Why Metal Film Through-Hole Resistors Are the Gold Standard in Precision Electronics

Introduction to Metal Film Through-Hole Resistors

Definition and Role in Electronic Circuits

Metal film through-hole resistors are critical components in various electronic circuits, known for their precision, stability, and reliability. These resistors are crafted by depositing a thin layer of metal, typically a nickel-chromium alloy, onto a ceramic substrate. The metal film is then laser-trimmed to achieve precise resistance values, making these resistors indispensable in applications requiring high accuracy and minimal noise. Unlike other types of resistors, such as carbon film or wirewound resistors, metal film resistors offer superior performance, particularly in environments where consistency and low noise are paramount.

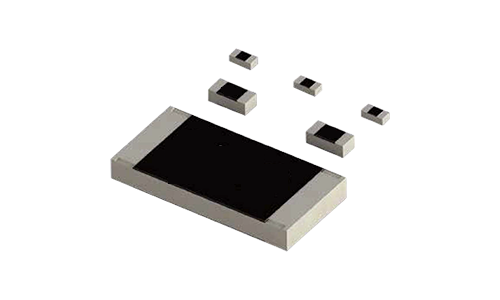

Evolution from Through-Hole to Surface-Mount Technology

The transition from through-hole to surface-mount technology (SMT) has been a significant development in electronics. However, through-hole resistors, especially metal film types, continue to be relevant due to their unique advantages. They are often used in situations where reliability, ease of use, and the ability to handle high power levels are more critical than the compact size offered by SMT components.

Key Features and Characteristics

Precision, Stability, and Low Noise

One of the most prominent features of metal film through-hole resistors is their precision. They typically offer tolerance levels ranging from ±0.1% to ±1%, making them ideal for applications where accuracy is crucial. This precision is complemented by a low temperature coefficient, which ensures that the resistance value remains stable across a wide temperature range. This stability is essential in environments where temperature fluctuations are common, ensuring that the circuit's performance is not compromised.

Another critical characteristic is the low noise level of metal film resistors. In electronic circuits, particularly in audio and signal processing, noise can significantly degrade performance. Metal film resistors are designed to minimize this noise, making them the preferred choice in high-fidelity audio equipment and precision measurement devices.

Power Rating and Performance

Metal film resistors usually have a power rating ranging from 1/8W to 2W, depending on their design and application. While they may not be the best choice for extremely high-power applications, their power handling capabilities are sufficient for most precision circuits. This balance between precision and power handling makes them versatile components in various electronic designs.

Applications of Metal Film Through-Hole Resistors

Audio Equipment

In the audio industry, metal film resistors are highly valued for their low noise and high precision. These characteristics are crucial in high-end audio equipment, such as amplifiers, mixing consoles, and other devices where sound quality is paramount. The low noise level ensures that the audio signal remains pure and undistorted, contributing to a superior listening experience.

Precision Measurement Devices

Metal film resistors are also integral to precision measurement devices like voltmeters, oscilloscopes, and other instruments that require highly accurate readings. The stability and low temperature coefficient of these resistors mean that measurements remain consistent even under varying environmental conditions, which is essential for accurate data collection and analysis.

Medical Instruments

In the medical field, the accuracy and reliability of metal film resistors are critical. Devices like ECG machines, blood pressure monitors, and other diagnostic tools rely on these resistors to function correctly. In these applications, the precision of metal film resistors is not just a matter of performance but also of patient safety, making them the preferred choice in medical electronics.

Comparing Metal Film Resistors with Other Types

Metal Film vs. Carbon Film Resistors

When comparing metal film resistors to carbon film resistors, several key differences emerge. Carbon film resistors, while less expensive, offer lower precision and higher noise levels. This makes them less suitable for high-accuracy applications where stability and low noise are essential.

Metal Film vs. Wirewound Resistors

Wirewound resistors can handle higher power levels than metal film resistors, but they are bulkier and may introduce inductance into the circuit, which can be problematic in high-frequency applications. Metal film resistors, on the other hand, provide a balance of precision, low noise, and adequate power handling, making them suitable for a broader range of applications.

Design Considerations for Using Metal Film Through-Hole Resistors

Selecting the Right Resistor

When designing a circuit with metal film through-hole resistors, it is crucial to consider factors such as the resistor value, tolerance, and power rating. These parameters will determine the accuracy and stability of the circuit. Ensuring that the selected resistor meets the circuit's requirements is essential for optimal performance.

Placement and Thermal Management

Resistor placement on the PCB is another important consideration. Proper placement can minimize the effects of parasitic inductance and capacitance, which can affect circuit performance, particularly in high-frequency applications. Additionally, adequate thermal management is crucial to prevent thermal drift and ensure that the resistors maintain their specified characteristics over time.

Manufacturing Process and Material Composition

Metal Deposition and Trimming

The manufacturing process of metal film resistors involves depositing a thin metal layer onto a ceramic substrate. This metal layer is typically made of a nickel-chromium alloy, chosen for its stability and resistance to oxidation. The metal film is then laser-trimmed to achieve the exact resistance value, ensuring high precision and reliability.

Impact on Performance

The choice of materials and the precision of the trimming process significantly impact the resistor's performance. The use of high-quality materials ensures that the resistor can withstand various environmental conditions, while the precision trimming process guarantees that the resistor will perform consistently across its specified range.

Challenges in Using Metal Film Through-Hole Resistors

Thermal Drift and Environmental Factors

While metal film resistors offer many advantages, they are not without challenges. One potential issue is thermal drift, where the resistance value changes due to temperature variations. While these resistors are designed to minimize this effect, it can still be a concern in extremely sensitive applications.

Environmental factors, such as humidity and exposure to harsh chemicals, can also affect the performance of metal film resistors. Proper encapsulation and sealing can mitigate these effects, but designers must be aware of these potential issues when selecting and placing resistors in a circuit.

Future Trends and Innovations in Resistor Technology

Advancements in Materials and Manufacturing

The field of resistor technology is continually evolving, with advancements in materials and manufacturing techniques driving improvements in performance and reliability. For metal film resistors, future innovations may focus on enhancing temperature stability, reducing size, and improving environmental resilience.

Integration with Emerging Technologies

As electronic devices become more compact and power-efficient, the demand for resistors that can operate reliably in increasingly challenging conditions will grow. Metal film resistors are well-positioned to meet these demands, particularly in emerging technologies such as IoT devices, wearable technology, and advanced medical equipment.

Environmental and Sustainability Aspects

Sustainability in Resistor Manufacturing

As with all electronic components, the production and disposal of resistors have environmental implications. Metal film resistors, in particular, require the use of metals that must be mined and processed, which can have significant environmental impacts. However, advances in manufacturing techniques are helping to reduce these impacts by improving material efficiency and reducing waste.

Eco-Friendly Designs

In the design of electronic products, selecting components with a lower environmental impact is becoming increasingly important. Metal film resistors, with their long lifespan and high reliability, can contribute to the creation of more sustainable electronics by reducing the need for replacements and minimizing waste.

Selecting Reliable Suppliers for Metal Film Through-Hole Resistors

Importance of a Reliable Supplier

Choosing the right supplier is crucial to ensuring the quality and reliability of metal film through-hole resistors. A reputable supplier like unikeyic Electronics offers several advantages, including a wide range of high-quality components, rigorous quality assurance processes, and excellent customer support.

Evaluating Suppliers

When selecting a supplier, it's essential to consider factors such as product availability, pricing, and technical support. Unikeyic Electronics stands out by offering a comprehensive selection of resistors, including metal film through-hole options, and providing the expertise needed to help customers select the right components for their specific applications.

Conclusion

Metal film through-hole resistors are a vital component in precision electronics, offering unparalleled accuracy, stability, and low noise performance. Whether used in audio equipment, precision measurement devices, or medical instruments, these resistors provide the reliability and performance needed for the most demanding applications.

As technology continues to advance, metal film resistors will remain a crucial element in electronic circuit design. By understanding their characteristics, applications, and the challenges they present, designers can make informed decisions that enhance the performance and longevity of their products. And by choosing reliable suppliers like Unikeyic Electronics, they can ensure that they are using the best components available to meet their design goals.

Related through-hole resistors articles recommended

What size is a common through-hole resistor?Maximize Your DIY Electronics with These Best Through-Hole Resistor KitsWhere to Buy the Best Through-Hole Resistor Kits OnlineSMD Resistors vs. Through-Hole Resistors: What’s the Difference?Through Hole Resistor Packages: What You Need to Know Before Buying