How SMT PCBA Manufacturing is Transforming the Electronics Industry

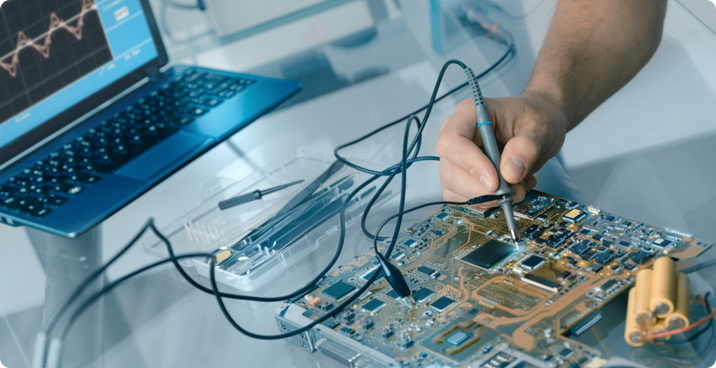

Introduction to SMT and PCBA Manufacturing

Surface Mount Technology (SMT) is a method of producing electronic circuits in which components are mounted directly onto the surface of printed circuit boards (PCBs). SMT revolutionized electronics manufacturing by allowing for more compact, efficient, and cost-effective production compared to the older through-hole technology.

Printed Circuit Board Assembly (PCBA) refers to the process of assembling electronic components on a PCB. This process is crucial in creating functional electronic devices used across various industries. The integration of SMT into PCBA has played a pivotal role in advancing modern electronics manufacturing, enabling the production of smaller, more powerful devices.

The SMT Manufacturing Process

The SMT manufacturing process consists of several key stages, each critical to ensuring the final product's quality and functionality:Solder Paste Application: The process begins with applying solder paste onto the PCB pads. This paste serves as an adhesive to secure the components during placement and as a conductive material to create electrical connections.

Component Placement: Using high-precision pick-and-place machines, electronic components are accurately positioned onto the solder-pasted PCB. These machines can place thousands of components per hour, significantly speeding up production.

Reflow Soldering: The PCB is then passed through a reflow oven, where the solder paste is melted and solidified, forming permanent bonds between the components and the PCB.

Inspection: Finally, the assembled PCBs undergo thorough inspection to ensure quality. This stage involves Automated Optical Inspection (AOI) to check for defects and misalignments and X-ray inspection to assess solder joints and internal structures.

Advantages of SMT in PCBA Manufacturing

SMT offers several advantages over traditional through-hole technology, including:Miniaturization: SMT allows for the placement of smaller components on both sides of the PCB, leading to more compact designs and reducing the size of electronic devices.

Improved Performance: The shorter connections in SMT reduce parasitic inductance and capacitance, enhancing the performance of high-frequency circuits.

Cost-Effectiveness: SMT reduces the need for drilling holes in PCBs, lowering manufacturing costs. The automation of SMT processes also decreases labor costs and increases production efficiency.

Higher Component Density: SMT enables higher component density, allowing for more complex circuit designs and advanced functionalities in electronic products.

Challenges in SMT PCBA Manufacturing

Despite its advantages, SMT PCBA manufacturing presents several challenges:Solder Defects: Issues like solder bridging, voids, and insufficient solder can affect product reliability.

Component Misalignment: Precise placement is crucial; misalignment can lead to electrical failures.

Thermal Management: SMT devices often generate heat that must be effectively dissipated to prevent overheating.

Strategies to overcome these challenges include using advanced solder paste formulations, implementing precise placement techniques, and utilizing thermal management solutions such as heat sinks and fans.

Quality Control and Testing in SMT Manufacturing

Quality control is vital in SMT PCBA manufacturing to ensure the reliability and performance of electronic products. Common testing methods include:Automated Optical Inspection (AOI): AOI systems use cameras and image processing to detect defects in solder joints and component placement.

X-ray Inspection: X-ray systems provide detailed views of solder joints and hidden components, helping identify defects not visible to the naked eye.

In-Circuit Testing (ICT): ICT involves checking electrical connections and functionality, ensuring each component performs as expected.

Technological Innovations in SMT Manufacturing

Recent advancements in SMT manufacturing have further enhanced efficiency and quality:Robotics and Automation: The use of robotics has streamlined the production process, reducing human error and increasing precision.

Industry 4.0: The integration of IoT and AI technologies in manufacturing processes has enabled real-time monitoring and data analysis, optimizing production and maintenance.

Applications of SMT PCBA in Various Industries

SMT PCBA plays a crucial role across multiple industries:Consumer Electronics: Used in smartphones, laptops, and home appliances, SMT PCBA enables compact designs and advanced functionalities.

Automotive: Critical for vehicle electronics such as infotainment systems, engine control units, and advanced driver-assistance systems.

Telecommunications: Facilitates high-speed data transmission in networking equipment and mobile communication devices.

Design Considerations for SMT PCBA

Successful SMT PCBA design involves careful planning and collaboration:Layout Considerations: Efficient PCB layout maximizes space and performance while minimizing interference and heat buildup.

Component Selection: Choosing the right components based on size, power requirements, and functionality is crucial.

Collaboration: Close collaboration between design engineers and manufacturing teams ensures manufacturability and functionality.

Selecting an SMT PCBA Manufacturer

Choosing the right SMT PCBA manufacturer is vital for quality and reliability:Expertise: Look for manufacturers with extensive experience and expertise in SMT PCBA production.

Technology Capabilities: Ensure the manufacturer has advanced equipment and capabilities to handle your specific requirements.

Quality Standards: Verify that the manufacturer follows industry standards and certifications for quality assurance.

Partnering with experienced manufacturers like unikeyic Electronics can provide customized electronic product solutions and technical services, ensuring seamless integration from design to production.

Cost Considerations in SMT PCBA Manufacturing

Understanding the cost factors involved in SMT PCBA manufacturing is essential for budgeting:Materials: Component costs vary based on quality, brand, and availability.

Labor and Equipment: Automation reduces labor costs, but equipment investment is necessary.

Strategies: Implementing cost-saving measures such as bulk purchasing and efficient design can optimize expenses without compromising quality.

Environmental and Sustainability Aspects of SMT Manufacturing

Sustainability is becoming increasingly important in SMT manufacturing:Lead-Free Solder: The use of lead-free solder and eco-friendly materials reduces environmental impact.

Energy Efficiency: Implementing energy-efficient practices and equipment minimizes resource consumption.

Manufacturers are adopting sustainable practices to reduce waste and carbon footprint, contributing to a greener future.

Future Trends in SMT PCBA Manufacturing

Looking ahead, SMT PCBA manufacturing is poised for continued innovation:Miniaturization: As devices become smaller and more powerful, the demand for compact, high-density PCBs will grow.

Advanced Materials: New materials will enhance performance and durability, expanding the possibilities for electronic products.

Emerging Markets: Growth in IoT, AI, and 5G technologies will drive demand for SMT PCBA solutions.

Conclusion

SMT PCBA manufacturing is a transformative force in the electronics industry, enabling the production of compact, high-performance devices across various sectors. By understanding the processes, advantages, challenges, and innovations in SMT PCBA manufacturing, businesses can harness its potential to drive technological advancement and meet the demands of modern consumers. For customized solutions and expert guidance, partnering with trusted suppliers like Unikeyic Electronics ensures access to cutting-edge technology and comprehensive support throughout the manufacturing journey.