Silicon Carbide Field Effect Tubes: Revolutionizing Power Electronics

Introduction to Silicon Carbide Technology

Silicon Carbide Field Effect Tube is a semiconductor material that has gained significant traction in the field of power electronics. This popularity stems from its unique properties, which make it exceptionally suitable for high-performance applications. Unlike traditional silicon, SiC boasts higher thermal conductivity, wider bandgap, and greater breakdown voltage. These characteristics enable SiC devices to operate at higher temperatures and voltages, making them ideal for demanding environments where efficiency and reliability are paramount.

Comparison with Traditional Materials

When comparing Silicon Carbide Field Effect Tubes (SiC FETs) with traditional silicon FETs, the advantages of SiC become evident. SiC FETs exhibit superior efficiency, particularly in high-voltage and high-frequency applications. This efficiency translates to reduced energy losses, which is crucial in applications like electric vehicles (EVs) and renewable energy systems.

Advantages of Silicon Carbide Field Effect Tube Higher Efficiency

Silicon Carbide (SiC) Field Effect Tubes (FETs) offer significantly higher efficiency compared to traditional silicon FETs. This efficiency stems from their ability to handle higher power densities, which means they can transmit more power with less energy loss. In practical terms, this translates to lower heat generation during operation. The reduction in heat loss not only enhances the overall performance of electronic systems but also allows for longer operational lifespans of components. This is particularly beneficial in high-demand applications, such as electric vehicles and renewable energy systems, where efficiency directly impacts performance and energy savings.

Improved Thermal Performance

SiC's inherent material properties provide superior thermal performance. SiC can operate effectively at much higher temperatures than silicon, typically up to 200°C or more, compared to silicon’s limit of around 150°C. This capability allows designers to create more compact systems without extensive cooling requirements. Reduced cooling needs mean less bulk and weight, leading to lighter and smaller designs, which is crucial in applications like automotive industries where space and weight are at a premium. Additionally, the improved thermal performance minimizes the risk of thermal runaway, enhancing the reliability of electronic systems.

Greater Power Density

Another significant advantage of SiC FETs is their ability to achieve greater power density. SiC devices can switch at higher speeds, often exceeding the capabilities of silicon devices. This high switching frequency enables designers to implement smaller passive components, such as inductors and capacitors, which are essential for filtering and energy storage. As a result, power electronic systems can be made more compact and efficient, reducing the overall size and weight of power converters and inverters.

The ability to switch faster also leads to improved overall system responsiveness, making SiC FETs particularly valuable in applications requiring quick modulation of power, such as in motor drives and power supplies. This increased power density allows for innovative designs that maximize performance while minimizing footprint and weight, further driving the adoption of SiC technology across various industries.

Applications of Silicon Carbide Field Effect Tube

SiC FETs find applications across various industries, demonstrating their versatility and effectiveness. Here are some notable sectors leveraging this technology:Renewable Energy: In solar inverters, SiC FETs contribute to higher efficiency and compact designs, allowing for better energy conversion and reduced space requirements.

Electric Vehicles: SiC technology enhances the performance of EV powertrains by improving the efficiency of the inverter systems, resulting in longer driving ranges and faster charging times.

Industrial Motor Drives: SiC FETs are used in motor control applications where high efficiency and thermal management are essential, driving down operational costs.

Technical Characteristics

Understanding the technical specifications of SiC FETs is crucial for selecting the right component for specific applications. Key characteristics include:Voltage Ratings: SiC FETs can operate at higher voltage levels, often exceeding 1,200 volts, making them suitable for high-power applications.

Current Handling Capabilities: They support higher current levels, which is beneficial in applications demanding robust power handling.

Switching Speeds: SiC FETs can switch at much higher speeds compared to silicon counterparts, enabling faster operation and greater efficiency.

Thermal Performance: With better thermal conductivity, SiC devices can manage heat more effectively, which is critical in high-power applications.

These characteristics are essential in real-world applications, ensuring that the devices perform optimally under various conditions.

Market Trends and Growth

The market for SiC technology is witnessing substantial growth, driven by several factors:Demand for Energy Efficiency: As industries strive to reduce energy consumption, the adoption of SiC FETs is on the rise due to their superior efficiency.

Transition to Electric Vehicles: The global shift towards electrification in the automotive sector has significantly increased the demand for SiC components, as they enable better performance in EV applications.

This trend indicates a bright future for SiC technology, with continued investment in research and development.

Challenges and Considerations

Despite their advantages, there are challenges associated with using SiC FETs:Cost: SiC devices tend to be more expensive than traditional silicon options, which can be a barrier for some applications.

Availability: Sourcing SiC components can sometimes be challenging due to the limited number of manufacturers.

Driver Circuitry: Designing circuits to accommodate SiC FETs may require specific driver solutions, which adds complexity to the design process.

Engineers must carefully consider these factors when designing with SiC technology to ensure successful implementation.

Future Developments in SiC Technology

The future of Silicon Carbide technology is promising, with several potential advancements on the horizon:Innovations in Manufacturing: As production processes improve, the cost of SiC devices is expected to decrease, making them more accessible for a wider range of applications.

Enhanced Performance: Ongoing research aims to further enhance the performance characteristics of SiC FETs, leading to even greater efficiency and reliability.

These developments will continue to shape the power electronics landscape, making SiC a key player in future technologies.

Buying Guide for Silicon Carbide Field Effect Tube

When selecting the right Silicon Carbide Field Effect Tube (SiC FET) for your application, it's crucial to make informed decisions. Here are some essential tips to guide you through the purchasing process:

1. Assess Your Requirements

Before diving into the selection process, clearly define your project's requirements. Consider the following factors:Voltage Rating: Determine the maximum voltage your application will require. SiC FETs come in various voltage ratings, and selecting one that matches or exceeds your requirements is essential to avoid component failure.

Current Rating: Understand the current your application will draw. Ensure that the selected SiC FET can handle the necessary current without overheating or becoming inefficient.

Thermal Performance: Assess the thermal conditions under which the SiC FET will operate. Look for devices with higher thermal conductivity and operating temperature ratings, as these will enhance performance and reliability in demanding applications.

2. Research Reputable Suppliers

Once you have a clear understanding of your requirements, research suppliers that specialize in SiC technology. It's vital to choose reputable distributors known for their quality products and excellent customer service. One such trusted distributor is unikeyic Electronics, which offers a wide range of Silicon Carbide FETs from recognized brands like:Microchip Technology: Known for its extensive portfolio of reliable semiconductor products, Microchip's SiC FETs are designed for high efficiency and robustness.

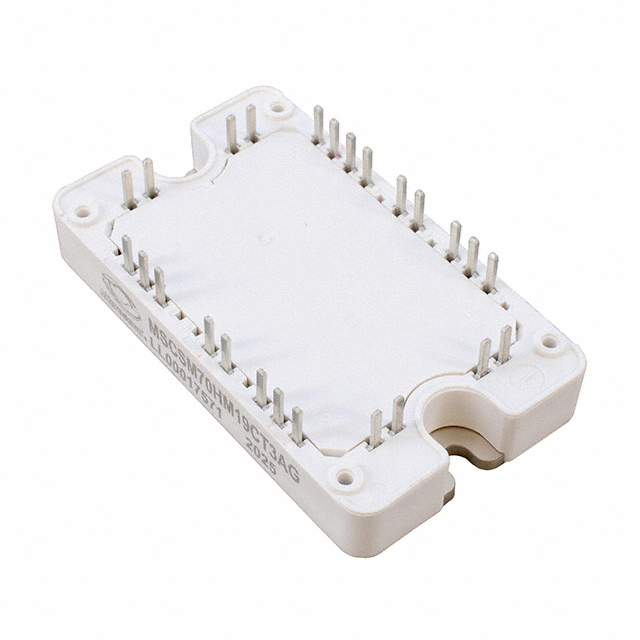

Figure 1: Microchip Technology

Wolfspeed: A leader in SiC technology, Wolfspeed provides advanced power devices that excel in performance and thermal management, making them ideal for high-performance applications.

GeneSiC Semiconductor: Specializing in high-voltage and high-efficiency SiC products, GeneSiC's offerings are suitable for a variety of demanding environments.

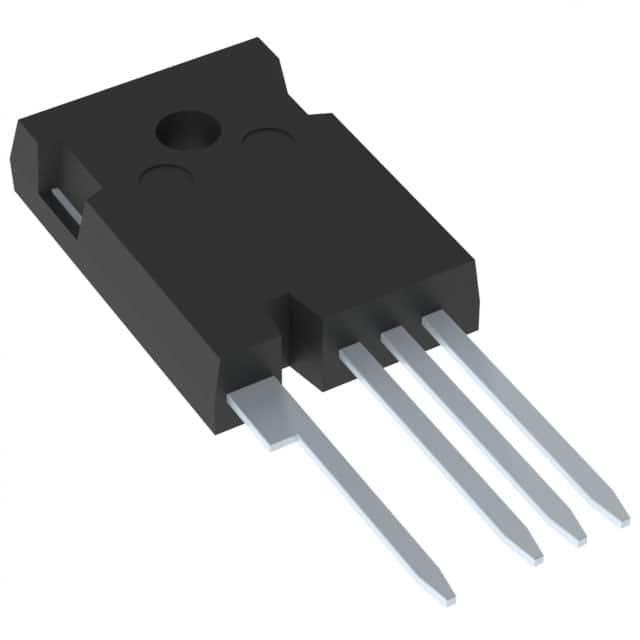

Figure 2: GeneSiC Semiconductor

3. Compare Products

After identifying potential suppliers, take the time to compare the specifications and pricing of different SiC FETs. Key aspects to evaluate include:

Performance Characteristics: Look at switching speeds, on-resistance, and thermal ratings to determine which product best fits your needs. Performance characteristics can vary significantly between manufacturers, so it's essential to make comparisons.

Pricing: While quality should always come first, cost is also a consideration. Check if the supplier offers competitive pricing, discounts for bulk purchases, or special promotions that can help fit your budget.Warranty and Support: Ensure that the products come with a warranty and consider the level of customer support provided by the distributor. Reliable support can be invaluable, especially during the integration and testing phases of your project.

In summary, when selecting the right SiC FET for your application, it’s crucial to assess your specific requirements, research reputable suppliers, and compare products thoroughly. Unikeyic Electronics stands out as a leading distributor of Silicon Carbide Field Effect Tubes, providing both wholesale and retail options for various high-quality brands. By following these tips, you can confidently choose the right SiC FET that will meet your project needs and contribute to the success of your designs.

FAQs about Silicon Carbide FETs

1. What are Silicon Carbide Field Effect Tubes?Silicon Carbide Field Effect Tubes are high-performance semiconductor devices that utilize SiC material to handle high voltages and currents efficiently.

2. How do SiC FETs compare to traditional silicon FETs?SiC FETs generally offer higher efficiency, better thermal performance, and greater power density compared to traditional silicon FETs.

3. Are SiC FETs cost-effective?While SiC FETs may have a higher initial cost, their efficiency and performance can lead to long-term savings, especially in high-power applications.

4. Where can I buy Silicon Carbide FETs?

You can purchase Silicon Carbide FETs from reputable suppliers like Unikeyic Electronics, which offers a wide range of brands and products.

Conclusion

Silicon Carbide Field Effect Tubes are transforming the landscape of power electronics with their superior performance and efficiency. As industries increasingly adopt this technology, understanding its benefits, applications, and challenges becomes essential. Whether you are an engineer, a manufacturer, or a hobbyist, exploring SiC technology can provide significant advantages in your projects. For sourcing high-quality SiC FETs, Unikeyic Electronics is your go-to partner, offering a diverse range of products from trusted brands.