Ceramic vs. Electrolytic Capacitors: Key Differences and Choosing the Right One

When designing electronic circuits, choosing the right capacitor can be crucial to the performance, reliability, and efficiency of your system. Capacitors come in various types, each with unique properties, and two of the most commonly used are ceramic capacitors and electrolytic capacitors. In this guide, we will explore the key differences between these two capacitor types and help you understand how to choose the right one for your application.

1. Introduction: Understanding Capacitors

Capacitors are essential components in modern electronics, acting as temporary storage devices for electrical energy. They store charge and release it when needed, enabling smooth and efficient operation of electrical circuits. The two most commonly used types of capacitors are ceramic capacitors and electrolytic capacitors, each serving unique functions depending on the application. Understanding their differences, characteristics, and ideal use cases can help you choose the right capacitor for your circuit.

2. Overview of Ceramic Capacitors

Ceramic Capacitors Construction

Figure 1: Ceramic Capacitors Construction

Ceramic capacitors are constructed using a ceramic material as the dielectric, with metal electrodes on either side to store and release charge. The type of ceramic material used determines the capacitor's properties, with common classifications being Class I, Class II, and Class III. These categories are based on the stability and temperature dependence of the capacitance. Class I capacitors offer the most stable capacitance, while Class III capacitors are more variable but are available in higher capacitance values.

Ceramic Capacitors Characteristics

Small Size: Ceramic capacitors are highly compact and lightweight, making them ideal for applications with space constraints, such as consumer electronics and portable devices.

Non-Polarized: Unlike electrolytic capacitors, ceramic capacitors are non-polarized, meaning they can be connected in either direction within a circuit, providing greater flexibility during installation.

Wide Range of Values: Ceramic capacitors are available in a broad range of capacitance values, from picofarads (pF) to microfarads (µF), making them versatile for a variety of applications.

Low Cost: Due to their simple construction, ceramic capacitors are inexpensive to manufacture, making them an affordable option for mass-market electronics.

3. Overview of Electrolytic Capacitors

Electrolytic Capacitors Construction

Electrolytic capacitors consist of two conductive plates (anode and cathode) separated by an electrolyte, which serves as the dielectric. The electrolyte is typically a liquid or gel substance that allows for high capacitance values, but it also means these capacitors are polarized. This means they must be installed with correct polarity—positive voltage to the anode and negative voltage to the cathode.

Electrolytic Capacitors Characteristics

Large Capacitance Values: Electrolytic capacitors are designed for applications requiring large capacitance values, making them ideal for power supply filtering, energy storage, and smoothing voltage fluctuations.

Polarized: Electrolytic capacitors must be connected in the correct orientation in a circuit. Incorrect polarity can cause capacitor failure, sometimes resulting in leakage or even explosion.

Higher Voltage Ratings: These capacitors often have higher voltage ratings than ceramic capacitors, which makes them suitable for high-voltage applications such as power supplies, amplifiers, and motor controls.

Relatively Larger Size: Due to their high capacitance, electrolytic capacitors are usually larger and bulkier than ceramic capacitors, which can be a consideration in space-constrained designs.

4. Key Differences Between Ceramic and Electrolytic Capacitors

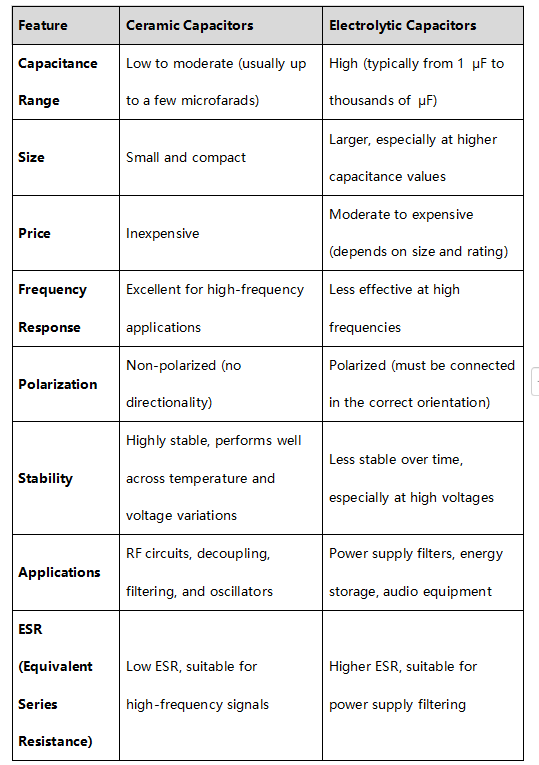

While both ceramic and electrolytic capacitors serve essential functions in electronic circuits, they differ significantly in terms of performance, design, and application suitability. Below are the key differences between ceramic vs electrolytic capacitors:

Figure 2: ceramic vs electrolytic capacitors

5. Ceramic vs Electrolytic Capacitor Performance and Reliability

Ceramic Capacitors Performance:

Temperature Stability: Ceramic capacitors exhibit varying degrees of temperature stability depending on the class of ceramic material used. Class I ceramic capacitors, typically made from stable materials like C0G/NP0, offer excellent stability over a wide temperature range and minimal capacitance change. Class II and Class III ceramics, such as X7R and Y5V, are less stable and may experience significant capacitance fluctuations with temperature changes, making them less reliable for high-precision applications.

ESR (Equivalent Series Resistance): Ceramic capacitors generally have lower ESR compared to electrolytic capacitors, which is a significant advantage in high-frequency circuits. Lower ESR reduces power loss and improves efficiency, making ceramic capacitors the preferred choice for applications involving RF (radio frequency), decoupling, and filtering in high-speed circuits.

Lifespan: Ceramic capacitors have a long operational lifespan due to their durable and robust construction. Unlike electrolytic capacitors, which use a liquid electrolyte that degrades over time, ceramic capacitors are less susceptible to wear and have an indefinite lifespan when used within specified voltage and temperature ratings.

Electrolytic Capacitors Performance:

Leakage Current: Electrolytic capacitors are more prone to leakage current, especially as they age. Leakage current can increase as the capacitor's electrolyte degrades, which can cause a gradual loss of capacitance and lead to circuit failure. In high-temperature or high-stress environments, this issue becomes more pronounced, limiting the reliability of electrolytic capacitors in long-term applications.

ESR (Equivalent Series Resistance): Electrolytic capacitors typically exhibit higher ESR compared to ceramic capacitors. This higher resistance can impact performance, especially in high-frequency applications where low ESR is crucial. In power supply circuits, higher ESR can lead to greater heat generation and power loss, reducing the overall efficiency of the system.

Lifespan: The lifespan of electrolytic capacitors is limited, typically ranging from 1,000 to 5,000 hours depending on operating conditions, such as temperature and voltage. They are more vulnerable to failure over time, especially in environments with high temperatures or frequent voltage spikes. When subjected to prolonged stress, electrolytic capacitors can degrade more quickly, leading to increased risk of failure in critical applications.

6. Applications of Ceramic Capacitors

Ceramic capacitors are versatile and widely used in a variety of applications due to their small size, reliability, and cost-effectiveness. Some of the key applications include:Decoupling/Bypass Capacitors: Ceramic capacitors are often used in power supply circuits to smooth out voltage fluctuations and reduce noise. They help stabilize the power supply by filtering high-frequency noise and ensuring clean voltage to sensitive components such as microcontrollers and ICs (integrated circuits).

Signal Filtering: These capacitors are commonly used in RF (radio frequency) and high-frequency applications to filter signals and suppress noise. Their ability to perform well in high-frequency circuits makes them ideal for communication systems, wireless devices, and signal processing.

Timing Circuits: Ceramic capacitors are often employed in oscillators, timers, and other frequency-sensitive applications, where precise timing is critical. Their stability and small size make them ideal for such use cases.Consumer Electronics: Due to their small size, low cost, and high reliability, ceramic capacitors are commonly used in smartphones, tablets, computers, and other portable consumer devices. These capacitors are ideal for compact designs where space is limited but reliability is a priority.

7. Applications of Electrolytic Capacitors

Electrolytic capacitors are used in circuits requiring higher capacitance values and greater energy storage. Some of the key applications include:Power Supply Filtering: Electrolytic capacitors are widely used in power supply circuits to smooth out rectified DC voltages and filter out ripple currents. Their ability to handle high capacitance values makes them ideal for power conditioning, ensuring stable output voltage in power supply units (PSUs).

Energy Storage: In circuits that require significant energy storage, such as audio amplifiers, motors, and high-power applications, electrolytic capacitors are the go-to choice. They can store large amounts of energy and release it when needed, making them ideal for power-hungry applications.

Bulk Capacitance: Electrolytic capacitors are essential in circuits that need to stabilize voltage or provide power during surges or spikes. They help maintain a steady supply of power to the circuit, absorbing and releasing charge as needed to protect sensitive components from voltage fluctuations.

Automotive Applications: Electrolytic capacitors are often used in car audio systems, electric vehicles, and other automotive electronics due to their ability to handle high capacitance values, high voltage ratings, and large amounts of energy storage. They help filter noise and stabilize power in automotive systems.

8. Pros and Cons of Ceramic and Electrolytic Capacitors

Ceramic Capacitors Pros:

Small size: Ceramic capacitors are compact and lightweight, ideal for space-constrained applications.

Low cost: They are affordable, making them a cost-effective choice for mass-produced electronics.

Non-polarized: They can be installed in either direction, offering greater flexibility.

Stable performance: Ceramic capacitors exhibit stable performance over a wide temperature range, particularly Class I types.

High-frequency suitability: Their low ESR makes them ideal for high-frequency applications.

Ceramic Capacitors Cons:

Lower capacitance values: Ceramic capacitors typically offer lower capacitance values, which limits their use in energy storage or power supply filtering.

Temperature sensitivity (in some classes): Class II and III ceramic capacitors can suffer from capacitance fluctuations due to temperature variations.

Potential microphonic effects: In high-voltage, high-power environments, ceramic capacitors may exhibit microphonic effects, which can interfere with signal integrity.

Electrolytic Capacitors Pros:

High capacitance values: Electrolytic capacitors are ideal for applications requiring bulk capacitance and energy storage.

Higher voltage ratings: They can handle higher voltages, making them suitable for power supply filtering and high-power applications.

Cost-effective for high-capacitance needs: While they can be more expensive than ceramic capacitors, they offer a good value for circuits requiring high capacitance.

Electrolytic Capacitors Cons:

Polarized: Electrolytic capacitors must be installed with correct polarity, or they may fail, sometimes catastrophically.

Larger size: Electrolytic capacitors are bulkier compared to ceramic capacitors, which may limit their use in space-constrained designs.

Limited lifespan: Due to their construction, electrolytic capacitors are more prone to failure over time, particularly in high-temperature environments.

Higher ESR: Electrolytic capacitors typically have higher ESR, which can reduce efficiency and performance, especially in high-frequency applications.

9. When to Use Ceramic vs. Electrolytic Capacitors

Use Ceramic Capacitors:

Ceramic capacitors are widely used in applications where small size, low cost, and reliable performance are paramount. They are particularly suitable for low-voltage, high-frequency applications due to their stable characteristics at higher frequencies.

Low-Voltage, High-Frequency Circuits: Ceramic capacitors excel in circuits where high-frequency performance is crucial. Their low ESR (Equivalent Series Resistance) makes them ideal for RF (radio frequency) applications, ensuring minimal energy loss and signal distortion. Additionally, they maintain their capacitance value and perform consistently over a wide range of temperatures, making them the go-to choice for high-frequency and high-speed applications, such as radio communication systems, Wi-Fi modules, and microwave circuits.

Consumer Electronics: Ceramic capacitors are commonly used in consumer electronics such as smartphones, tablets, laptops, and other compact devices. These devices often require capacitors that are small, inexpensive, and capable of efficiently handling power decoupling, filtering, and timing functions. Ceramic capacitors are widely used in applications like power supply filters to stabilize the voltage and reduce noise, and in oscillators and timing circuits to ensure accurate performance.

Decoupling, Filtering, and Timing Circuits: Ceramic capacitors are ideal for decoupling and bypass applications where they help smooth out voltage fluctuations and filter noise. They are essential in power supply circuits, helping to eliminate high-frequency noise from power lines and ensuring stable operation of sensitive components. Furthermore, they are commonly used in timing circuits (like oscillators and clocks), where small, stable capacitance is needed to control the timing of signals in digital circuits.

Use Electrolytic Capacitors:

Electrolytic capacitors, with their ability to store larger amounts of energy and provide higher capacitance values, are well-suited for applications where bulk capacitance and energy storage are essential. They are particularly useful in power supplies, audio amplifiers, and motor-driven systems.

High Capacitance and Energy Storage: Electrolytic capacitors are typically used in circuits requiring high capacitance values, making them essential for energy storage applications. For example, in audio amplifiers, they are used to filter the DC power supplied to the amplifier, providing the necessary bulk capacitance to stabilize the voltage and reduce power supply ripple. In motor-driven systems, electrolytic capacitors provide the energy storage needed for motors to start and maintain steady operation.

Power Supply Circuits: Electrolytic capacitors are integral in power supply systems for smoothing and filtering purposes. In AC-to-DC rectifiers, they store energy and release it to smooth out the fluctuating DC signal (the ripple) after the rectification process. Their ability to handle high voltages and store significant charge makes them ideal for stabilizing power supplies in industrial, automotive, and consumer electronics.

Filtering DC Voltage and Power Smoothing: Electrolytic capacitors are often used for filtering and smoothing applications, where DC voltage regulation is critical. In power conditioning circuits, electrolytic capacitors reduce fluctuations in the DC voltage supply, ensuring that electronic devices operate smoothly without power spikes or dips that could damage sensitive components.

Bulk Energy Storage: In circuits that require bulk energy storage, such as audio systems and industrial power systems, electrolytic capacitors store large amounts of energy and release it as needed. This is particularly important in audio amplifiers, where they provide the necessary power during peaks in audio output.

10.Why Choose unikeyic Electronics

Wide Selection: We carry a wide variety of ceramic and electrolytic capacitors suitable for various applications.

Trusted Brands: We partner with reputable manufacturers to ensure the quality and reliability of our components.

Expert Support: Our knowledgeable team can help you select the right capacitor for your specific requirements.

Competitive Pricing: Get high-quality capacitors at competitive prices, making us a cost-effective solution for all your electronic needs.

More article about ceramic vs electrolytic capacitor

Exploring the World of Capacitors with Unikeyic ElectronicsGlobal vs. Local: Finding the Right Ceramic Capacitor Supplier for Your Needs

11.Conclusion

Choosing the right capacitor for your design is a critical decision that depends heavily on the specific needs of your application. Both ceramic and electrolytic capacitors have their unique advantages and are suited for different purposes based on their characteristics, such as size, capacitance, voltage rating, and lifespan.

Choosing the Right Capacitor:

If your application requires small size, low cost, and high-frequency performance, ceramic capacitors are likely the best choice. They are ideal for decoupling, filtering, and timing circuits, especially when space is limited and cost is a concern.

On the other hand, if your design requires high capacitance for bulk energy storage, power supply filtering, or DC smoothing, electrolytic capacitors will serve you better. They are indispensable in power systems, audio amplifiers, and motor-driven circuits where larger capacitance and higher voltage ratings are necessary.

Recommendation for Designers:

When selecting between ceramic and electrolytic capacitors, carefully consider the performance requirements of your circuit. Here are a few key factors to keep in mind:Capacitance needs: Are you working with circuits that require high capacitance values or those that focus on high-frequency performance?Size and space: Is your design space-constrained? Do you need a compact solution?

Voltage and current specifications: What are the voltage and current requirements of your circuit? Will the capacitor need to handle high-voltage conditions or power surges?

Lifespan and reliability: Do you need a capacitor that can last for many years, or will the capacitor be exposed to harsh operating conditions that could affect its lifespan?

Why Choose Unikeyic Electronics for Ceramic and Electrolytic CapacitorsAt Unikeyic Electronics, we offer a comprehensive selection of ceramic capacitors and electrolytic capacitors from top brands. Whether you are designing a consumer product or an industrial system, we can provide the right capacitors for your needs.

Recommended articles related to this topic: