in precision applications due to their minimal noise and high precision.

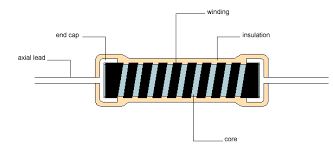

Wire Wound: Wire wound resistors, a kind of passive component, utilize a length of wire wrapped around an insulating core. This type can manage greater power levels and is frequently utilized in situations where power dissipation requires careful oversight. Because wirewound resistors are coils they have more undesirable inductance than other types of resistor.

Thick Film: Thick film resistors are manufactured by employing a screen-printing method to apply a resistive paste onto a substrate. They are frequently encountered in applications that need a balance among cost, size, and performance.

Every type of resistive component has distinct characteristics, including power ratings, tolerance levels, and temperature coefficients, so it is crucial to select the appropriate type according to the particular needs of the circuit.

2. Outer Casing

The external casing is essential for safeguarding the resistive component against environmental influences and guaranteeing safety while in use. The resistor material used for the casing can improve both performance and longevity across different applications:

Plastic: Ideal for low-energy uses, plastic enclosures are affordable and lightweight. Nonetheless, they might struggle with elevated temperatures, potentially restricting their uses.

Ceramic: Commonly utilized for wire wound resistors, ceramic enclosures can endure elevated temperatures while offering outstanding insulation characteristics. They additionally provide enhanced mechanical strength, making them perfect for industrial and high-power uses.

Metal: Metal enclosures are commonly utilized for high-power resistors due to their excellent thermal conductivity and robustness. They might also contribute to the total electromagnetic shielding, safeguarding delicate components from disruption.

The outer casing design might include extra components such as heat sinks or ventilation systems to promote effective heat management, guaranteeing a prolonged lifespan for both the resistor and the complete circuit.

Types of Fixed Resistors

Wire Wound Resistors

The wire-wound resistor is a kind of device created by wrapping a metal wire around a metallic core. The metallic wire serves as the resistive element to the electric current. The metal wire generates the resistance. The metal core serves as the conductive part, although it stops the electric current from passing through it. The wires are usually constructed from nichrome or manganin because of their outstanding ability to resist electric current.

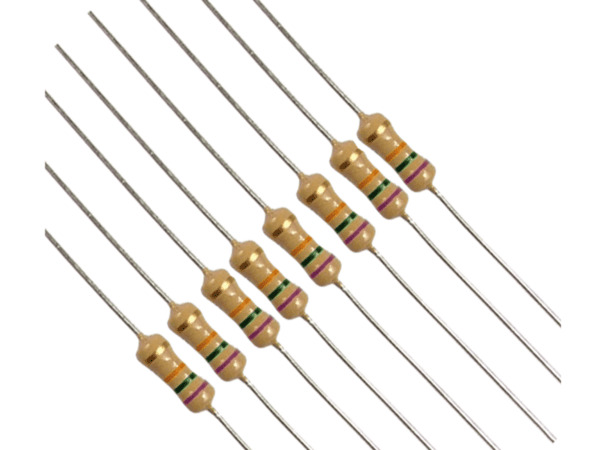

Carbon Composition Resistors

The carbon composition resistor is yet another passive component that restricts the flow of electric current to a certain extent. These consist of cylindrical resistive parts that feature built-in metal end caps. The cylindrical resistive element consists of a mixture of ceramic and carbon powder. This carbon powder has outstanding electrical conductivity properties. These resistors were the most frequently used types in the early 1960s. However, nowadays they are rarely used because of their low stability and high cost.

Carbon Film Resistors

Carbon film resistors are frequently used in electronic circuits. These resistors are produced by coating a ceramic base with a carbon film. The carbon film has resistive properties, establishing it as the main resistive element in these resistors. Conversely, ceramic acts as the insulating material for electric current.

The resistive part has metal end caps fixed to both of its ends. The leads consist of copper and are attached to each end of the end caps. The carbon film resistors operate by producing less noise in comparison to the carbon composition resistors.

When subjected to high temperatures, carbon-film resistors can either lower or raise their resistance. If operated near their maximum dissipation, carbon film and composition resistors may fail (open circuit).

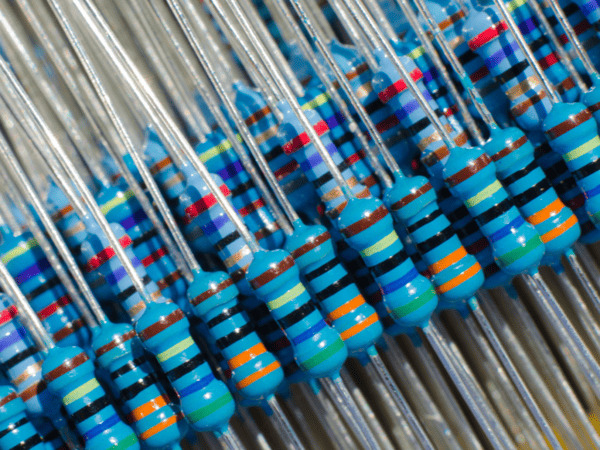

Metal Film Resistors

The metal film resistor is a passive device that uses a metal film to restrict the flow of electric current to a certain extent. They are built in a way similar to carbon film resistors. The main difference is in the resistor element used in the film's creation. The film consists of metal to control the electric current.

Metal film resistors show a minimal temperature coefficient of resistance. The rate at which the resistance of a material varies with rising temperature is known as TCR.

Metal Oxide Film Resistors

The materials used to form the resistive film consist of metal oxide, such as tin oxide. Their design is similar to that of metal film resistors, except for the type of material used for the film. These metal oxide film resistors are less expensive than carbon composition resistors. Besides, metal oxide film resistors are known for operating at high temperatures, be beneficial due to long-term stability.

Metal Glaze Resistors

This resistor utilizes a mixture of metallic particles and glass powder to restrict the flow of electric current to a specific extent. These resistors show a reduced TCR, known as the temperature coefficient of resistance. From TCR, we can see that when the temperature increases, the resistance of the material will also change. Metal glaze resistors are commonly employed in nuclear apparatus, infrared image converters, communication systems, navigational radars, particle accelerators, voltage dividers, and other applications.

Foil Resistors

Foil resistors are the most precise and dependable components utilized to restrict current flow. These resistors generate less noise in comparison to other types of Fixed Resistors. An alternative name for foil resistors is high-precision resistors, which have a reduced TCR. They made use of audio components, oil seals, aviation, electronics marketing, and additional sectors.

Difference Between a Fixed Resistor and a Variable Resistor

What is a Variable Resistor?

Variable resistors are commonly utilized in electrical circuits to modify the level of current or voltage, as the resistance of variable resistors can be adjusted to a specific value. Variable resistors enable the adjustment of voltage levels by altering the resistance while maintaining a constant current.

A representation of a conventional variable resistor symbol, which illustrates the concept of resistance modification and its real connection in the circuit, is displayed where the wiper pin attaches to one of the fixed pins, effectively bypassing a portion of the resistive element to change the resistance value. In case of variable resistors, we use a single resistor for different resistance values. A variable resistor is used in dimmers or volume controls.

Types of Variable Resistors

Potentiometer

Potentiometers, commonly known as "pots," allow for precise adjustment of resistance through a dial or sliding mechanism. The resistive component of a potentiometer is adjustable via a wiper that is operated by turning a knob. In addition to the “wiper” terminal, potentiometers possess two extra terminals, commonly known as “input” and “output” terminals. There are two typical varieties of potentiometers: linear and rotary. Linear potentiometers are utilized in functions like volume adjustment for audio equipment, whereas rotary potentiometers are used in scenarios that demand rotational modification, such as adjusting radio frequencies. They exist in different types, such as carbon film and metal oxide versions.

Rheostat

Rheostats are specific variable resistors created with just two terminals. Potentiometers are utilized for voltage control, whereas rheostats are mainly employed to regulate current in a circuit, modifying electrical resistance as required. The two terminals are linked in series with a load (for example, a light bulb or motor). Modifying the wiper's position on the resistance wire alters the resistance in series with the load, thereby regulating the current. Typical uses of rheostats consist of dimmer switches for lighting and controlling motor speed.

Photo Resistor

Photo resistors, commonly referred to as light-dependent resistors (LDRs), are non-linear resistors with two terminals that vary according to intensity of light. An LDR shows a reduction in resistance when light intensity rises, allowing it to detect and respond to changes in ambient light conditions. This characteristic makes an LDR perfect for uses such as automated lighting control and light-sensitive alert systems.

Wirewound Resistor

Wirewound resistors, made by coiling a resistive wire around an insulated core, are recognized for their accuracy and capability to manage high power capacities. Despite featuring both fixed and variable options, variable wirewound resistors enable modifications to the length of the resistance wire in the circuit, thus changing the resistance. Wirewound resistors additionally feature two terminals. Wirewound resistors are utilized in situations that require exact resistance values, like in precision devices and high-power electronic systems.

Wirewound resistors are available in both precision and high-power options. Precision wirewound resistors provide high accuracy and minimal tolerance, making them ideal for uses such as voltage dividers and precision amplifiers. Power wirewound resistors are designed to endure elevated power levels, ensuring they retain their resistance value in tough situations, making them ideal for high-current circuits and power amplifiers.

Thermistor

Thermistors are resistors sensitive to temperature, featuring two terminals that show variations in electrical resistance due to temperature changes. They are categorized into two main types: negative temperature coefficient (NTC) and positive temperature coefficient (PTC). NTC thermistors lower their resistance as temperature rises or current increases, whereas PTC thermistor resistance increase with increase in temperature, rendering them crucial in temperature regulation systems like thermostats and important for temperature compensation in multiple electronic circuits.

Varistor

Varistors, referred to as voltage-dependent resistors or VDRs, are unique two-terminal adjustable resistors intended to shield electronic circuits from voltage spikes and surges. They demonstrate significant electrical resistance in standard conditions but quickly lower their resistance when subjected to high level of voltage. This action enables varistors to divert excessive voltage from delicate components by permitting a high current to pass through the varistor instead. Varistors are utilized for surge protection in electronic systems.

|

Fixed Resistor |

Variable Resistor |

|

Possesses a constant resistance value. |

Has a resistance value that changes. |

|

Displays its values on its surface, making it unchangeable. |

Allows for value adjustments since their values are not marked. |

|

Comes in various types, including thin film, thick film, surface mount, wire wound, metal film chip, and metal oxide resistors. |

Available in three types trimmer, potentiometer, and rheostat. |

|

Includes two terminals that are used to connect different components in a circuit. |

Consists of three terminals, with two fixed and one movable terminal known as the wiper. |

|

Crafted using either manganin wire or nichrome wire for winding the core due to their high resistance, while glass, ceramic, or plastic are utilized for the core itself. |

Features a resistance track constructed from carbon, cermet, or a wire coil. |

|

Limits the current passage in a circuit to a specific level. |

Utilized to control the voltage or current levels in a circuit. |

|

Utilized in amplifiers, television sets, and other expensive electronic circuits. |

Utilized in a dimmer switch for lighting and the dial for adjusting volume on a radio. |

|

The resistance ratings primarily consist of 10Ω, 100Ω, 10kΩ, and 100KΩ. |

The resistance values of variable resistors vary from 0 to a specific maximum value. |

The Advantages and Disadvantages of Fixed Resistors

Advantages:

1.Reduced Expense—high-performance and high-power carbon film resistors are affordable.

2. Low Noise—carbon film resistors produce lower noise levels in comparison to other resistor types.

3. Compact Size—carbon film resistors, especially thick film and thin-film varieties, are smaller in comparison to other resistor types.

4. High Stability—carbon film resistors exhibit greater stability compared to metal oxide resistors as they remain unaffected by variations in temperature and humidity.

Disadvantages:

1. Low Power Rating – carbon film resistors possess low power ratings. The highest power rating is typically 1/8 watt or lower.

2. Reduced Precision—carbon film resistors lack the accuracy found in metal oxide resistors or wire wound resistors.

3. Constant Resistance Value – Resistance values cannot be modified after the resistors are produced.

They aren't waterproof and cannot be utilized beneath the water.

They can endure a maximum of 1 volt per second.

They are susceptible to noise and disturbances, particularly when there is a significant amount of electromagnetic radiation present, because of their low resistance.

The Application of Fixed Resistors

The uses are listed as follows.

They are utilized in power supplies to lower the incoming voltage, can also serve in circuits to restrict the flow of current, and are employed in heaters that require heat energy dissipation.

Fixed resistors are frequently employed for biasing diodes and transistors, indicating that they are utilized to establish the operating point (also referred to as Q-point) of active components like diodes and transistors.

The fixed resistor can be positioned at different locations within the circuit, depending on its intended impact on the circuit's overall function.

They are often employed as pull-up resistors in digital circuits since they assist in stopping floating inputs from altering state because of noise or other disturbances. You can also see them in ampere meters.

Real World Examples of Fixed Resistors

Utilization of Resistors in Circuit Operations

There are different kinds of resistors that operate based on their application range. In that, we can adjust the resistance through a knob-like mechanism. Altering resistance will impact the current flow within the circuit. For instance, this kind of resistor is employed in regulating motor speed, pitch of a musical note, volume of an amplifier, and so on.

A resistor is employed for reducing voltage.

Splitting the voltage is effective when certain components require operation at a significantly lower voltage than the input voltage provided. Joining the resistors in series will aid in evenly distributing the voltage across each resistor, thereby supporting the appliances that operate under those conditions.

Heating

Due to the heat produced when electricity flows, resistors are utilized in devices such as heaters, toasters, microwaves, electric stoves, and numerous other heating appliances. Inside a light bulb, the metal filament shines white-hot because of the extremely high operating temperature generated by the resistance as electricity flows through it.

Applications of a Resistor to operate at specific Timing and a defined Frequency

Similar to a light flasher, electronic sirens, and blinking lights found on airplanes or tall structures that serve as a collision prevention mechanism. They operate based on the principle of storing current for a specific duration and then emitting light; in this case, the resistor determines the amount of current to be allowed based on the designated time. If resistance rises, the duration for the current to discharge in the circuit lengthens.

Resistors employed in LEDs and Transistors

Excessive current flowing through a LED or transistors can be hazardous as they are highly sensitive to electric current. Utilizing a resistor in the circuit will benefit the LEDs, transistors, and other types of semiconductors to function in the desired current range ideal for them.

Opportunities for Fixed Resistors

Numerous types of resistors are currently available in the market, yet the sector for fixed resistors presents significant growth opportunities, driven by the increasing focus on energy efficiency and the adoption of renewable energy options. The growing awareness of energy conservation and the need to reduce carbon emissions has led to the use of energy-efficient electronic devices and systems. Fixed resistors are essential in regulating electric current flow and enhancing the energy efficiency of electronic circuits. Producers can take advantage of this chance by creating sophisticated resistors that feature minimal power usage and high accuracy.

The increasing use of renewable energy sources, like solar and wind energy, offers another encouraging chance for the fixed resistor market. Renewable energy systems depend on dependable and efficient components to guarantee their correct operation and effectiveness. Fixed resistors find applications in renewable energy systems for tasks such as power conversion, energy storage, and grid integration. The rising investments in renewable energy infrastructure and the heightened emphasis on sustainable energy solutions are anticipated to boost the demand for fixed resistors in this field.

Why Unikey is a Good Choice?

In the realm of obtaining top-notch fixed resistors, Unikey emerges as an outstanding option for various persuasive reasons. As a globally acknowledged authorized distributor and supplier, Unikey focuses on high-quality electronic components such as Fixed Resistors. The firm provides a wide selection of products, such as active devices, passive devices, discrete components, connectors, and others, featuring an inventory that exceeds 150,000 unique items. Well-known in the electronic components sector, Unikey is dedicated to quality, innovation, and customer satisfaction. The properties of production resistors are assessed and categorized based on different national standards.

Here are some key reasons why Unikey is a favored source for fixed resistors.

1. Superior Quality and Reliability

Unikey takes pride in the excellence of its products. The firm implements strict quality assurance practices at every stage of its production process. This dedication to quality guarantees that their fixed resistors meet or surpass industry standards, offering clients dependable components that work uniformly across different applications. By selecting Unikey, clients can rely on the fact that their electronic designs will be improved with components that boost functionality and durability.

2. Diverse Product Range

Unikey provides a diverse selection of fixed resistors, accommodating different specifications and uses. This variety enables customers to locate the appropriate resistor for their particular requirements, whether they need precision resistors for medical equipment or high-power resistors for renewable energy uses. Unikey’s wide array of offerings makes it a comprehensive resource for developers and engineers in search of customized electronic solutions.

3. Advanced Technology and Innovation

In the continuously changing electronics field, keeping up with technological progress is essential. Unikey allocates resources for research and development to incorporate advanced technology into their production methods. Consequently, the firm's fixed resistors are engineered with exceptional accuracy, minimal noise, and improved thermal stability, rendering them ideal for the most challenging applications. This commitment to innovation establishes Unikey as a leader in the market.

4. Excellent Customer Support

Unikey recognizes that delivering excellent products is just one aspect; outstanding customer service holds equal significance. The company takes pride in providing attentive and informed assistance to aid clients in their decision-making journey. Whether offering technical guidance or helping with custom orders, Unikey's customer service team guarantees that clients obtain the support necessary to make informed choices.

5. Competitive Pricing

Although quality is a primary focus, Unikey also understands the significance of affordability in the current competitive landscape. The company aims to provide competitive prices while maintaining product reliability. Unikey assists businesses in optimizing their budgets by offering high-quality fixed resistors at reasonable prices, ensuring access to premium electronic components.

6. Commitment to Sustainability

In keeping with worldwide movements toward sustainability, Unikey is committed to eco-friendly methods in its manufacturing processes. The firm diligently strives to reduce waste and energy usage, guaranteeing that its activities benefit the environment. This dedication not only attracts environmentally aware businesses but also promotes the broader sustainability objectives of the industry.

Conclusion

The symbol for a fixed resistor is a basic depiction in the realm of electronics, showcasing the essential function these elements serve in circuit design. Usually represented as a basic rectangle in schematic diagrams, this symbol not only indicates a fixed resistor's opposition to electric current flow but also helps to clarify intricate circuit illustrations.

Fixed resistors are defined by their capacity to keep a steady resistance value, regardless of variations in voltage or current. This dependability is crucial for consistent electrical operation in multiple uses, from simple electronics to advanced electronic equipment. Comprehending the symbol and role of fixed resistors enables both engineers and enthusiasts to create efficient and dependable circuits.

Additionally, the adaptability of fixed resistors renders them essential for a range of applications, such as voltage regulation, current limiting, and signal conditioning. Their existence in both analog and digital circuits highlights their essential significance in electrical engineering.

With technological progress, the materials and techniques employed in the production of fixed resistors also evolve. Contemporary advancements in materials science lead to better performance traits, including reduced noise and enhanced thermal stability, which are vital for high-precision uses.

To sum up, identifying the symbol of a fixed resistor is merely the first step toward grasping its considerable influence in the field of electronics. Dedicated to innovation and sustainability, upcoming advancements in fixed resistor technology will keep influencing the industry, allowing for more efficient and eco-friendly solutions. Regardless of whether you are an experienced engineer or an inquisitive learner, mastering this fundamental yet vital symbol will improve your understanding of electronic circuit design and inspire further investigation into the intriguing realm of electrical components.