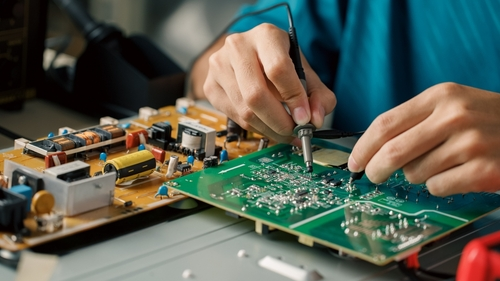

Storage of Parts of Electronic Components: Best Practices and Key Considerations

The storage of parts of electronic components is a critical aspect of inventory management for both electronic equipment manufacturers and electronic component suppliers. Whether you are managing a warehouse stocked with essential components for production or operating a distribution center, effective storage practices are vital. Improper storage can lead to component degradation, loss, or damage, resulting in financial losses and production delays. This article will explore the best practices for storing parts of electronic components, highlighting key considerations and strategies to maintain the integrity and functionality of these vital parts.

Importance of Proper Storage in Parts of Electronic Components

Before diving into specific storage tips, it's important to understand why proper storage of electronic component parts is essential. Electronic components are sensitive to various environmental factors such as moisture, temperature fluctuations, and electrostatic discharge (ESD). Even small changes in these conditions can compromise component performance, leading to failures in the final product. Additionally, many electronic components are small, delicate, and expensive, making inventory management a challenge. Thus, ensuring that the storage environment is carefully controlled is key to maintaining product quality and avoiding costly errors.

1. Controlling Air Humidity: Protecting Against Moisture Damage

Humidity control is one of the most crucial aspects of storing electronic components. Moisture can cause significant damage, leading to oxidation, corrosion, and short circuits. To effectively store parts of electronic components, it’s important to:Install Ventilation Systems: Whether your warehouse is located above ground or in a basement, having a reliable ventilation system is crucial. It helps regulate humidity levels and prevents moisture from accumulating. High humidity can lead to oxidation of metal components, which can degrade performance and render the parts unusable.Use Dehumidifiers and Moisture-Absorbent Materials: In regions with high humidity, installing dehumidifiers and using moisture-absorbent materials like silica gel can help maintain optimal humidity levels. Ideal relative humidity levels for storing electronic components typically range between 30% and 50%.

Implement Humidity-Controlled Storage Areas: For especially sensitive parts, consider using humidity-controlled cabinets or dry storage boxes. These enclosures provide a stable environment with low humidity, preventing any moisture-related damage.

2. Hiring Professional Warehouse Managers: Avoiding Mismanagement and Loss

The diversity of parts in electronic components warehouses, coupled with their small size and high value, makes proper organization and management essential. Employing professional warehouse managers ensures that components are accurately categorized, stored, and tracked. Here’s how skilled warehouse management can benefit your operations:Inventory Organization: Professional managers use standardized systems for labeling, categorizing, and storing electronic components. This reduces the chances of misplacing or losing valuable parts, which can cause inventory discrepancies and financial loss.Tracking and Documentation: A well-managed warehouse keeps detailed records of each component’s movement, from the moment it enters the warehouse to when it is dispatched. Using inventory management software integrated with barcode or RFID systems improves accuracy and efficiency in tracking.

Component Identification and Handling: Properly trained personnel are essential for handling delicate components, reducing the risk of damage. They are also knowledgeable in identifying and managing the unique requirements of different types of electronic parts, ensuring that sensitive components are given the appropriate storage conditions.

3. Enhancing Warehouse Management: Detailed Record-Keeping and Monitoring

Strengthening warehouse management practices is essential, especially as the volume of stored components increases. Improved management helps prevent issues such as loss, damage, or mismanagement. Here are some key practices:Implement a Robust Inventory Management System: A digital inventory system that tracks each part of electronic components is essential. The system should log details such as part number, quantity, location within the warehouse, and storage conditions. Regular audits and inventory checks ensure data accuracy and help detect any discrepancies early.Document Every Movement: Whether new parts are being stored or existing parts are being retrieved for production or shipping, it’s important to document every step. This includes noting the time, date, personnel involved, and any other relevant details. Keeping photos of labels, models, and part numbers can help resolve any potential disputes or issues related to order accuracy.

Use FIFO (First In, First Out) Methodology: For components with limited shelf life or susceptibility to degradation over time, it’s important to follow the FIFO methodology. This ensures that older stock is used before newer stock, reducing the chances of components expiring in storage.

4. Fire Prevention: Ensuring Safety in Electronic Component Storage

Fire prevention is a critical consideration when storing parts of electronic components. Many materials used in electronics, such as plastics and certain chemicals, are flammable. Here’s how to minimize fire risks:Implement Comprehensive Fire Safety Measures: Ensure that your warehouse is equipped with fire alarms, sprinkler systems, and fire extinguishers. Regular fire safety drills and training for staff are essential to prepare for emergencies.Monitor Storage Conditions: Overcrowded storage, improper ventilation, and exposure to high temperatures can increase the risk of fire. Make sure that components are stored with adequate spacing to allow air circulation and prevent overheating.

Global Distribution and Redundancy: For larger electronic component suppliers, it’s wise to have multiple storage locations across different regions. In the event of an accident or fire at one location, operations can continue using components from other warehouses, minimizing disruption.

5. Ensuring Electrostatic Discharge (ESD) Protection

Electrostatic discharge (ESD) can severely damage sensitive electronic components. Implementing ESD protection measures is a critical part of managing electronic components. Here’s how you can safeguard your inventory:ESD-Safe Flooring and Workstations: Install ESD-safe flooring and equip workstations with grounded mats and wrist straps to prevent the buildup of static electricity.Use ESD-Protective Packaging: Store components in ESD-safe bags, tubes, or containers that shield them from electrostatic discharge. Proper packaging is especially important during transit.

Train Staff on ESD Precautions: Ensure that all warehouse personnel are trained in ESD handling procedures. Even minor electrostatic discharges can cause latent damage that may only become apparent once the component is integrated into a device.

6. Temperature Control: Preventing Thermal Damage

Electronic components are sensitive to temperature fluctuations. High temperatures can lead to component degradation, while low temperatures can cause condensation, leading to moisture damage. Here are some tips for temperature management:Maintain Stable Temperatures: Keep storage areas at consistent temperatures, ideally between 15°C and 25°C (59°F to 77°F), depending on the type of components stored. Avoid placing components near heat sources or in direct sunlight.Monitor and Record Temperature: Use temperature sensors to continuously monitor conditions within the storage area. Automatic alerts can notify management if temperatures fall outside the desired range.

Separate Temperature-Sensitive Components: Some components require stricter temperature controls. Store these items in specialized climate-controlled areas or refrigeration units if necessary.

7. Benefits of Digital Transformation in Electronic Component Storage

The shift toward digital transformation in warehouse management has brought significant improvements to the storage and distribution of parts of electronic components. Digital tools streamline processes, reduce human error, and enhance inventory visibility. Here’s how digitization benefits electronic components manufacturing:Real-Time Inventory Tracking: Digital systems provide real-time updates on stock levels, helping prevent shortages or overstocking. Advanced analytics can forecast demand trends and optimize reordering schedules.Automation and Efficiency: Automation tools such as robotic storage systems and automated guided vehicles (AGVs) can efficiently manage large inventories, reducing the time required to retrieve or store components.Enhanced Customer Experience: Digital transformation enables suppliers to provide accurate delivery estimates, real-time order tracking, and better communication with customers.

unikeyic Electronics has leveraged digital advancements to become a leading player in the electronic components manufacturing industry, offering seamless procurement experiences for businesses worldwide.

Conclusion: Strengthening Storage Practices for Optimal Component Quality

Effective storage of parts of electronic components requires careful attention to factors such as humidity control, ESD protection, temperature management, and fire safety. By adopting best practices and leveraging digital tools, electronic equipment manufacturers and component suppliers can ensure the quality, reliability, and longevity of their inventory.Choosing a reliable partner like Unikeyic Electronics, an industry leader in electronic components manufacturing, offers you access to quality products, cutting-edge inventory management solutions, and comprehensive technical support. By adhering to these storage practices, you can minimize risks and maintain the integrity of your valuable electronic components, ultimately ensuring smooth production processes and high-quality end products.

Related electronic components articles recommended

The Best Place to Buy Electronic-Components OnlineUnikeyic Electronics Supply Chains with Authorized Distributors of Electronic-ComponentsFinding the Right Electronic-Components Shop Near Me – Your Guide to Convenient Shopping and Reliable ServiceTop Suppliers for IC Electronic-Components: Where to Buy Quality PartsProcess for sourcing parts from electronic-components parts store near meBulk Electronic-Components: How to Handle Logistics and StorageExploring the Leading Electronic-Components Shops in Singapore