1. What is an oscilloscope?

An oscilloscope is a very versatile electronic measuring instrument. It can transform invisible electrical signals into visible images, making it easy for people to study the process of various electrical phenomena. Oscilloscopes utilize a narrow, high-speed electron beam composed of electrons, which hits the screen surface coated with fluorescent material, producing a small point of light. Under the action of the measured signal, the electron beam resembles the tip of a pen, capable of depicting the change curve of the instantaneous value of the measured signal on the screen surface. It has critical applications in various fields, including electronics, electrical engineering, communications, and computers, such as observing signal wave forms, measuring frequency, amplitude, phase, and other signal parameters, and providing a powerful tool for debugging, troubleshooting, and scientific research of circuits.

Composition of oscilloscope

Oscilloscope: The Oscilloscope is the core part of the oscilloscope, composed of an electron gun, a deflection system, and a fluorescent screen. The electron gun launches an electron beam, which is controlled by the deflection system and hits the fluorescent screen to form a light spot. The phosphor screen is coated with a fluorescent substance that glows when the electron beam hits it, creating a visible waveform.

Vertical (Y-axis) Amplifier Circuit: Amplifies the input signal to display the appropriate amplitude on the phosphor screen.

Horizontal (X-axis) Amplifier Circuit: Generates a sabretooth wave scanning signal, which is used to control the horizontal scanning of the electron beam on the phosphor screen to display the time axis of the signal.

Scanning and Synchronization Circuit: generates the sabretooth wave voltage to form the time baseline of the electron beam on the fluorescent screen and ensures that the scanning of the electron beam is synchronized with the frequency and phase of the input signals to display the waveform of the signals correctly.

Power supply circuit: provides the required power supply for each part of the oscilloscope, including high-voltage power supply, filament power supply, etc.

Probe: usually divided by the measurement object, there are two kinds of voltage probes and current probes. Voltage probes include passive probes and active probes. Passive probes in the 1X, 10X, 100X, and 1000X ranges can measure up to 40KV at high voltage. Active probes, which include both ordinary and differential types, are primarily used. For the active probes, the maximum safety voltage limit is often tens of volts. To avoid personal safety hazards and the potential danger of damaging probes, it is essential to know the voltage range being measured and the voltage limits of the probes to be used. Active differential probes help you observe differential signals. Differential signals are signals referenced to each other, not to ground. Differential probes have higher performance when used with matched pairs of single-ended probes, providing high CMRR, wide bandwidth, and minimal time differences between input signals. High bandwidth differential probes provide excellent signal fidelity to meet the needs of engineers and technicians designing and debugging at fast clock rates and clock edge rates. Current probes include AC probes and AC/DC probes. AC probes are usually passive probes, and AC/DC probes are usually active probes.

2. Types of oscilloscopes

Oscilloscopes are generally divided into analog oscilloscopes and digital oscilloscopes. While both can be used for testing, analog oscilloscopes are typically preferred for signals that require real-time display and change rapidly, as well as for complex signals. Digital oscilloscopes are used to display the periodicity of relatively strong signals, including both digital and analog signals. Their built-in CPU or special digital signal processor enables the analysis of signals and the saving of wave forms, providing significant convenience during analysis and processing.

2.1 Analog Oscilloscope

An analog oscilloscope uses an electron gun to scan the screen of the oscilloscope, with deflection voltage, so that the electron beam scans uniformly from top to bottom, and the waveform will be displayed on the screen. Its advantage lies in the real-time display of images.

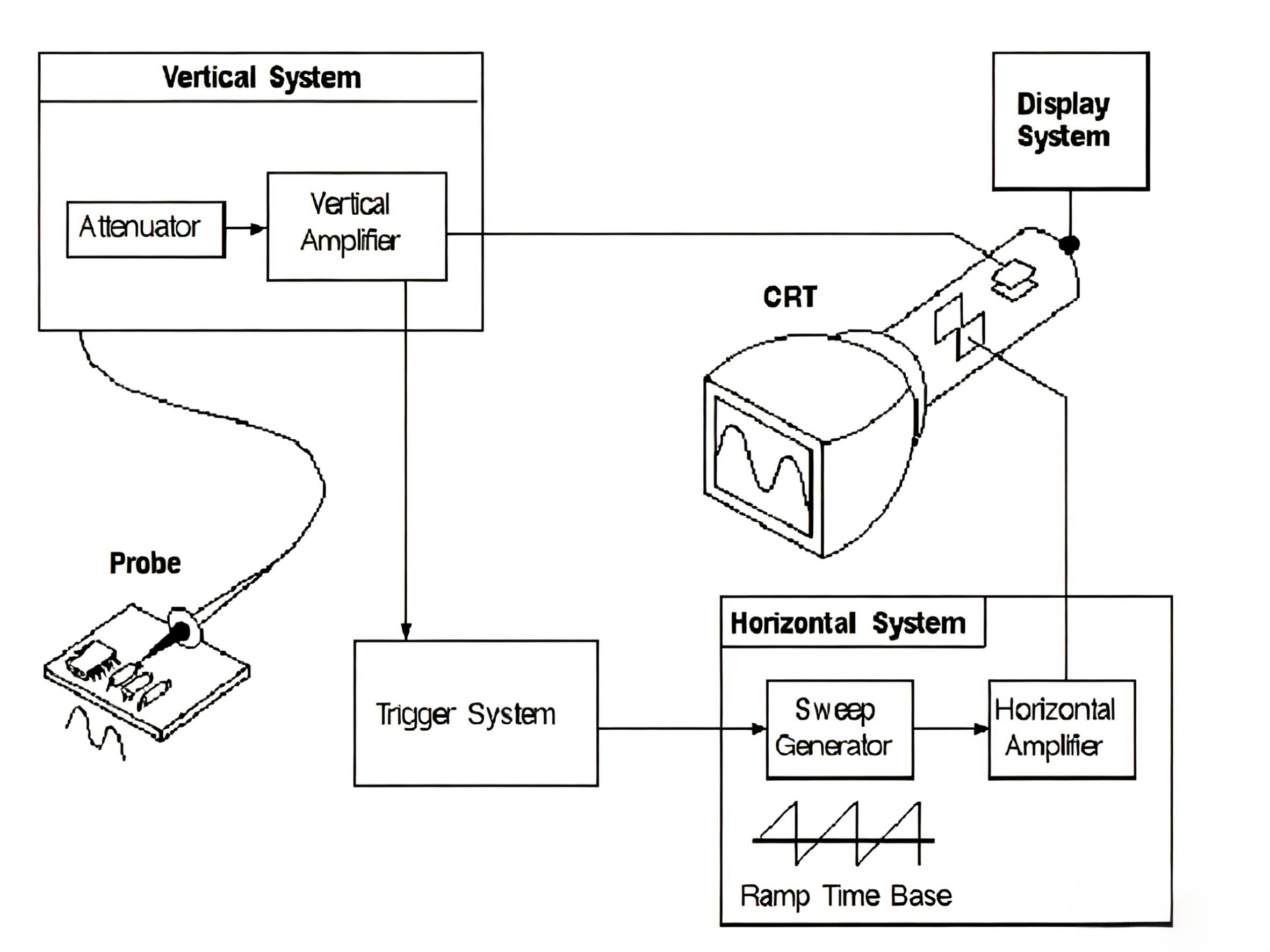

The block diagram of an analog oscilloscope is shown below:

The above diagram shows that the signal under test is processed by the vertical system (such as attenuation or amplification, i.e., we screw the vertical button -volts/div), and then sent to the vertical deflection control. And the trigger system will control the generation of the horizontal scanning voltage (sabretooth wave) to be sent to the horizontal deflection control, depending on the trigger setting.

The signal arrives at the trigger system and starts or triggers a "horizontal scan", which is a sabretooth wave that scans the dot horizontally. Triggering the horizontal system produces a horizontal time base that causes the dot to scan from the left to the right side of the screen in a precise amount of time. The fast scanning process will make the motion of the dot look like a smooth curve. The signal voltage applied to the electrodes of the vertical deflection voltage also has the effect of creating a moving dot. A positive voltage will move the dot upward, a negative voltage will move it downward, and the horizontal and vertical deflection voltages together will be able to display the waveform of the signal on the screen. At a relatively high speed, the bright spot can scan across the screen up to 50,000 times/second. In contrast, the best general-purpose oscilloscope can only capture 40,000 waveforms per second. This makes analog oscilloscopes more real-time than digital oscilloscopes, which is the real deal.

Horizontal scanning and vertical deflection enable the waveform image of a signal to be displayed on the screen, however a trigger system is also essential, not only does it allow you to capture the waveform you need, but it also enables the image to be displayed on the screen stably, it enables repetitive wave forms to be scanned at the same point to start the scanning process, displaying a clean and stable image on the screen.

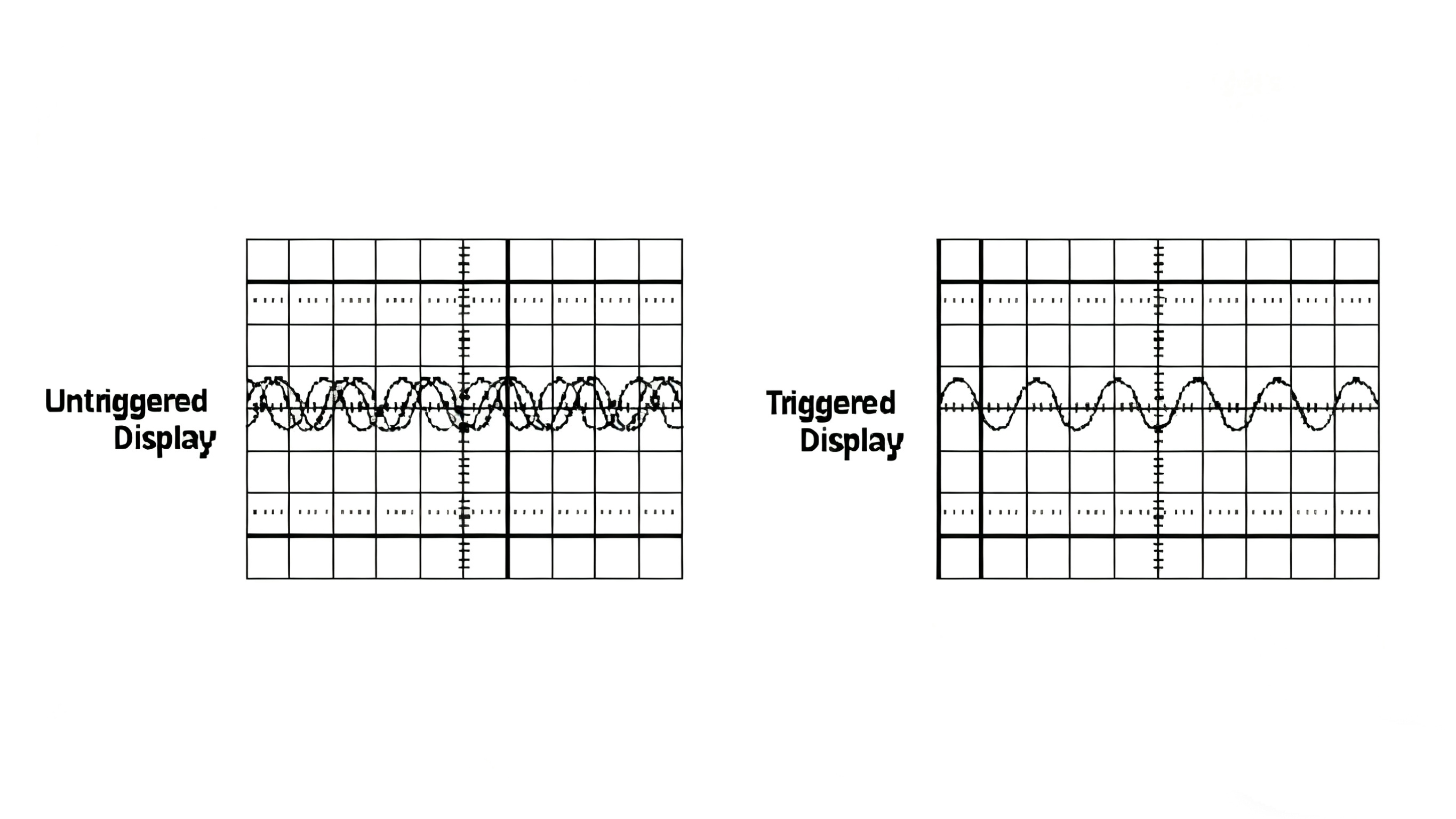

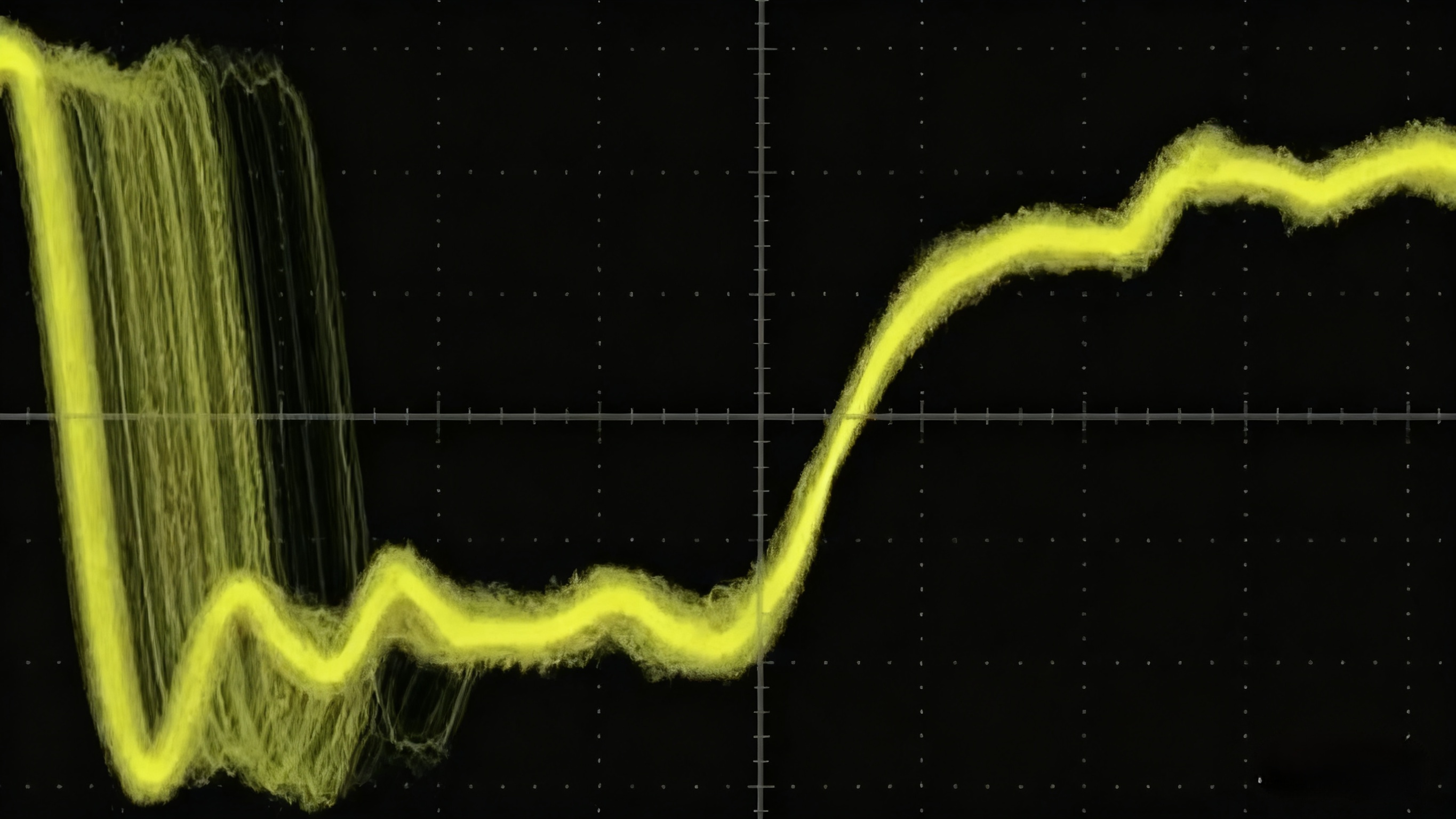

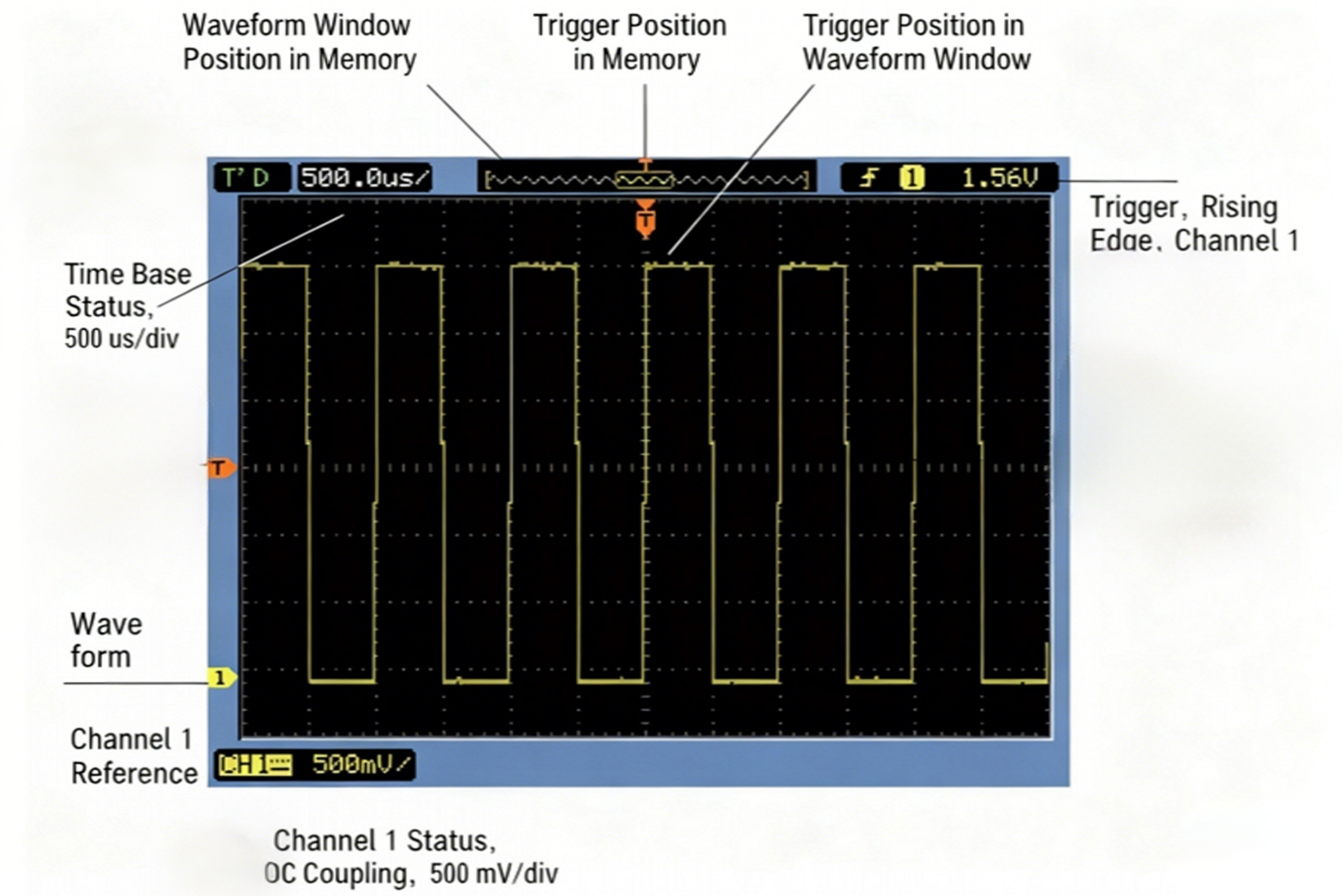

The photo below shows the intrigued and triggered wave forms: the intrigued waveform is messy, flickering, and unstable, while the triggered waveform is very stable and clean.

Generally speaking, with an analog oscilloscope, we need to adjust three fundamental aspects, the three parts mentioned above:

The attenuation or amplification of the signal: using the volts/div knob, you can adjust the signal to be inside the scope of the screen, with the correct vertical size.

Time base: Using the sec/div knob, the time interval represented by each frame can be adjusted to make the signal zoom in or out horizontally.

Trigger system: You can adjust the trigger level to stabilize the waveform display or locate the desired waveform.

Of course, adjusting the size of the bright spot and the bright bottom can make the waveform display achieve the best display effect.

2.2 Digital Oscilloscope

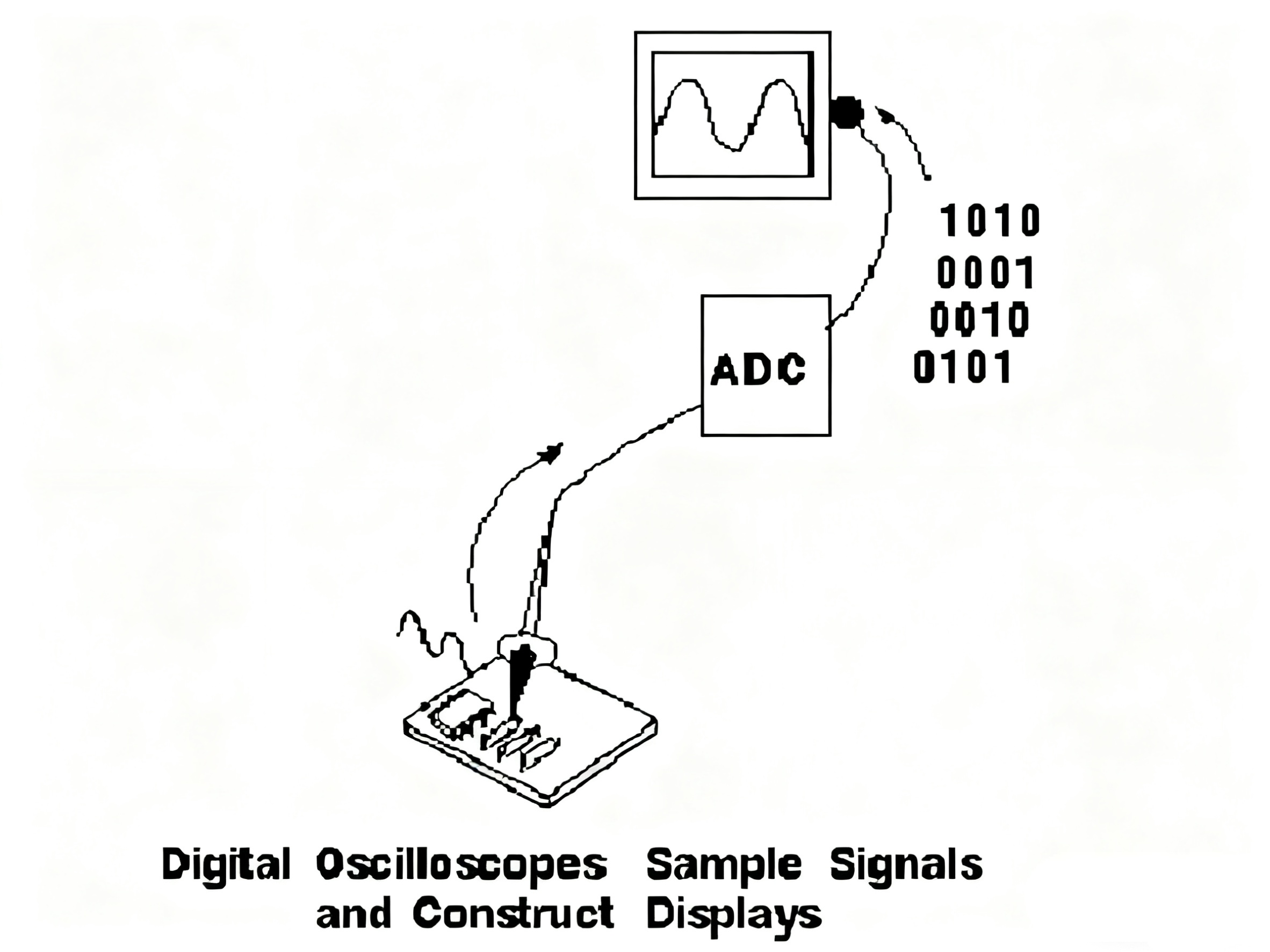

A digital oscilloscope samples the wave forms and uses an ADC to convert the analog image to digital wave forms, and finally reproduces the wave forms on the screen.

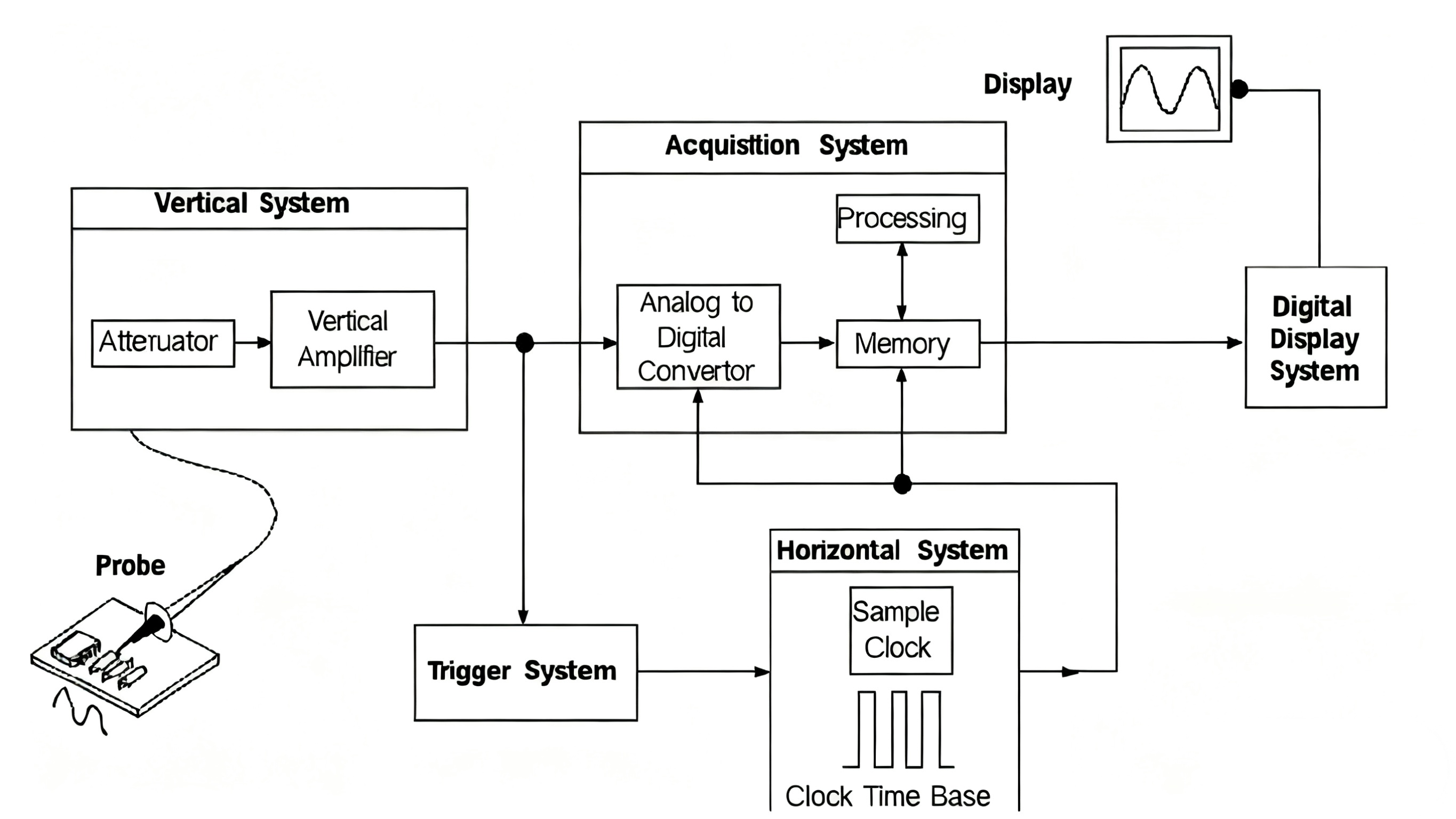

The schematic diagram of a digital oscilloscope is shown below:

When we connect the probe to the top of the line, the vertical system controls the adjustment of the attenuation and amplification of the signal, which is the same as that of the analog oscilloscope. Next, the analog-to-digital conversion (ADC) is performed on the signal in the sampling system, and the continuous analog signal becomes discrete dots. The time base of the level system determines the level of the sampling rate.

For example, our TDS5054 has a maximum sampling rate of 5GSa/s, indicating that it is capable of sampling 5G points per second at its fastest. The sampled and antiquated points are stored in memory and pieced together into a waveform graph.

In digital oscilloscopes, the length of the stored waveform points is often referred to as the memory length. Due to their high-speed processing requirements, these memories are not general-purpose Dramas but specialized high-speed memories, which are more expensive; therefore, cheaper oscilloscopes use standard configurations. The trigger system determines the start and end points of the save point. The wave forms inside the memory are finally transferred to the display system for display.

Data processing is necessary to enhance the oscilloscope's synthesizing power. In addition, ore-triggering enables us to see the waveform before triggering.

As with analog oscilloscopes, testing with a digital oscilloscope requires adjusting the vertical amplitude, horizontal time interval, and trigger settings.

3. How does an oscilloscope work?

An oscilloscope is an electronic measuring instrument that utilizes the characteristics of an electronic oscilloscope to convert alternating electrical signals, which are not directly observable by the human eye, into an image that is displayed on a fluorescent screen for measurement. It is an essential instrument for observing the experimental phenomena of digital circuits, analyzing the problems in the experiments, and measuring the experimental results. The oscilloscope consists of an oscilloscope and power supply system, a synchronization system, an X-axis deflection system, a Y-axis deflection system, a delay scanning system, and a standard signal source.

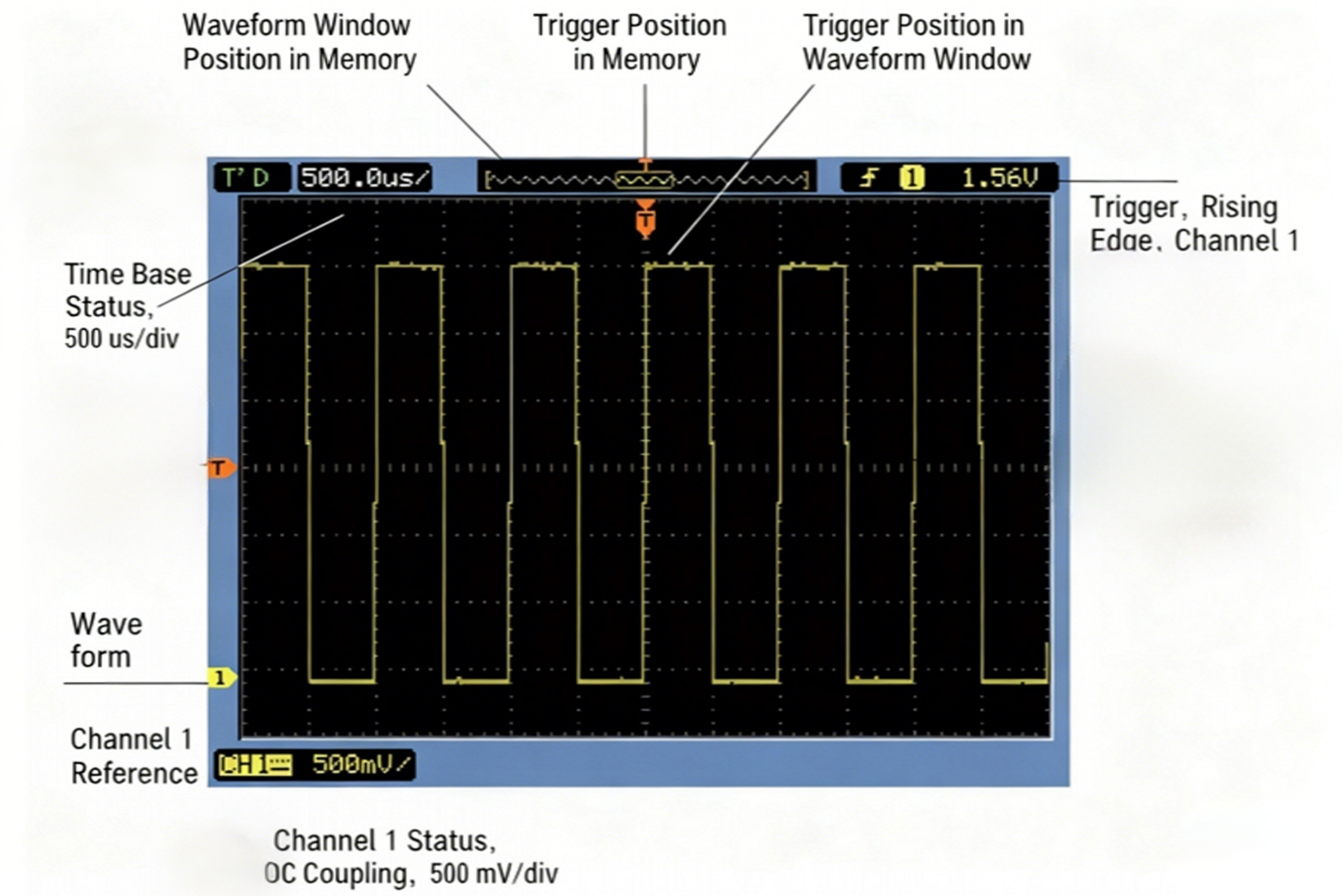

3.1 Fluorescent screen

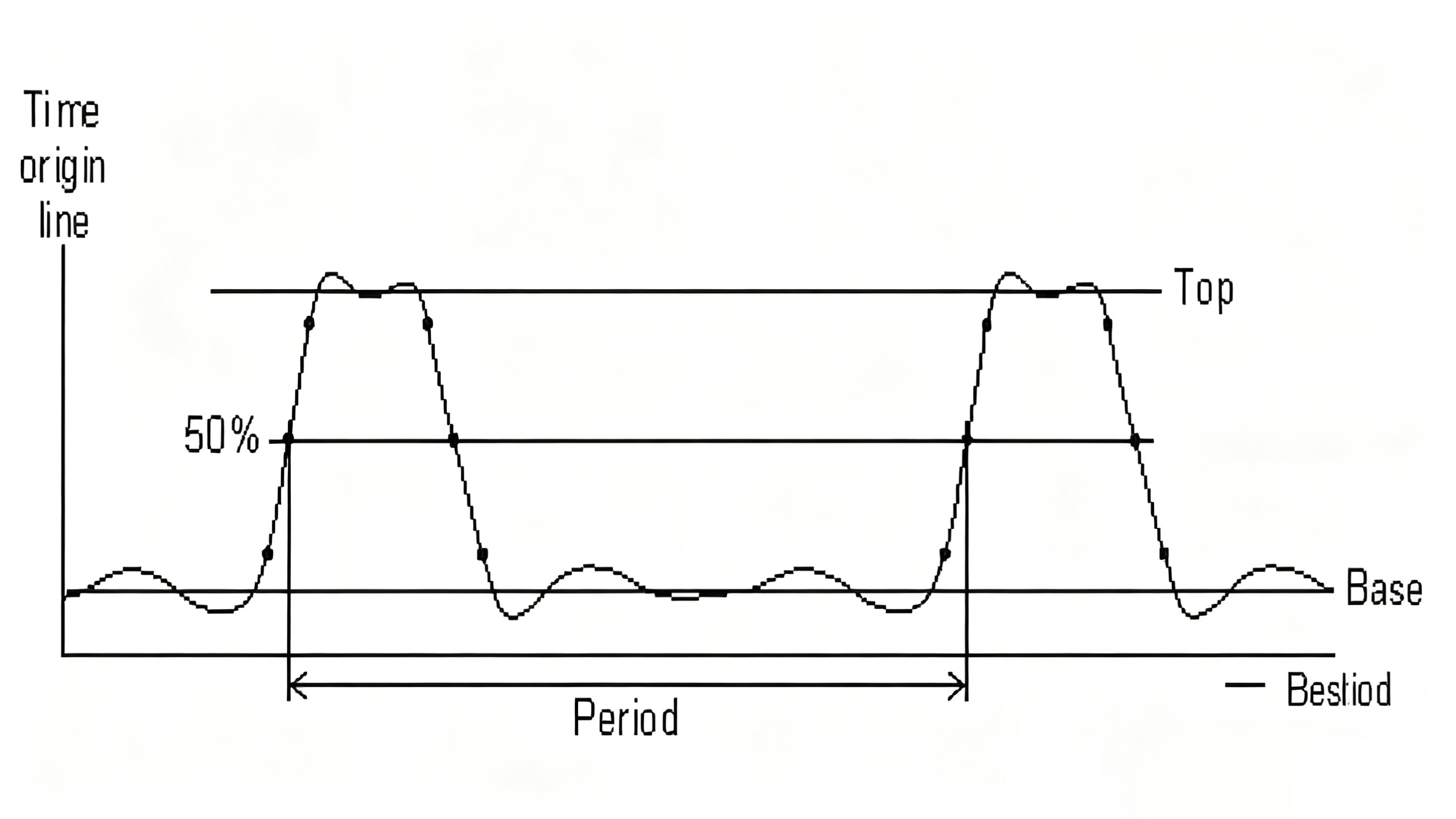

The fluorescent screen is the display part of the oscilloscope. There are several scale lines on the screen in the horizontal and vertical directions, indicating the relationship between voltage and time of the signal waveform. The horizontal direction indicates the time, and the vertical direction indicates the voltage. The horizontal direction is divided into 10 frames, and the vertical direction is divided into eight frames, each of which is further divided into five parts. Vertical direction is marked with 0%, 10%, 90%, 100%, etc. The horizontal direction is marked with 10% and 90% for measuring DC level, AC signal amplitude, delay time, and other parameters. According to the measured signal on the screen, the number of frames can be derived from the voltage value and time value by multiplying by the appropriate constant of proportionality (V / DIV, TIME / DIV).

3.2 Oscilloscope and power system

(1) Power supply (Power)

The oscilloscope's main power switch. When this switch is pressed, the power indicator lights up, indicating that the power supply is on.

(2) Glow (Intensity)

Rotate this knob to change the brightness of the light spot and scan line. Observe that low-frequency signals can be smaller, high-frequency signals larger.

Generally, it should not be too bright to protect the fluorescent screen.

(3) Focus

The focus knob is used to adjust the size of the electron beam cross-section, and the scanning line will be focused into the clearest state.

(4) Scale brightness (Illuminance)

This knob adjusts the brightness of the illuminate behind the fluorescent screen—normal indoor light results in darker illumination. In an environment with insufficient indoor light, the illumination can be adjusted appropriately.

3.3 Vertical deflection factor and horizontal deflection factor

(1) Vertical Deflection Factor Selection (VOLTS/DIV) and Fine Tuning

Under the action of the unit input signal, the distance that the point of light is deflected on the screen is called the offset sensitivity, and this definition applies to both the X-axis and the Y-axis. The reciprocal of the sensitivity is called the deflection factor. Vertical sensitivity is measured in cm/V, cm/V, or DIV/V, DIV/V, and vertical deflection factor is measured in V/cm, V/cm, or V/DIV, V/DIV. In fact, the deflection factor is sometimes used as the sensitivity due to customary usage and the convenience of measuring voltage readings.

Each channel of the oscilloscope has a vertical deflection factor selector switch. The band switches are generally divided into 10 steps from 5mV/DIV to 5V/DIV in 1, 2, and 5 steps. The value indicated by the band switch represents the voltage value of the vertical direction of a frame on the fluorescent screen. For example, when the band switch is placed in 1V / DIV gear, if the signal light point on the screen moves by one frame, it represents a 1V change in the input signal voltage.

There is often a small knob on each band switch to fine-tune the vertical deflection factor of each gear. Turn it clockwise to the end, in the "calibration" position, when the vertical deflection factor value is the same as the value indicated by the band switch. Turn this knob counterclockwise to fine-tune the vertical deflection factor. It should be noted that the fine adjustment of the vertical deflection factor may cause inconsistency with the value indicated by the band switch. Many oscilloscopes have a vertical expansion function, which expands the vertical sensitivity (and reduces the deflection factor) by a factor of several when the fine adjustment knob is pulled out. For example, if the deflection factor indicated by the band switch is 1V/DIV, the vertical deflection factor is 0.2V/DIV when the ×5 expansion state is used.

When doing digital circuit experiments, the ratio of the vertical travel distance of the measured signal on the screen to the vertical travel distance of the +5V signal is often used to determine the voltage value of the measured signal.

(2) Time Base Selection (TIME/DIV) and Trimming

Time base selection and trim are used in a similar way to vertical deflection factor selection and trim. The time base selection is also realized by a band switch, which divides the time base into several steps, such as 1, 2, and 5. The indication value of the band switch represents the time value for the point of light to move horizontally by one frame. For example, in the 1μS/DIV mode, the point of light moving one frame on the screen represents a time value of 1μS.

The "Trim" knob is used for time base calibration and trimming. When the knob is rotated clockwise to the calibration position, the time base value displayed on the screen corresponds to the nominal value indicated by the band switch. Turning the knob counterclockwise fine-tunes the time base. When the knob is removed, it is in the scanning expansion state. For example, at 2μS/DIV, the time value represented by one horizontal frame on the fluorescent screen in the scanning expansion state is equal to

2μS×(1/10)=0.2μS

There are 10MHz, 1MHz, 500kHz, and 100kHz clock signals on the TDS test bench, which are generated by a quartz crystal oscillator and a frequency divider with high accuracy, and can be used to calibrate the time base of the oscilloscope.

The oscilloscope's standard signal source, CAL, is specifically designed to calibrate the oscilloscope's time base and vertical deflection factor. For example, the COS5041 oscilloscope standard signal source provides a square wave signal with VP=2V and f=1kHz.

The Position knob on the front panel of the oscilloscope adjusts the position of the signal waveform on the fluorescent screen. Rotate the horizontal displacement knob (labeled with horizontal two-way arrow) to move the signal waveform left and right, and rotate the vertical displacement knob (labeled with vertical two-way arrow) to move the signal waveform up and down.

3.4 Input channel and input coupling selection

(1) Input channel selection

There are at least three ways to select the input channel: channel 1 (CH1), channel 2 (CH2), and dual channel (DUAL). When channel one is selected, the oscilloscope only displays the signal of channel 1. When Channel 2 is selected, the oscilloscope only displays the signal of Channel 2. When selecting DUAL, the oscilloscope displays the signals of channel one and channel two simultaneously. To test the signals, first connect the ground of the oscilloscope to the ground of the circuit under test. According to the selection of the input channel, plug the oscilloscope probe into the corresponding channel socket. The ground on the oscilloscope probe is connected to the ground of the circuit under test, and the oscilloscope probe touches the point under test. The oscilloscope probe has a two-position switch. This switch is dialed to the "× 1" position, the measured signal is sent to the oscilloscope without attenuation, and the voltage value read out from the fluorescent screen is the actual voltage value of the signal. This switch is dialed to the "× 10" position, the measured signal attenuation for 1 / 10, and then sent to the oscilloscope. From the fluorescent screen, read out the voltage value multiplied by 10, which is the actual voltage value of the signal.

(2) Input coupling method

Input coupling mode has three options: alternating current (AC), ground (GND), and direct current (DC). When "Ground" is selected, the scan line shows the position of "Oscilloscope Ground" on the fluorescent screen. DC coupling is used to determine the absolute DC value of signals and to observe very low-frequency signals. AC coupling is used to observe AC and DC signals. In digital circuit experiments, the general choice of "DC" mode is made to observe the absolute voltage value of the signal.

3.5 Triggering

After the measured signal is input from the Y-axis, a part of it is sent to the Y-axis deflection plate of the oscilloscope to drive the light point to move along the vertical direction on the fluorescent screen according to the ratio; another part of it is shunted to the x-axis deflection system to generate a trigger pulse, which triggers the scanning generator and produces a repetitive sabretooth voltage added to the X-axis deflection plate of the oscilloscope to make the light point to move along the horizontal direction.

The two of them are combined, and the light point is depicted in the graphic on the fluorescent screen, that is, the graphic of the measured signal. The graph shown by the light spot on the fluorescent screen is the measured signal graph. It can be seen that the correct trigger mode directly affects the effective operation of the oscilloscope. To achieve a stable and transparent signal waveform on the fluorescent screen, mastering the basic trigger function and its operation is crucial.

(1) Trigger source selection

To make the screen display a stable waveform, it is necessary to measure the signal itself, or to measure the signal with a specific time relationship with the trigger signal added to the trigger circuit. Trigger source selection determines where the trigger signal is supplied. There are usually three trigger sources: internal trigger (INT), power trigger (LINE), and external trigger EXT).

The internal trigger uses the signal under test as the trigger signal and is a frequently used trigger method. Since the trigger signal itself is part of the signal under test, a very stable waveform can be displayed on the screen. Channel 1 or channel 2 in dual-trace oscilloscopes can be selected as the trigger signal.

Power triggering uses the AC power supply frequency signal as the trigger signal. This method is effective in measuring signals related to the AC power supply frequency. It is especially effective in measuring low-level AC noise in audio circuits and gate tubes.

External triggering uses an external signal as the trigger signal, which is input from the external trigger input. There should be a periodic relationship between the external trigger signal and the measured signal. Since the signal under test is not used as the trigger signal, the scanning start time is independent of the signal under test.

The correct selection of the trigger signal has a great deal to do with the stability and clarity of the waveform display. For example, in the measurement of digital circuits, for a simple periodic signal, the choice of internal triggering may be better. In contrast, for a signal with a complex cycle and a periodic relationship, the choice of external triggering may be better.

(2) Trigger coupling mode selection

Trigger signals to the trigger circuit of the coupling method can be achieved in various ways. The purpose is to ensure signal stability and reliability. Here are a few commonly used.

AC coupling is also known as capacities coupling. It allows only the AC component of the trigger signal to be triggered, and the DC component of the trigger signal is isolated. This type of coupling is usually used when the DC component is not considered to form a stable trigger. However, if the frequency of the trigger signal is less than 10 Hz, it can cause triggering difficulties.

Direct current coupling (DC) does not isolate the DC component of the trigger signal. When the frequency of the trigger signal is low or the duty cycle of the trigger signal is large, it is better to use DC coupling.

When the trigger signal is triggered by low frequency rejection (LFR), the trigger signal is added to the trigger circuit through a high-pass filter, and the low-frequency component of the trigger signal is suppressed; when the trigger signal is triggered by high frequency rejection (HFR), the trigger signal is added to the trigger circuit through a low-pass filter, and the high-frequency component of the trigger signal is suppressed. In addition, there is a TV synchronization (TV) trigger for TV maintenance. These trigger coupling methods have their own scope of application and require experience in use.

(3) trigger level and trigger polarity (Slope)

Trigger level adjustment, also known as synchronization adjustment, synchronizes the scanning and the measured signal. The level adjustment knob adjusts the trigger level of the trigger signal. Once the trigger signal exceeds the trigger level set by the knob, the scan is triggered. Turning the knob clockwise increases the trigger level; counterclockwise decreases the trigger level. When the level knob is adjusted to the level lock position, the trigger level is automatically kept within the amplitude of the trigger signal, and a stable trigger can be generated without level adjustment. When the signal waveform is complex, the level knob can not stabilize the trigger. Use the release suppression (Hold Off) knob to adjust the release suppression time of the waveform (scanning pause time), which can make the scanning and the waveform stabilization in sync.

The polarity switch is used to select the polarity of the trigger signal. When the switch is set to the "+" position, the trigger will be generated when the trigger signal exceeds the trigger level in the direction of signal increase. In the "-" position, the trigger is generated when the trigger signal exceeds the trigger level in the direction of signal decrease. Trigger polarity and trigger level together determine the trigger point of the trigger signal.

3.6 Scanning mode (Sweep Mode)

Scanning has three kinds of scanning modes: automatic (Auto), standard (Norm), and single (Single).

Auto: When there is no trigger signal input, or the trigger signal frequency is lower than 50Hz, the scanning is in self-excited mode.

Normal: When there is no trigger signal input, the scanning is in the ready state, and there is no scanning line. When the trigger signal arrives, the scan is triggered.

Single: The single button is similar to the reset switch. Under the single scanning mode, the scanning circuit is reset when the single button is pressed, and the Ready light is on at this time. A single scan is generated when the trigger signal arrives. When the single scan is finished, the Ready lamp goes out. A single scan is used to observe non-periodic signals or single transient signals, which often require taking pictures of the waveform.

4. What is an oscilloscope used for?

4.1 Three major applications of oscilloscopes

(1) Oscilloscope Application 1

Debugging of general-purpose signals, waveform observation and measurement of basic waveform parameters, circuit diagnosis, and capture of anomalies. Using an oscilloscope to test a circuit is actually similar to using a altimeter to test a circuit. Knowing the general voltage of the circuit, you can quickly find the problem based on the voltage. Know what kind of wave forms are being measured, and compare them.

(2) Oscilloscope Application 2

Advanced analysis of signals enables the decoding of serial signals from the content carried vertically. An eye diagram is a series of digital signals displayed on the oscilloscope's cumulative graphic display. It contains a wealth of information that can be observed with the eye on the crosstalk between the code and the impact of noise, reflecting the overall characteristics of the digital signal, to estimate the extent of the system's strengths and weaknesses.

(3) Oscilloscope Application 3

In the modulation domain analysis of ultra-waveband signals, you can use the spectrometer as a down converter, with a UWB bandwidth of more than 500MHz or even up to a few GHz, with an oscilloscope display. UWB communication systems do not require a "sinusoidal carrier" but directly emit electromagnetic pulses. By adjusting the amplitude of these pulses (PAM, Pulse Amplitude Modulation) and the position of the pulses (PPM, Pulse Position Modulation), as well as other methods, information can be transmitted.

4.2 Oscilloscope Applications

The application of the oscilloscope has been extended from traditional electronic circuit debugging to cutting-edge science and technology, with domestic equipment being adapted to achieve breakthroughs in the field.

Communication industry: multi-channel phase synchronization for 5G base station. Aweigh 5G base station adopts Massive MIMO technology, which requires phase calibration of 64-channel antenna signals. Pu yuan Variation DS70000 series oscilloscopes (12 GHz bandwidth) reduce the cost of single base station testing by 40% by replacing Eyesight DSOX9254A with multi-channel synchronized sampling (bitter <1 PS).

New Energy Vehicles: Dynamic Characterization of SAC Power Devices. BYD SAC inverters need to measure Switching Loss and AV/at immunity. Inyanga Technology's SDS6000 Pro oscilloscope (1 GHz bandwidth) with a high-voltage differential probe (2000V isolation) achieves a switching loss analysis error of <3%, which is close to the performance of Eyesight Infinitival series.

Semiconductor: Timing Verification of DDR5 Interface. Semiconductor Manufacturing International (SMIC) 28nm process chips require verification of the timing bitter of the DDR5 interface. RIGOL DS8000 series oscilloscopes (5 GHz bandwidth) capture sub-nanosecond timing deviation (<0.1 UI) through equivalent sampling technology, helping customers to pass JEDEC certification.

Scientific research: Microwave control signal monitoring for quantum computers. MicroScan STO3000 oscilloscopes (1 GHz bandwidth) are used to monitor the microwave control signal of superconducting quantum bits, with a phase noise of <-150 dBc/Hz, which meets the demand for high-precision control of quantum states.

5. Display & measurement mechanisms

Oscilloscopes are the most common instruments used by electronic engineers, and many people compare oscilloscopes to the "eyes" of engineers, which is a good indication of how vital oscilloscopes are to engineers. How are signals displayed on the oscilloscope screen?

On an oscilloscope, the signal is transmitted through a series of resistors and capacitors inside the Probe. The signal then enters the oscilloscope and passes through the analog input signal modulation module. Depending on the size of the signal, it is scaled up or down accordingly to get within the dynamic range of the analog-to-digital converter (ADC). The analog signal is converted to digital data (1's and 0's) in the ADC module. At the same time, the trigger module compares the signal to a specified trigger condition. The trigger condition tells the time base module when to capture the digital data and save it to the cyclic acquisition memory. The digital signal processing module (DSP) analyzes the digital data and then reconstructs it into a waveform for display on the screen.

For all oscilloscopes, after the signal is displayed on the oscilloscope, the next step is to make the appropriate measurements. Oscilloscopes are now extremely rich in built-in measurement capabilities, allowing engineers to analyze the amplitude and time parameters of a waveform quickly. Examples of these basic measurements include:

5.1 Measuring Analog Signals

Several important metrics of analog signals can be measured using an oscilloscope. The following are some common signal characteristics that an oscilloscope can measure:

Amplitude: Indicates the size of the peak of a signal. An oscilloscope can visualize the amplitude of a signal.

Frequency: Indicates the periodicity of a signal. By measuring the period or pulse width of a signal, the frequency of the signal can be determined.

Period: Indicates the time of a complete cycle of a signal.

Phase: Indicates the offset of the signal waveform relative to a reference signal. Phase is usually expressed as an angle or time delay.

Peak: indicates the difference between the peak and trough of the signal.

Root Mean Square (RMS): Indicates the RMS value of a signal, which is equivalent to the DC value of the signal. Harmonic Analysis: An oscilloscope can help analyze the harmonic components of a signal by showing the fundamental and harmonics of each order in the signal.

Phase Difference: Used to measure the relative phase between two signals. Waveform

Shape Analysis: Oscilloscopes can help analyze the waveform shape of a signal to detect the presence of distortion or unusual waveforms.

Gain: An oscilloscope can help you measure the voltage gain of an amplifier circuit. By comparing the amplitude of the input signal to the output signal, you can calculate the voltage gain.

Frequency Response: An oscilloscope can be used to observe the response of an amplifier circuit at different frequencies. By changing the frequency of the input signal and observing the output, you can understand the bandwidth and frequency characteristics of the amplifier circuit.

Phase Response: An oscilloscope can help you measure the phase response of an amplified circuit. This is important for understanding the time delay of a signal in a circuit.

Distortion Analysis: Oscilloscopes can be used to detect signal distortions such as aberrations, shear, and cross-distortion. This helps determine the linear performance and accuracy of an amplifier circuit.

Cutoff Frequency: By varying the frequency of the input signal, you can use an oscilloscope to observe the behavior of an amplifier circuit around the cutoff frequency. This is especially important for filtered amplifier circuits. Stability Analysis: An oscilloscope can help you observe the stability of a circuit, especially for feedback circuits. You can check if the output is stable and avoid oscillations or overshoots caused by instability.

Noise Analysis: Oscilloscopes can be used to detect noise in amplification circuits. This is important for high-sensitivity applications and low-noise circuit design.

Overload Detection: Oscilloscopes can be used to see if an amplifier circuit is overloaded when the input signal is significant. This is helpful to ensure that the circuit can handle signals of various input amplitudes.

Swing Rate: By observing the fastest rise time and the quickest fall time of the output signal, you can evaluate the fast response performance of the circuit.

5.2 Measuring Digital Signals

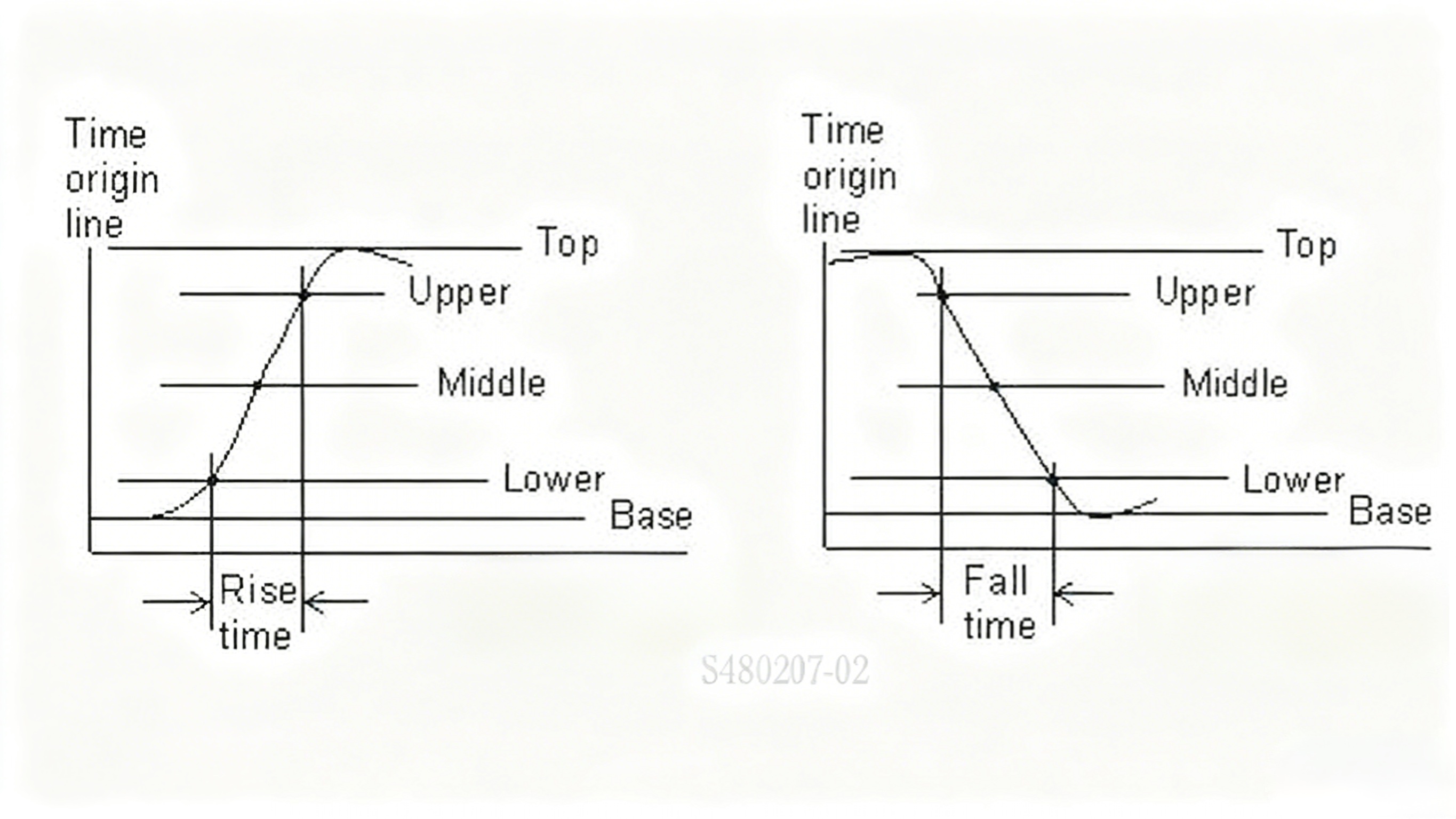

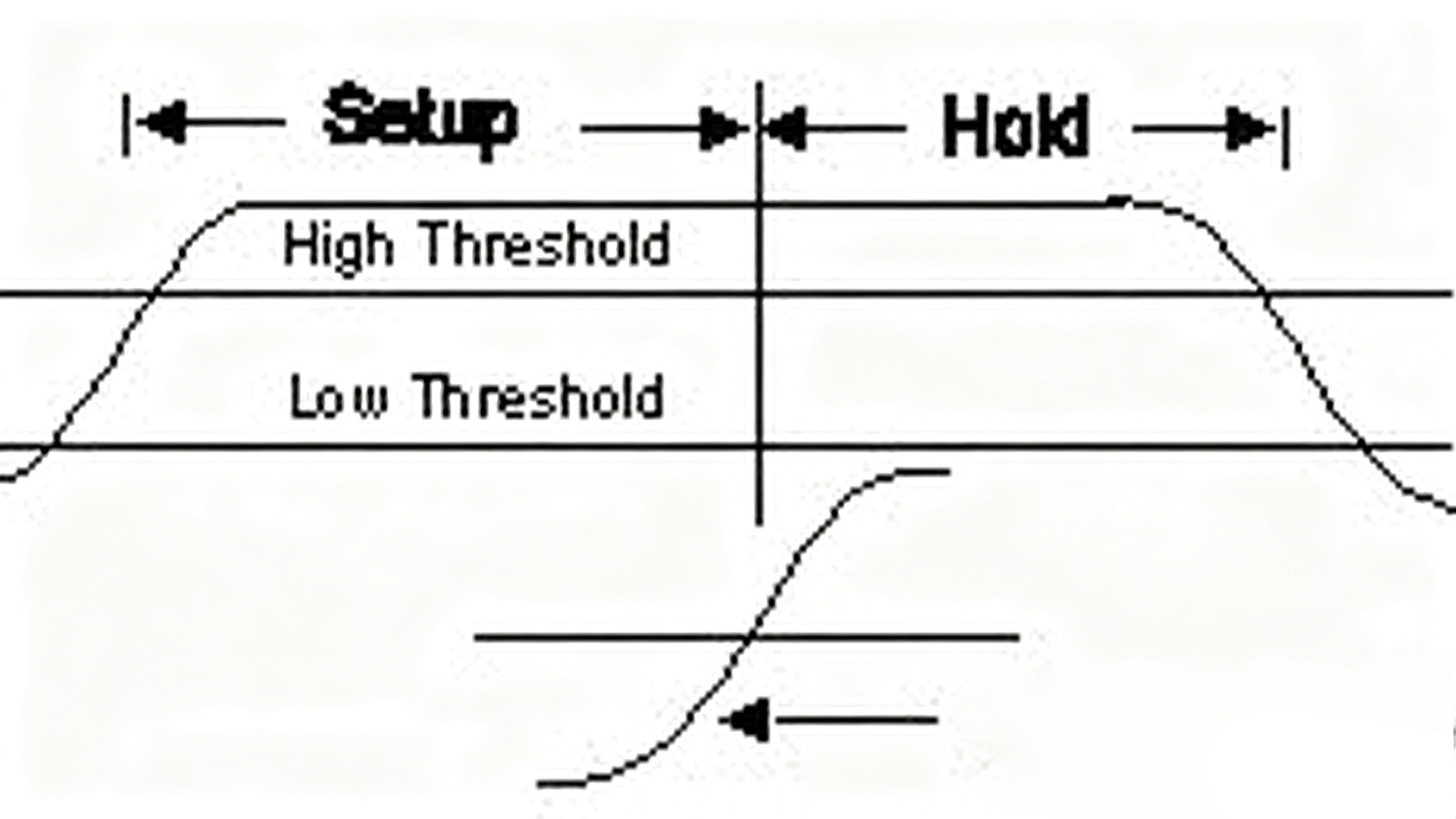

Rise Time: The rise time is the time on the upper threshold minus the time on the lower threshold of the edge you are measuring. The fall time is similar, i.e., the time on the lower threshold minus the time on the upper threshold of the edge you are measuring.

Pulse Width: The pulse width is the time from the middle threshold of the first rising edge to the middle threshold of the next falling edge.

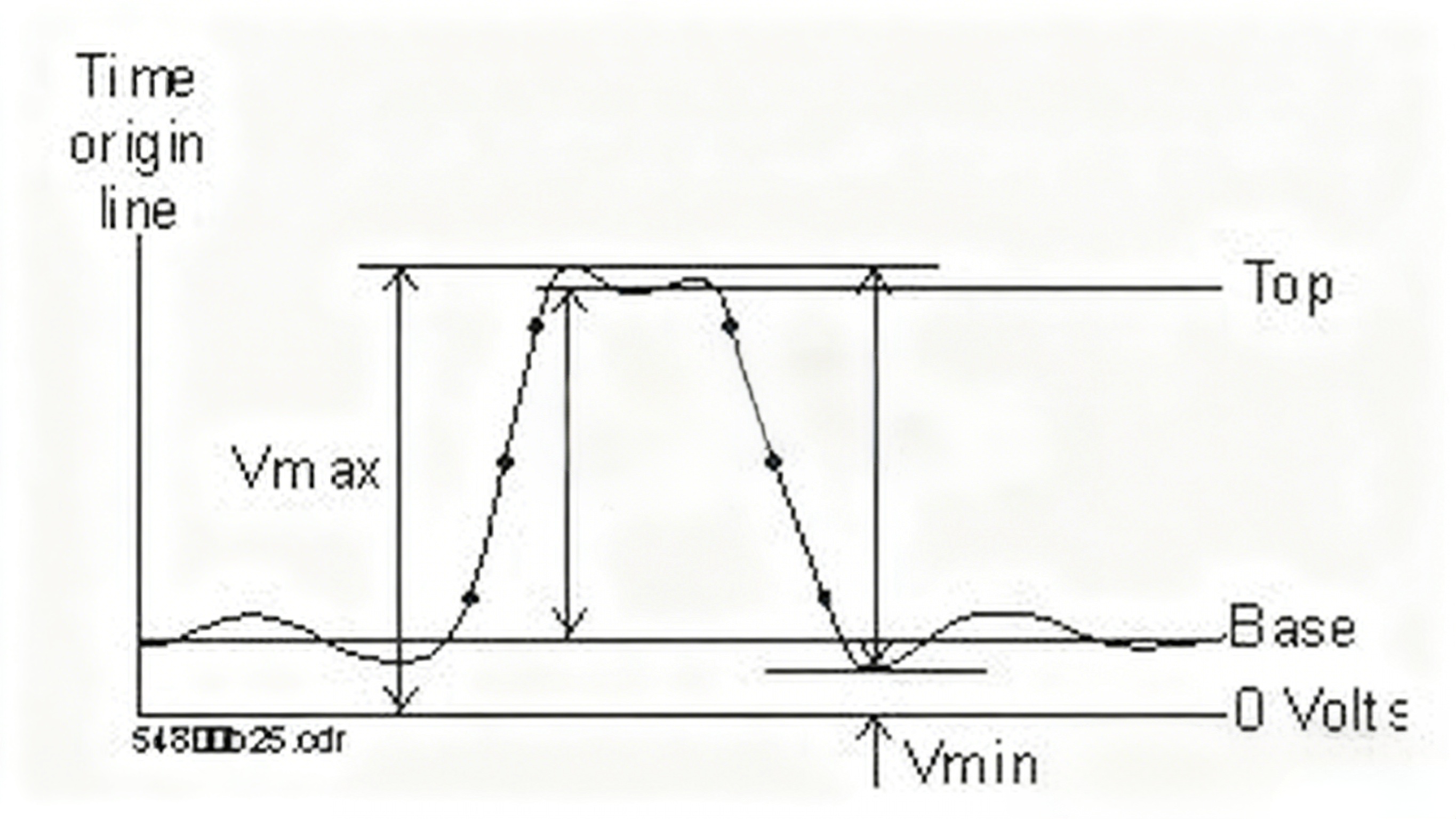

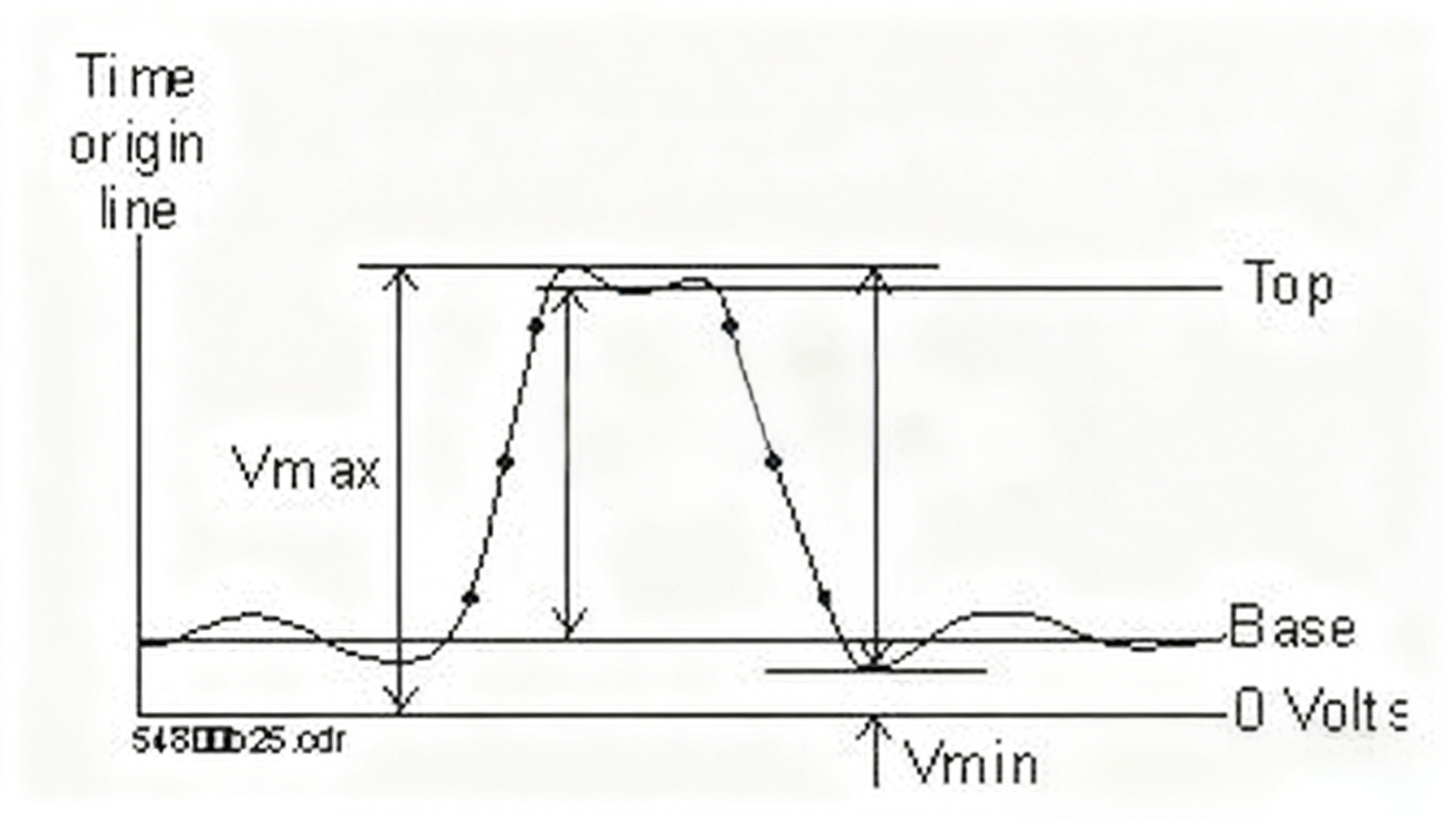

Amplitude and other voltage measurements: This is a measurement of the amplitude of the waveform display. Typically, you can also measure Peak to Peak Voltage, Maximum Voltage, Minimum Voltage, and Average Voltage.

Period / Frequency: The period is defined as the time between two consecutive crossing point voltages at the center threshold. Frequency is defined as 1/period.

Establishment and Hold Time: The establishment time is the minimum amount of time that the data needs to remain stable before the clock touch arrives. The hold time is the minimum amount of time that the data needs to remain stable after the clock trigger event arrives.

Eye Diagram: An eye diagram is simply a series of pulses (000,001,010,011, 100, 101,110,111) received at the receiving end that are simultaneously superimposed on a high-speed oscilloscope to form an eye diagram. With the addition of an eye diagram template, signals can be quickly evaluated to see if they meet bus requirements or system requirements.

There are many other measurements on the oscilloscope, such as duty cycle, offset, noise, jitter, and other parameters. Here are just a few basic measurement concepts.

Traditionally, oscilloscopes measure parameters in the time domain. However, with the development of technology, oscilloscopes have diversified, allowing some to also measure parameters in the frequency domain.

This is particularly useful in power supply integrity and EMC analysis, where the data is often converted into a time domain signal frequency domain curve for analysis. Observe what frequency band problems, and then "the right medicine" to solve the problem.

5.3 Power Supply Test

(1) ripple and noise test

Switching power supply ripple refers to the superimposed ripple on the output voltage of the switching power supply, with a frequency and switching frequency consistent with the amount of AC generated by the current ripple of the switching power supply, as influenced by the capacitor's ESR. Noise is generally referred to as the full bandwidth of the output voltage superimposed on the AC quantity.

When measuring ripple and noise, you need to use the isolator + coaxial cable, and the capacitance of the isolator needs to be determined according to the switching frequency.

Ripple measurement: Use a coaxial cable to lead the output from the power module to the spacer, and then connect to the oscilloscope through the coaxial cable. Oscilloscope settings include 50 ohms of impedance, AC coupling, and a bandwidth limited to 20MHz, followed by measurements and readings. The measured waveform generally approximates a triangular waveform.

Noise measurement: Cancel the bandwidth limit of the oscilloscope, and then carry out measurements and readings with the rest of the configuration unchanged.

(2) Power loop test

In reality, the feedback loop often plays a role in stabilizing the static operating point of the circuit, so we can not simply disconnect the loop to measure the loop gain. After the feedback loop is disconnected, the circuit is saturated directly at the output because of input misalignment, etc., and no meaningful measurements can be made in this case.

To overcome this problem, we must make measurements with the loop closed, and one possible means of doing this is loop injection. The figure below illustrates a typical loop injection method. To minimize error, we have special requirements for selecting the injection point, typically ensuring that the impedance looking in at one end is significantly greater than the impedance looking in at the other end. A preferred injection point is between the outputs and the feedback network, and other injection points, such as between the error amplifier and the power transistor, are also feasible.

To maintain a closed loop, we insert a tiny resistor at the injection point, allowing the injected signal to enter the loop without breaking it. The value of this injection resistor should be small enough, usually much less than the equivalent impedance of the feedback network, to ensure that the effect of the injection resistor on the feedback loop is negligible. Picotest recommends using an injection resistor of 4.99 Ω when using a J2100A transformer or the Siglent SAG1021I directly. Alternatively, an appropriately large injection resistor is also possible. Of course, a larger injection resistor is also possible.

On the other hand, since the injection resistor is connected in parallel with the injection transformer, a smaller injection resistor reduces the lower frequency limit of the transformer's operation, which is useful when very low frequencies are to be measured. In principle, the injection of the signal must not affect the static operating point of the loop.

To solve the problem of a common ground between the signal source and the DUT in real circuits, it is often necessary to use an injection transformer. Alternatively, you can directly use a signal source with isolation.

6. Getting Started

6.1 Basic operation: connections, probes & measurement flow

(1) Step 1. Check packing items

① Check the shipping carton for damage. Retain damaged shipping cartons or cushioning materials until you have checked the integrity of the contents and the mechanical and electrical properties of the oscilloscope.

② Verify that the following items are not present in the oscilloscope packaging:

- Oscilloscope.

- Power cord.

- N2841A 10:1 10 MΩ passive probe, Qty = 2.

- Documentation CD.

- Front panel labeling (if a non-English language option is selected).

③ Check the oscilloscope.

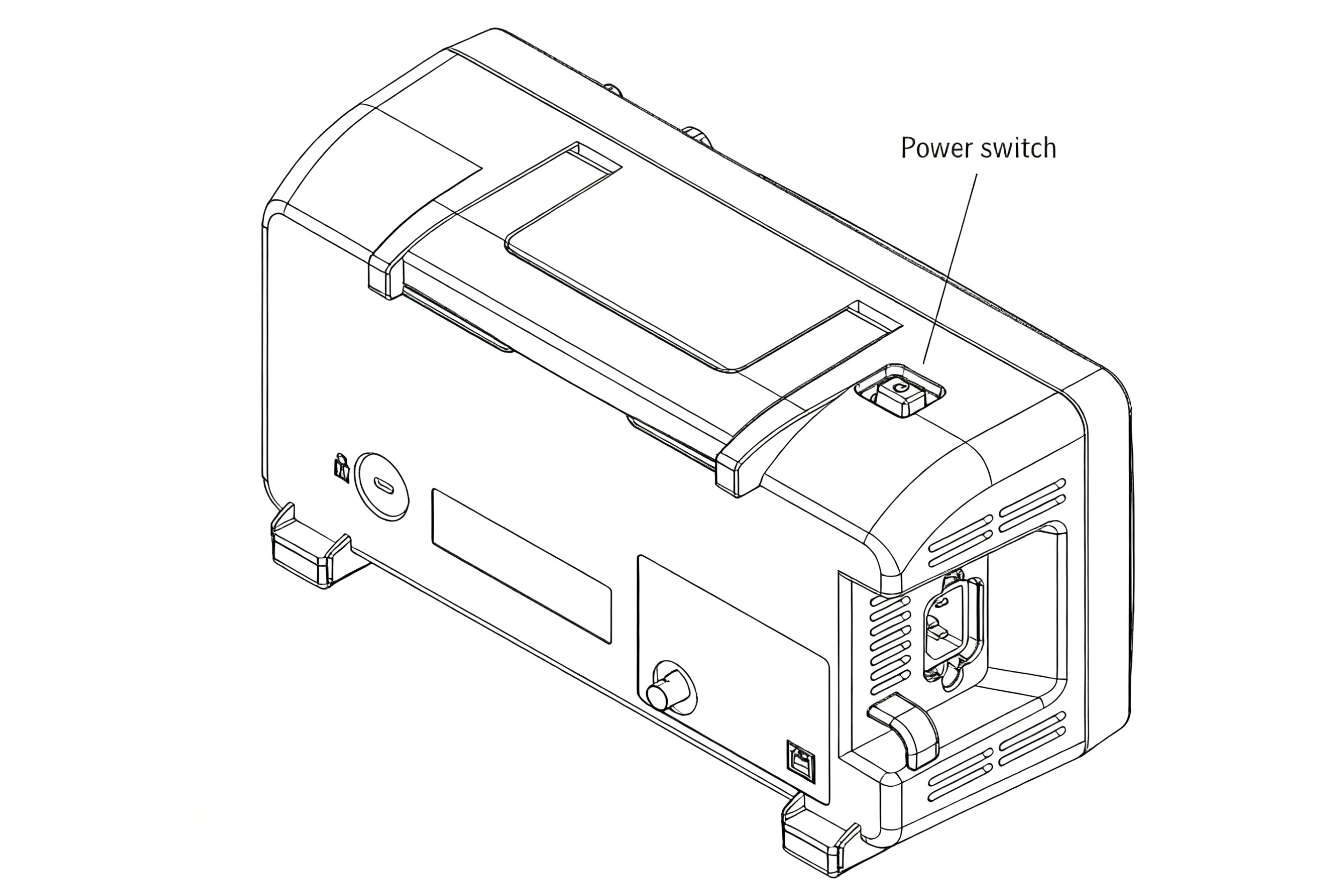

(2) Step 2. Turn on the oscilloscope power

The following steps (powering on the oscilloscope, loading default settings, and inputting waveforms) will provide a quick function check to verify that the oscilloscope is working correctly.

① Connect the power cord to the power supply. Use only the power cord designed for the oscilloscope. Use a power supply that provides the required amount of power.

The table shows the power requirements

Table1: Power Rating

|

Name

|

Typical Value

|

|

Power Rating

|

Maximum power is 50 W

100 - 120 V/50/60/400 Hz, ±10%

100 - 240 V/50/60 Hz, ±10%

|

Warning: To avoid electric shock, make sure the oscilloscope is adequately grounded.

The table shows the environmental characteristics

Table 2: Environmental Conditions

|

Name

|

Typical Value

|

|

Ambient Temperature

|

Operating: 0 °C to +50 °C

Non - operating: - 20 °C to +60 °C

|

|

Humidity

|

Operating: 80% RH at +40 °C for 24 consecutive hours (no condensation)

Non - operating: 60% RH at +60 °C for 24 consecutive hours (no condensation)

|

|

Altitude

|

Operating: 3,000 meters (9,842 feet)

Non - operating: 15,000 meters (49,213 feet)

|

|

Vibration

|

Keysight Classification GP and MIL - PRF - 28800F; Class 3 random vibration

|

|

Shock

|

Keysight Classification GP and MIL - PRF - 28800F; (30 grams during operation, half - sine, duration 11 milliseconds, 3 shocks per axis along the main axis direction. Total of 18 shocks)

|

|

Pollution Degree 2

|

Generally only produces dry, non - conductive pollution.

Temporary conductivity due to condensation must be expected.

|

|

Indoor Use

|

For indoor use only.

|

② Turn on the oscilloscope's power supply.

(3) Step 3. Load Default Oscilloscope Settings

You can load the factory default settings at any time to restore the oscilloscope to its original settings.

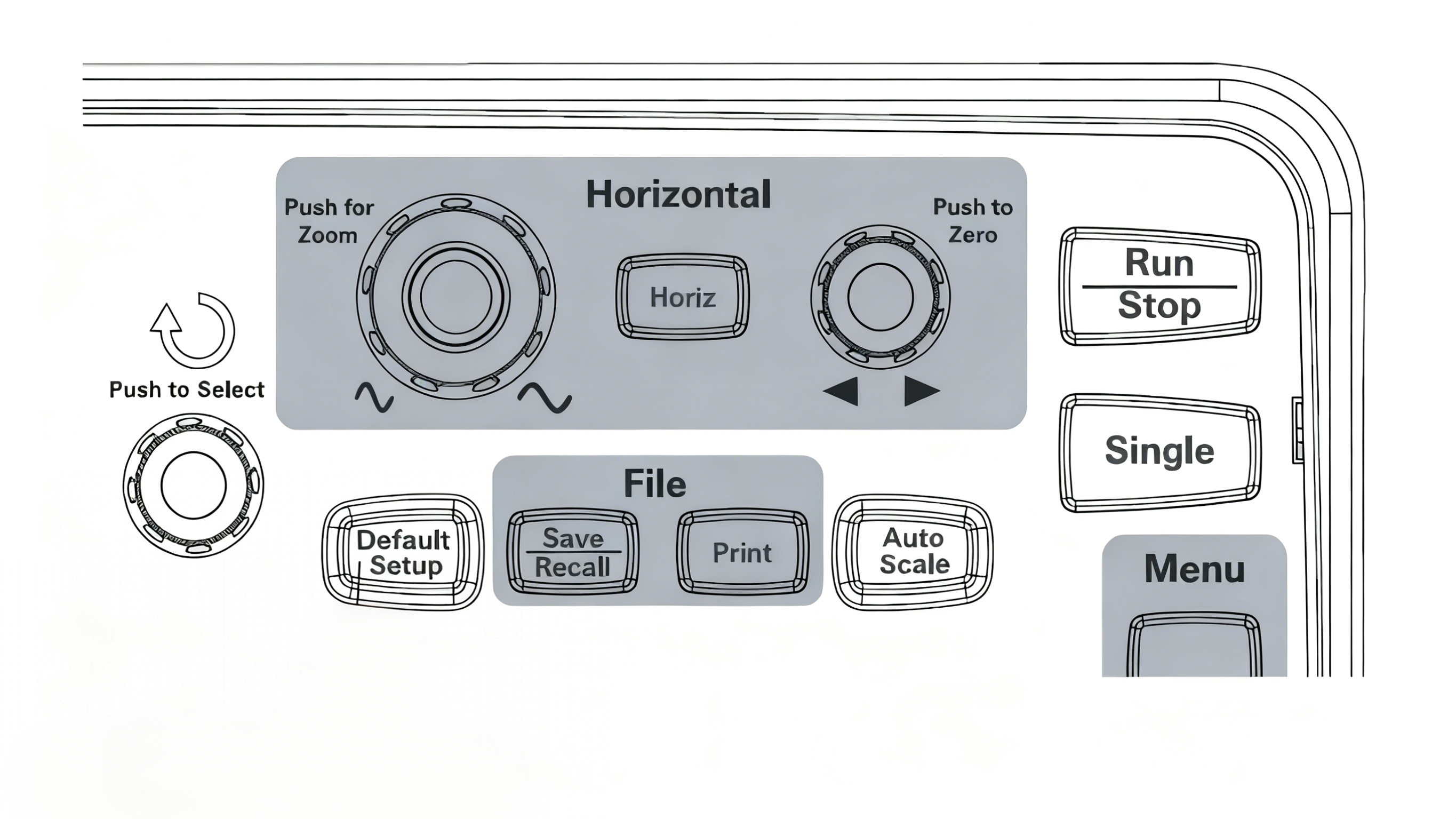

① Press the Default Setup [Default Setup] key on the front panel.

② While the Default menu is displayed, press Menu On/Off to close the menu. (You can use the Undo softkey in the Default menu to cancel the default setting and return to the previous setting.

(4) Step 4. Inputting Waveforms

Input the waveform into the channel of the oscilloscope. Input the probe compensation signal from the front panel of the oscilloscope using one of the supplied passive probes.

To avoid damaging the oscilloscope, make sure that the input voltage on the BNC connector does not exceed the maximum voltage (maximum 300 Vrms).

When measuring voltages above 30 V, use a 10:1 probe.

(5) Step 5. Using Auto Setup

The oscilloscope has an auto setup function that automatically sets the oscilloscope controls for the input waveform present.

Auto setup requires a waveform with a frequency greater than or equal to 50 Hz and a duty cycle greater than 1%.

① Press the [Auto Scale] key on the front panel.

② While the Auto menu is displayed, press Menu On/Off to close the menu.

The oscilloscope will open all the channels to which the waveform has been applied and set the vertical and horizontal scales accordingly. It also selects the time base range according to the trigger source. The trigger source chosen is the highest numbered channel to which the waveform has been applied.

(You can use the Undo softkey in the Auto menu to cancel the automatic setting and return to the previous setting.)

The oscilloscope has been configured for the following default control settings:

Table for Auto Setup Default Settings

|

Menu

|

Settings

|

|

Horizontal Time Base

|

Y - T (Amplitude vs. Time)

|

|

Acquisition Mode

|

Standard

|

|

Vertical Coupling

|

Adjust to AC or DC according to the waveform.

|

|

Vertical "V/div"

|

Adjust

|

|

Volts/Div

|

Coarse Adjust

|

|

Bandwidth Limit

|

Off

|

|

Waveform Inversion

|

Off

|

|

Horizontal Position

|

Relative to Center

|

|

Horizontal "s/div"

|

Adjust

|

|

Trigger Type

|

Edge

|

|

Trigger Source

|

Automatically measure the channel with input waveform.

|

|

Trigger Voltage

|

Mid - point Setting

|

|

Trigger Mode

|

Auto

|

|

Trigger Coupling

|

DC

|

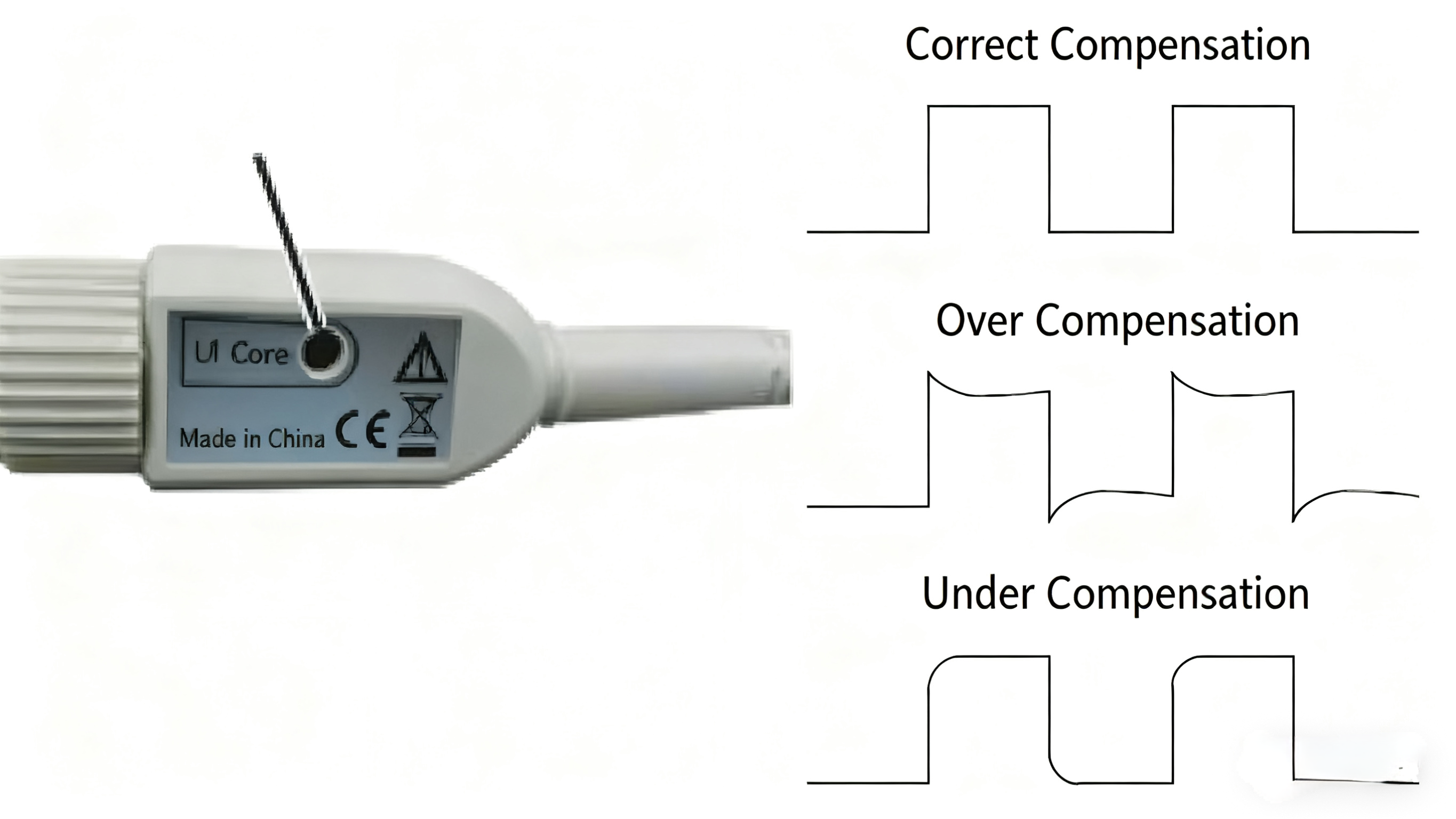

(6) Step 6. Compensate Probe

Compensate the Probe to match the input channel. The Probe should be compensated whenever the Probe is connected to the input channel for the first time.

Oscilloscope Low Frequency Compensation

For the supplied passive Probe:

① Set the " Probe" menu attenuation to 10X. If using a probe hook tip, securely insert the hook tip into the Probe to ensure proper connection.

② Connect the probe tip to the Probe Compensation connector and connect the ground lead to the Probe Compensator ground connector.

③ Press the Auto Setup [Auto Scale] front panel key.

④ If the waveform does not look like the correctly compensated waveform shown in Figure 4, use a non-metallic tool to adjust the Low Frequency Compensation Adjustment on the Probe to obtain as flat a square wave as possible.

Oscilloscope Low-Frequency Compensation Adjustment

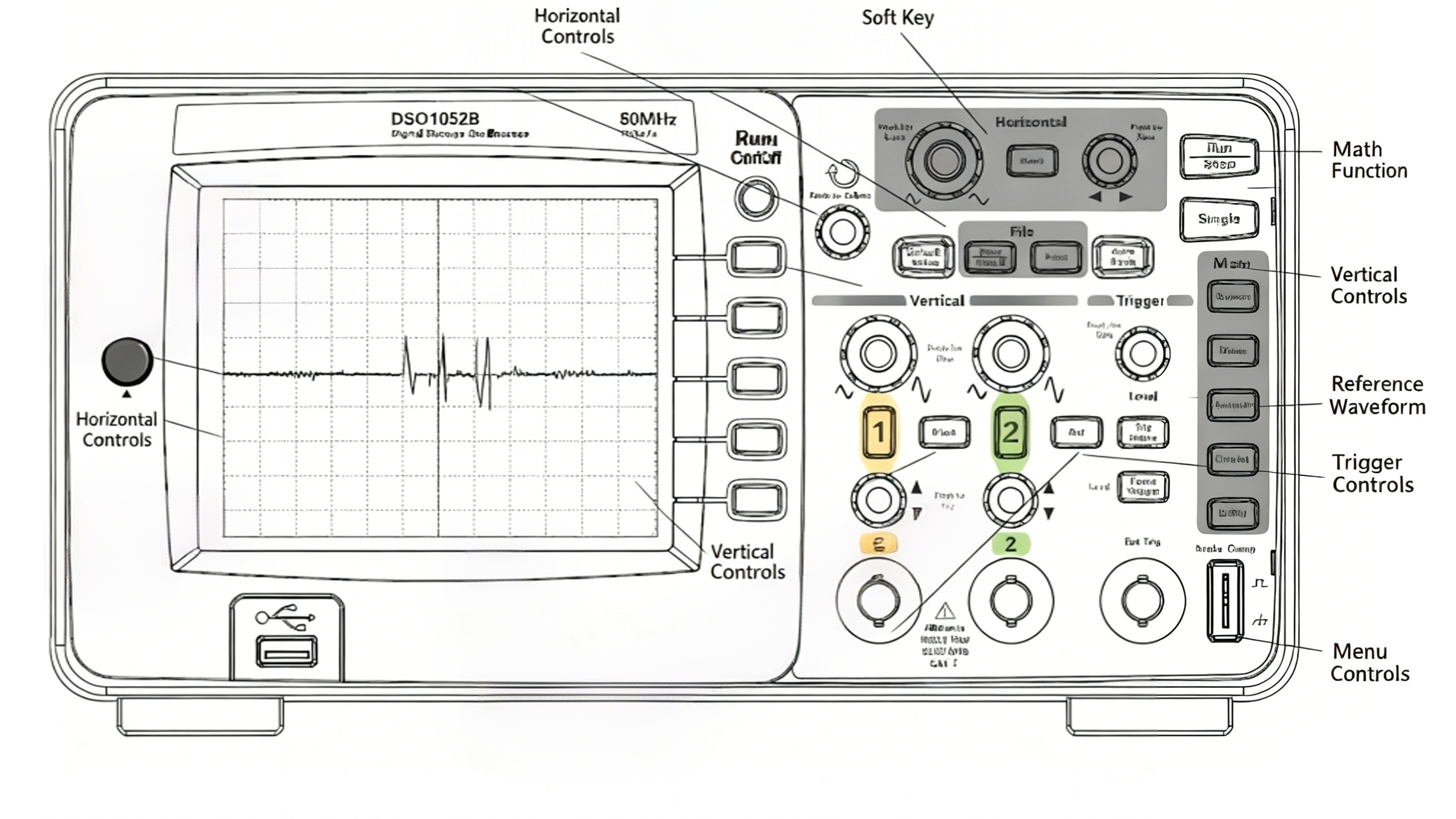

(7) Step 7. Familiarize Yourself with the Oscilloscope Front Panel Controls

Before using the oscilloscope, you should familiarize yourself with the front panel controls.

The front panel has knobs, keys, and softkeys. The knobs are most often used to make adjustments. Use the keys to run the controls and change other oscilloscope settings through the menus and softkeys.

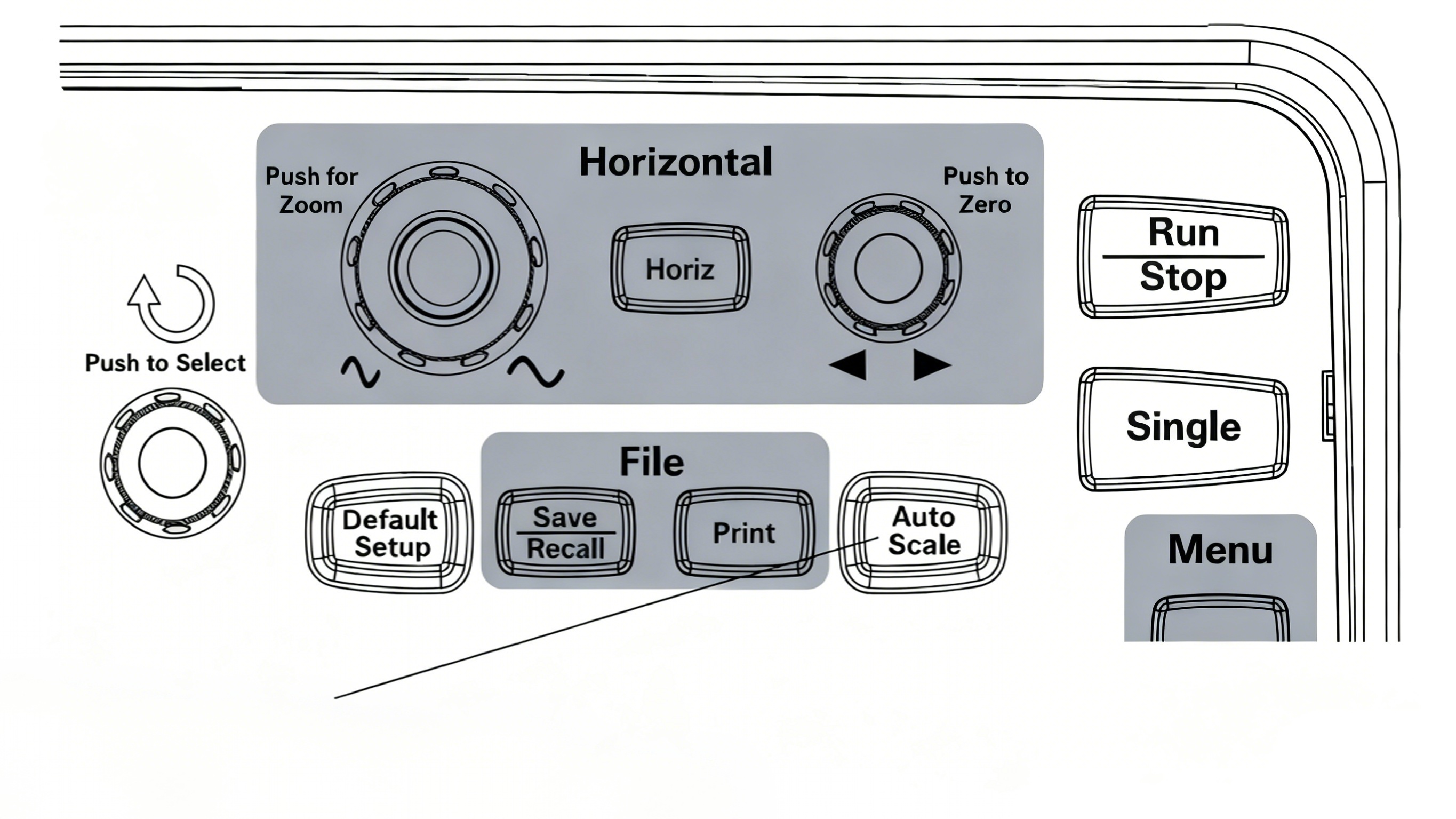

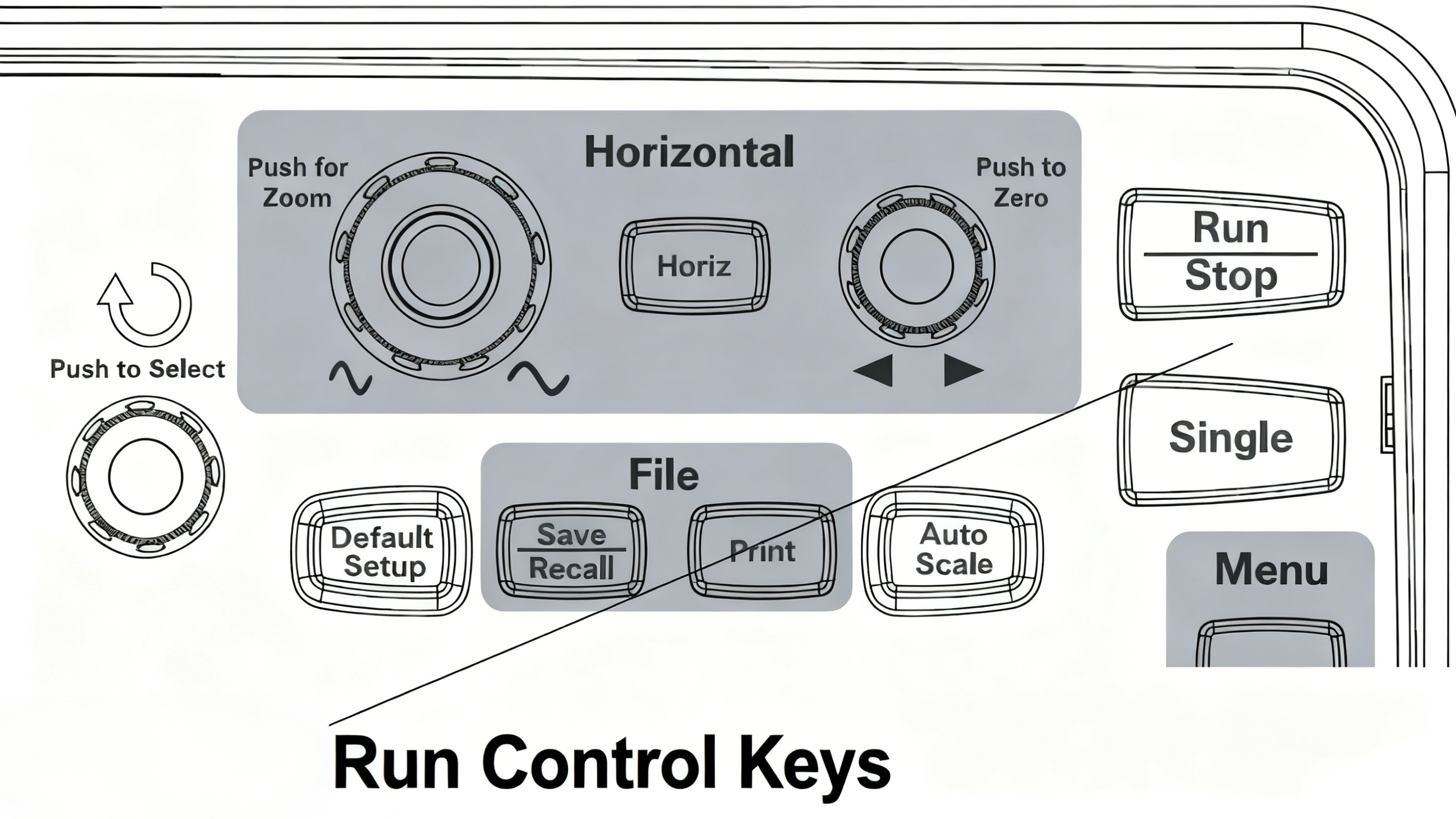

The oscilloscope front panel knobs, keys, and softkeys are defined below:

Oscilloscope Front Panel Controls

|

Controls

|

Include the following knobs and keys

|

|

Input Knob

|

Used to adjust defined controls.

|

|

Setup Controls

|

Front - panel keys for Auto Scale and Default Setup.

|

|

File Controls

|

Front - panel keys for Save/Recall and Print.

|

|

Horizontal Controls

|

Position knob, front - panel key for Horiz, and adjustment knob.

|

|

Run Controls

|

Front - panel keys for Run/Stop and Single.

|

|

Menu Controls

|

Front - panel keys for Cursors, Meas, Acquire, Display, and Utility.

|

|

Trigger Controls

|

Level knob, front - panel key for Menu, and front - panel key for Force Trigger.

|

|

Vertical Controls

|

Vertical position knob, vertical adjustment knob, channels (such as [1], [2], etc.), front - panel keys for Math and Ref.

|

|

Soft Keys

|

There are five gray keys from top to bottom on the right side of the screen, which can select adjacent menu items in the currently displayed menu.

|

Definitions of Oscilloscope Front Panel Knobs, Keys, and Softkeys

Front Panel Labeling in Different Languages

If the Language other than English option is selected, a front panel decal is available for the selected Language.

To install the front panel decal

① Insert the tab on the left side of the sticker into the appropriate slot on the front panel.

② Gently press the sticker onto the knobs and buttons.

③ When the decal is aligned with the front panel, insert the tab on the right side of the decal into the slot on the front panel. 4 Spread the decal flat. It should be fixed on the front panel.

(8) Step 8. Familiarizing Yourself with the Oscilloscope Display

Using the Oscilloscope Softkey Menu

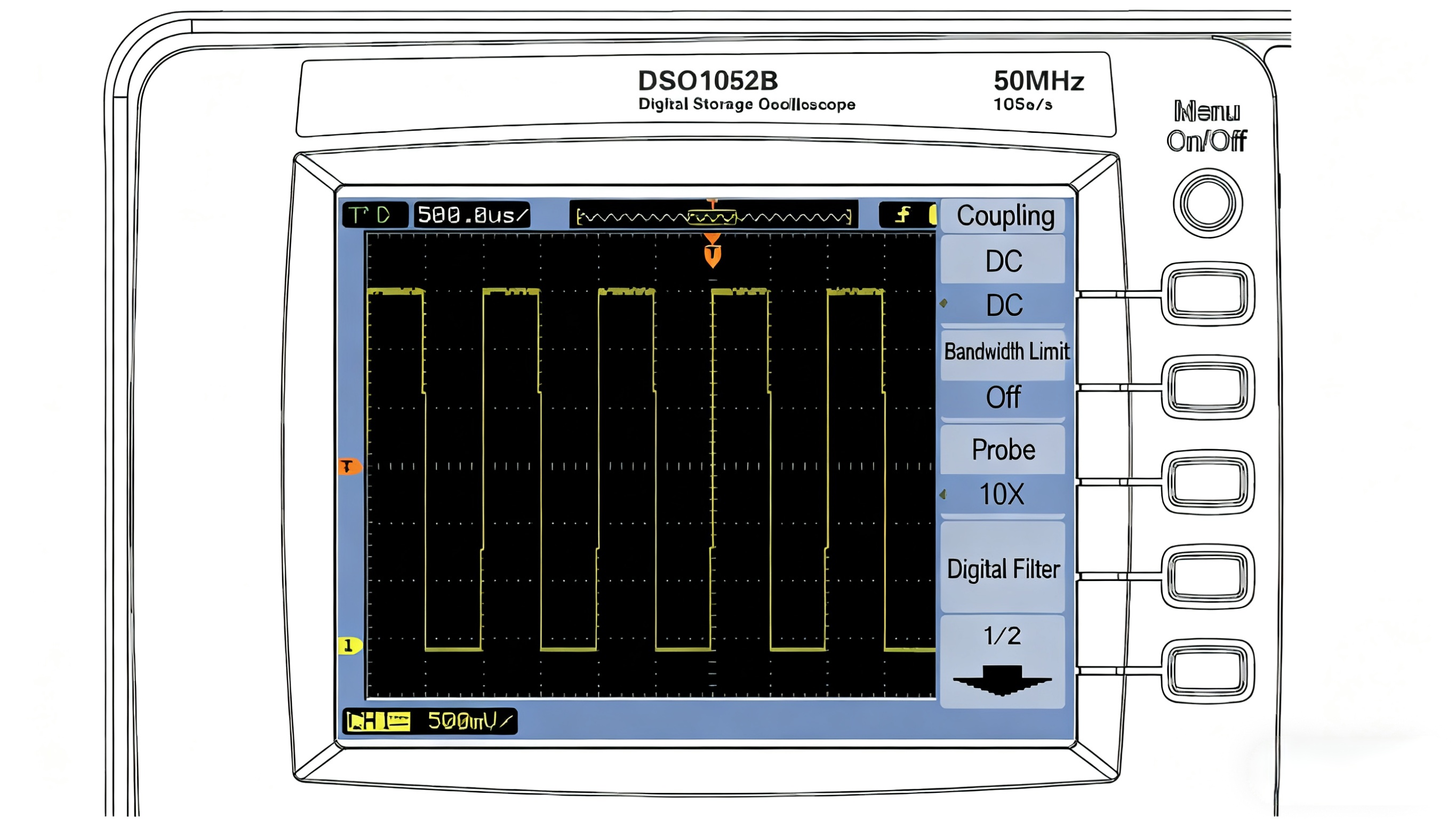

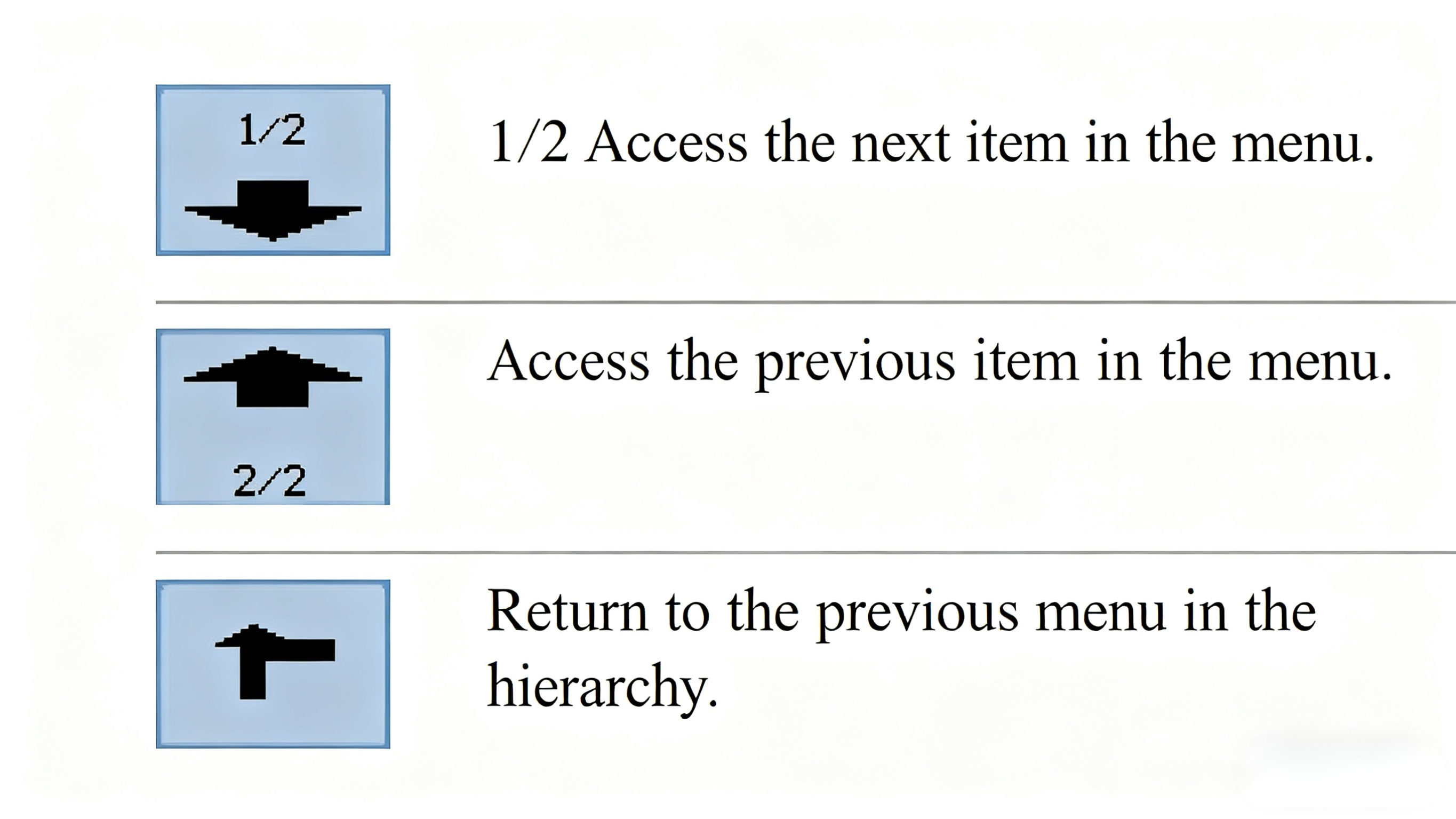

When one of the oscilloscope front panel keys opens a menu, five softkeys can be used to select items from the menu. Some commonly used menu options are listed below:

Menu On/Off [Menu On/Off] The front panel keys close the menu or open the last accessed menu again.

Use the Menu Hold item in the Display menu to select how long the menu is displayed.

(9) Step 9. Using the Run Control Keys

There are two front panel keys for starting and stopping the oscilloscope acquisition system: Run/Stop and Single.

When the Run/Stop key is green, the oscilloscope is acquiring data. To stop data acquisition, press Run/Stop. After stopping, the last acquired waveform will be displayed.

When the Run/Stop [Run/Stop] key is red, data acquisition has stopped. To start data acquisition, press the Run/Stop [Run/Stop].

To capture and display a single acquisition (regardless of whether the oscilloscope is running or stopped), press the Single [Single] key.

[Single]. After a single acquisition has been captured and displayed, the Run/Stop key is red.

(10) Step 10. Accessing the Built-in Help

The oscilloscope has built-in quick help information. To access the built-in help:

Press and hold the front panel keys, softkeys, and pushable knobs for which you want to access their quick help information. The built-in help is available in 11 different languages.

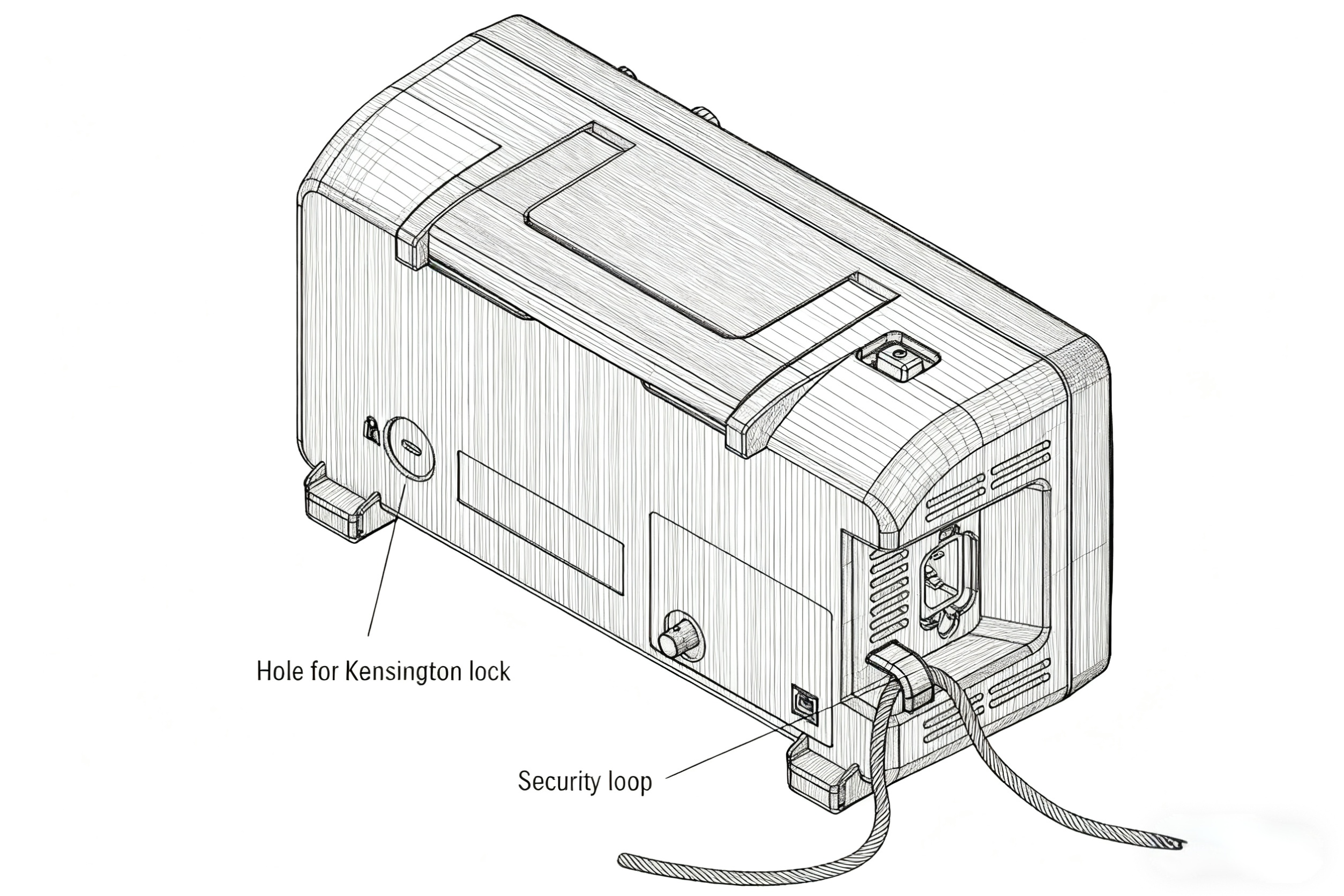

(11) Step 11. Fixed Oscilloscopes

To secure the 1000B Series oscilloscopes in place, use the anti-theft locking holes or safety rings.

6.2 Troubleshooting examples (step-by-step with screenshots)

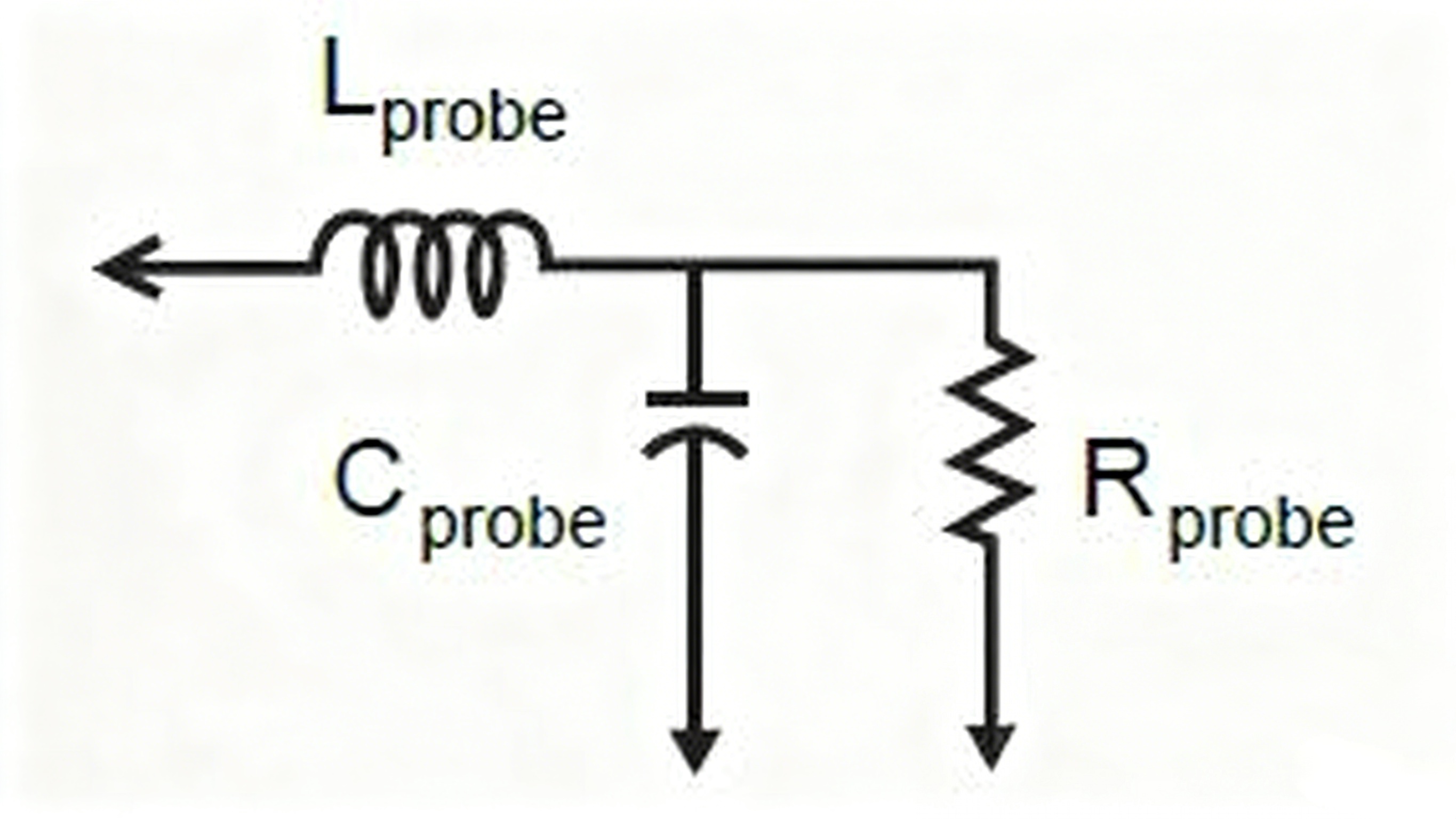

Ideally, all probes should be a wire that does not cause any interference with the device under test and, when connected to your circuit, has an infinite input resistance, zero capacitance, and zero inductance. This will accurately replicate the signal under test. The reality, however, is that the Probe introduces a loading effect into the circuit. Resistive, capacitive, and inductive components on the Probe may alter the response of the circuit under test.

Learn about the errors that can be encountered in testing and how measurements can be improved through better operation. The electrical characteristics of the Probe can affect the measurement results and the operation of the circuit. Taking steps to ensure that these effects are within acceptable limits is a critical step for successful measurements. The following are seven common errors when using an oscilloscope:

(1) Error 1: Failure to calibrate the Probe

Probes are calibrated after they leave the factory, but they are not calibrated for the oscilloscope front end. If they are not calibrated on the oscilloscope input, then correct measurements cannot be obtained.

Active Probes

If active probes are not calibrated for the oscilloscope, you will see differences in vertical voltage measurements and rising edge timing (and possibly some distortion) during testing. Most oscilloscopes have a reference or auxiliary output and an operating guide to guide the engineer through the calibration of the Probe.

The figure above shows the 50 MHz signal input to the oscilloscope from the SMA cable and adapter on channel 1 (yellow trace). The green trace is the same signal input to the oscilloscope via the active Probe on Channel 2. Note that the generator output on Channel 1 is 1.04 Vpp (volts peak-to-peak) and the signal detected on Channel 2 is 965 mV (millivolts). Also, the offset between channel one and channel 2 is up to 3 ms (milliseconds), so the rise times cannot be lined up at all.

Passive Probes

The variable capacitance of the Probe can be adjusted to match the compensation to the oscilloscope input being used ideally. Most oscilloscopes have a square wave output that can be used for calibration or reference. Probe this connection and check that the waveform is square. Adjust the variable capacitance as necessary to eliminate any downshoot or overshoot.

If this Probe is calibrated, the results will be much improved. The results after proper amplitude and offset calibration can be seen in the graph. The amplitude is now enhanced to 972 mVpp, the offset is corrected, and the two rise times remain consistent.

(2) Error 2: Increased Probe Load Effect

As soon as a probe is connected to an oscilloscope and it is brought into contact with the device to be measured, the Probe becomes part of the circuit. The resistive, capacitive, and inductive load effects that the Probe applies to the device under test can affect the signal that the engineer sees on the oscilloscope screen. These load effects may change the operating state of the circuit under test. Understanding these load effects helps engineers avoid selecting the wrong Probe for a particular circuit or system. Probes have resistance, capacitance, and inductance characteristics as shown in the figure.

It may be necessary to find ways to add long leads or wires to reach probes where the surroundings are too tight. However, adding attachments or probes to a probe can reduce bandwidth, increase loading effects, and consequently cause the frequency response to no longer be flat.

Use the shortest possible leads to maintain the bandwidth and accuracy of the Probe. Typically, the longer the input wire or leads to the Probe, the more the bandwidth is reduced. Narrower bandwidth measurements may not be affected as much. However, when making wider bandwidth measurements, especially above 1 GHz, you need to be careful in choosing the probes and accessories you use. As the probe bandwidth decreases, you lose the ability to measure fast rise times.

It is also a good idea to use shorter ground leads because the longer they are, the more inductance they introduce. Keep ground leads as brief as possible and as close to the system ground point as possible to ensure repeatable and accurate measurements.

Tip: If you must add wire to the Probe to reach a hard-to-reach probe point, it is a good idea to add a resistor to the Probe to dampen the resonance caused by the added wire. You may not be able to solve the bandwidth limitation problem when adding long leads, but you can flatten the frequency response. To determine the size of the resistor to be used, probe a known square wave, such as the reference square wave provided on the oscilloscope. If the resistor is set correctly, you will see a clean square wave (except that its bandwidth may be limited). If the signal is ringing, increase the size of the resistor. Single-ended probes require only one additional resistor at the Probe. If you are using a differential probe, add a resistor to each lead.

(3) Error 3: Not Utilizing Your Differential Probe to Its Fullest Potential

Many people think that they only use differential probes when probing differential signals. Is it possible to use differential probes when probing single-ended signals? Yes, it is. If used properly, this will save a lot of time and money in testing and improve the accuracy of your measurements. Maximize the use of differential probes to get the best signal fidelity possible.

Differential probes can make the exact measurements as single-ended probes. Because differential probes have common-mode rejection on both inputs, the noise in the differential measurement result is significantly reduced. This allows you to see a better representation of the signal from the device under test without being misled by the random noise added by the Probe.

The blue single-ended measurement signal and the red differential measurement signal are shown in the figure. The blue single-ended measurement exhibits significantly more noise than the red differential measurement, primarily due to the single-ended probe's lack of standard mode correction.

(4) Error 4: Choosing the wrong current Probe

High-current and low-current measurements do not require the same level of detail to be captured. It is up to the engineer to know which current Probe is the better choice for the application and what troubles may be encountered by using the wrong Probe.

Large Current Measurements

If a clamp-on probe is used to measure large currents (10A - 3000A), the device to be measured must be small enough for the clamp-on probe to clamp onto it. If the device is too large for the clamp-on probe to hold, the engineer may need to add extra wires to the probe clamp, which will alter the device's characteristics under test. A better approach is to use the right tool for the job.

The best solution is to use a high-current probe with a flexible loop probe tip. This flexible loop can be wrapped around any device. This Probe is called a Rogowski coil. It allows engineers to probe devices without adding components of unknown characteristics, allowing measurements to maintain a high degree of signal integrity. They also enable engineers to measure large currents from mA levels to hundreds of kA. Note that they only measure AC so that the DC component will be isolated. They are also less sensitive than some current probes. This is usually not a problem for large current measurements. But when measuring small currents, sensitivity and the ability to see the DC component become essential. Remember that what works for one measurement does not necessarily work for another.

Small Current Measurements

Dynamic range can vary greatly when measuring current from a battery-powered device. If the battery-powered device is idle or only handling a small number of background tasks, its current peaks will be small. When the device is switched to a more active state, the current peaks increase dramatically. Using an oscilloscope setup with a large vertical scale, engineers can measure large signals, but small current signals will be masked by measurement noise. On the other hand, if you use a smaller vertical scale setting, then large signals will clip, and measurements will be distorted and invalidated.

The current Probe you choose should be capable of measuring a wide range from μA to A and utilize multiple amplifiers to detect both small and large current deviations simultaneously. The two variable gain amplifiers in the Probe allow you to set up a zoomed-in view to see small current fluctuations and a zoomed-out view to see large current spikes at the same time (see figure below).

(5) Error 5: Incorrectly Handles DC Bias During Ripple and Noise Measurements

A small AC signal on a larger DC signal forms ripple and noise on a DC power supply. When the DC bias is significant, it may be necessary to use a larger voltage-per-cell setting on the oscilloscope to display the signal on the screen. This reduces the sensitivity of the measurement and increases the noise compared to a small AC signal. This means that an accurate representation of the AC portion of the signal cannot be obtained during testing.

Suppose a DC isolation capacitor is used to solve this problem. In that case, it will inevitably block some of the low-frequency AC content, preventing the engineer from observing the changes in the signal as it passes through the components on the device.

Using a power probe with a larger bias allows the waveform to be placed in the middle of the screen without removing the DC bias. This allows the entire waveform to be displayed on the screen while keeping the vertical scale small and at amplification. These settings also allow details of transients, ripple, and noise to be viewed.

(6) Error 6: Unknown Bandwidth Limits

When making essential measurements, always select a probe with sufficient bandwidth. Insufficient bandwidth can distort the signal, making it difficult for engineers to make informed engineering test or design decisions.

The generally accepted formula for bandwidth calculation is: when evaluating the rising edge from 10% to 90%, the bandwidth multiplied by the rise time equals 0.35.

BW x Tr = 0.35

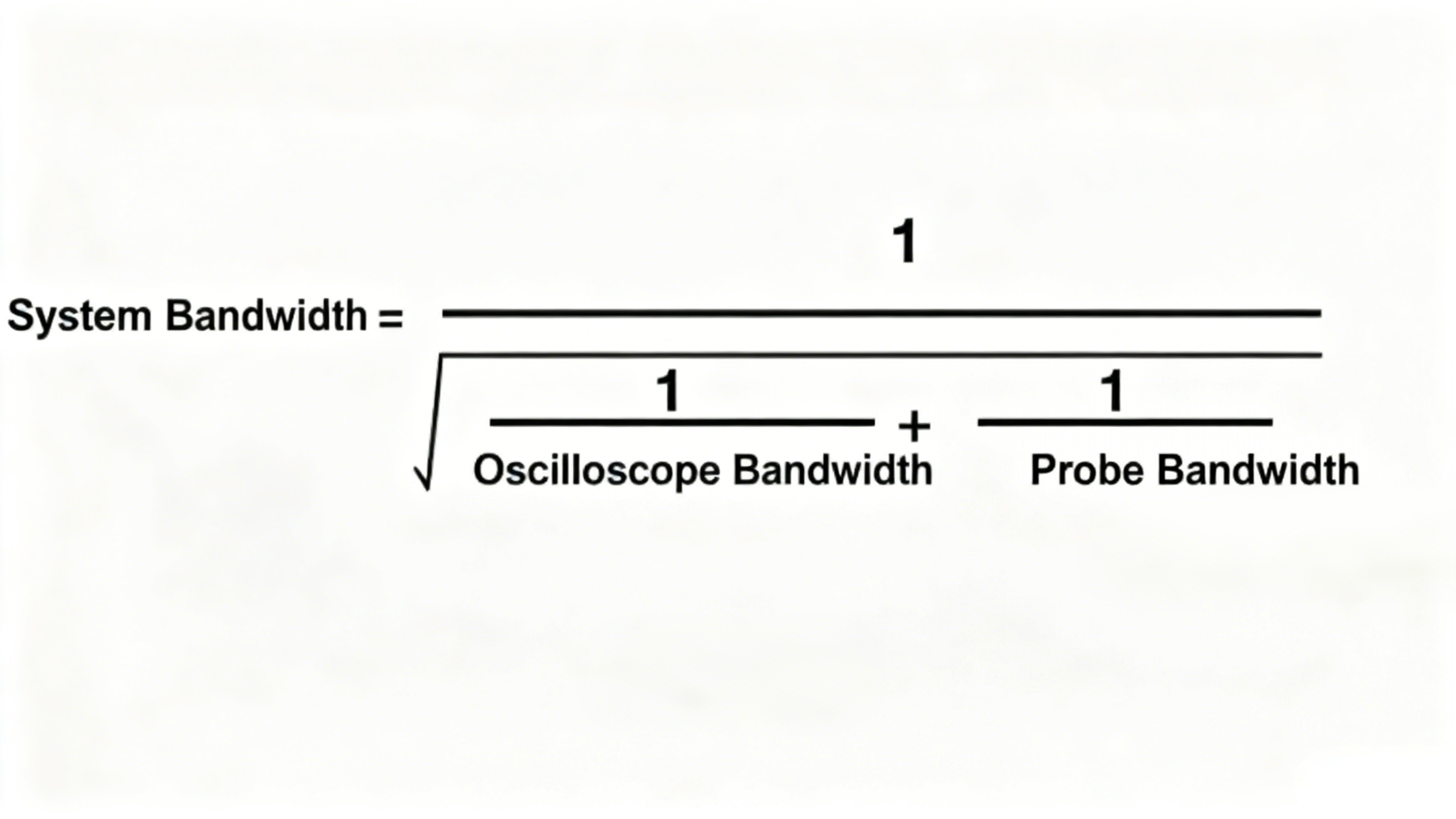

It is important to note that the overall system bandwidth is also an essential factor to consider. The bandwidth of both the Probe and the oscilloscope should be considered to determine the system bandwidth. The formula for calculating the system bandwidth is shown below.

For example, assume that the oscilloscope and probe bandwidths are both 500 MHz. Using the above formula, the system bandwidth would be 353 MHz. As can be seen, the system bandwidth is significantly reduced when compared to the two separate bandwidths of the Probe and oscilloscope.

Now, if the probe bandwidth is only 300 MHz and the oscilloscope bandwidth is still 500 MHz, then applying the above formula, the system bandwidth is further reduced to 257 MHz.

(7) Error 7: Masked Noise Effects

Probe and oscilloscope noise may cause the noise of the device under test to appear larger. Selecting a probe with the proper attenuation ratio for the engineer's application will reduce the noise added by the Probe and oscilloscope. As a result, the engineer will be able to obtain a more accurate signal and a clearer view of the device under test.

Many probe manufacturers describe probe noise as Equivalent Input Noise (EIN) and express it in Vrms. Higher attenuation ratios allow you to measure larger signals, but the downside is that the oscilloscope will detect these ratios and amplify both the signal and its noise. To see the practical results of this effect, the green trace in the figure shows the noise after amplification with a 10:1 probe.

7. Advanced features and specialized analysis

7.1 Advanced features: FFT, protocol decode, serial bus analysis

(1) FFT function

Intuitively, the time domain analysis of the oscilloscope is clearly visible, and the time domain analysis function is also the most essential function of the oscilloscope; testers are relatively familiar with the time domain analysis function. However, when further analysis of the signal is required, such as determining the proportion of harmonics and energy distribution, time domain analysis is insufficient. In this case, the utilization of oscilloscopes equipped with a Fast Fourier Transform (FFT) function to analyze the signal becomes particularly meaningful.

FFT is a potent analysis function. The digital oscilloscope has a typical application. Based on the advanced FFT analysis function, testers can accurately understand the signal introduced in the interference signal frequency, signal power spectrum, and signal frequency composition.

When the oscilloscope is switched to the FFT function, the horizontal axis is the frequency, unit (Hz); the vertical axis is the power (dB) or voltage (V). When using the FFT function of the oscilloscope, you need to pay attention to the following parameters: the number of sample points, spectral resolution, and sampling frequency.

Number of Sample Points: The number of points used to calculate the FFT.

Spectral resolution: the most minor frequency that the oscilloscope can resolve, i.e., the frequency interval between two neighboring frequency points.

Sampling frequency: the number of points collected per second.

Take the actual signal as an example. When the oscilloscope samples the digital signal, it can perform the FFT transform. Assuming that the sampling frequency is Fs, the signal frequency F, and the number of sampling points is N. The frequency of a point n is Fn. The frequency that can be resolved to Fn is related to the number of sampling points, which is calculated as follows: Fs/N, if the sampling frequency Fs is 1kHz and the number of sampling points is 1k, it can be resolved to 1Hz, that is to say, sampling the signal of 1 second and doing the FFT, the frequency resolution can be as accurate as 1Hz; if sampling 2 seconds and doing the FFT, the frequency resolution can be as precise as 1Hz; if sampling 2 seconds and doing the FFT, the frequency resolution can be as accurate as 1Hz. 1Hz; if the signal is sampled for 2 seconds and the FFT is done, the result can be precise to 0.5 Hz. If the frequency resolution is to be improved, the number of sampling points must be increased, i.e., the sampling time must be extended. Spectral resolution and sampling time are inversely related.

According to the Nyquist sampling theorem, the spectrum width after FFT can only be 1/2 of the original signal sampling rate, so the sampling frequency should be greater than 2 times the highest frequency of the signal to restore the original signal waveform. Therefore, a higher spectral resolution requires a longer sampling time, and a wider spectral distribution requires a higher sampling rate of the original signal. If we want a broader spectrum and higher resolution, the oscilloscope requires sufficient storage depth. In practice, we can follow the above method to select the appropriate oscilloscope with reference to the measured signal.

(2) Protocol decoding

Manual decoding of the serial bus according to the oscilloscope waveform display is both time-consuming and error-prone. In this relatively simple I2C signal, there may be a problem. Can you easily find the problem? Can you even tell what the signal represents? To decode this packet manually, look for the packet header, data bits, and packet tail. Confirm all data signal states (blue) against each other using the clock states (**) and convert them to hexadecimal values.

Manual decoding is compared here with the automatic decoding example. Simply defining which channels the clock and data are on and defining the thresholds for determining the logic values ("1" and "0") allows the oscilloscope to be informed of the protocol being transmitted over the bus. In a split second, the serial data can be decoded and displayed, illustrating the start, address, data, and end bits in the bus waveform display. Address and data values can be shown in hexadecimal or binary for the I2C bus.

(3) Serial bus analysis

The use of ordinary oscilloscopes can only perform general edge triggering and pulse width triggering; it is difficult to capture the complexity of the serial bus waveform. Instead, using an oscilloscope with a serial bus trigger function makes it easy to capture the desired serial data. Yokogawa's DLM2000 series digital oscilloscopes support the triggering of a variety of commonly used serial buses, including CAN/LIN/I2C/SPI/UART. They can even be triggered on user-defined non-standard serial buses. Depending on the structure of each bus, multiple trigger modes can be set. The more trigger modes, the better the ability to capture data.

In embedded systems, there are often two or even more serial bus structures at the same time. For example, in automotive electronics, CAN and LIN buses are frequently used simultaneously, and it is necessary to analyze whether the two bus communications are causing the problem. Most of the oscilloscopes with a serial bus triggering function can only trigger a bus at the same time. To achieve CAN and LIN bus triggering simultaneously, you can only use two oscilloscopes, and synchronizing the two oscilloscopes is also challenging.DLM2000 series oscilloscopes with dual-bus triggering function can be easily achieved by the combination of any two kinds of serial bus triggering.

After triggering to the desired serial data, engineers are still faced with the original waveform of the data. To efficiently analyze the bus, the waveform needs to be decoded. At present, the decoding technology used in digital oscilloscopes includes both software decoding and hardware decoding. Software decoding is the process of decoding the waveform data through the oscilloscope software operation to obtain the decoding results. Although it can reduce the cost of hardware, the CPU computing speed requirements are very high. In practical applications, software decoding oscilloscopes can decode for a few seconds or even more than ten seconds. Such decoding speed has lost the significance of real-time analysis, because most of the data has been lost in the waiting for decoding. A few high-end oscilloscopes use hardware decoding technology to solve this problem, making real-time decoding and analysis possible.

While displaying the decoding results, the decoding list of all captured frames can also be displayed, making it very easy to observe the correspondence between waveforms and decoding results.

To obtain correct decoding results, it is necessary to set the oscilloscope according to different bus parameters. Taking CAN bus analysis as an example, the following steps are required: specify the bus type as CAN, set the channel corresponding to the CAN signal, trigger the CAN bus by adjusting the trigger level and time axis, change the bit rate, set the invisible level, and so on. If it is an SPI bus, it is also necessary to specify the 3-wire or 4-wire system, the clock signal, and the chip select signal. This setup process requires careful attention; if any of these settings are incorrect, the decoding results may not be accurate. Particularly with the bit rate setting, even a slight error can lead to incorrect decoding results.

The complex setup process not only wastes part of the debugging time but also does not fully utilize the oscilloscope's role in improving development efficiency. DLM2000 oscilloscopes realize the automatic setting of serial bus trigger and decoding analysis. Users only need to set up the bus type and signal source channel; the system can automatically adjust the bit rate, trigger level, invisible level, and other settings, and in just two seconds, it can trigger waveforms and decode the results of synchronous display. This function makes the cumbersome serial bus setup very convenient and dramatically improves the development efficiency of engineers.

7.2 Calibration, probe selection & maintenance

(1) Oscilloscope Calibration

The purpose of calibration is to ensure that the measurement results of the oscilloscope conform to the manufacturer's specifications and national/international standards. It is divided into two categories: external calibration and internal self-calibration.

①External calibration

Performed by a certified metrology laboratory or manufacturer's service engineer using a calibrator (e.g., Fluke 5500A, 9500, etc.) that is 3-10 times more accurate than the oscilloscope under test. This is a legally valid, traceable calibration.

Periodicity: Usually once a year. The exact periodicity depends on laboratory requirements, usage environment, and frequency of use.

Procedure: The calibration engineer will: check the appearance and basic functions. Connect the high-precision calibrator to each channel of the oscilloscope. Test and adjust a series of key parameters, such as:

Vertical Amplitude Accuracy (Voltage Measurement): Input a standard voltage square wave to verify that the displayed voltage value is accurate.

Horizontal Time Base Accuracy (Time Measurement): Input a standard frequency signal to verify that the time base and measurement values are accurate.

Rise Time: Input a swift edge signal to verify the bandwidth and response of the oscilloscope.

Trigger Sensitivity: Verify if the trigger is stable and reliable under different settings.

Upon completion, a detailed calibration certificate will be issued, containing test data, uncertainty, and a passing conclusion.

② Internal self-calibration

This is an operation that can and should be performed periodically by the user themselves. It is not a traceable calibration, but utilizes a highly stable reference source inside the oscilloscope to compensate for errors due to temperature changes and circuit drift.

Periodicity: When the ambient temperature changes more than 5°C. After the first installation or after a long period of non-use. Monthly or quarterly as preventive maintenance.

How to operate:

Warm up the oscilloscope for 20-30 minutes to allow it to reach a stable operating temperature.

Disconnect all probe and input wires and leave the channel inputs open.

Find the "Self Calibration" or "Signal Path Compensation" function in the utility/maintenance menu of the oscilloscope.

Follow the on-screen instructions (usually just click "Start").

Do not touch or move the oscilloscope during the process.

Probe Compensation Calibration: This is a specific calibration for passive probes and is described in detail below.

(2) Probe Selection

Choosing the wrong probe can seriously degrade the performance of the oscilloscope and make an expensive oscilloscope pointless. The probe is part of the measurement system.

① Probe Types

Passive probe:

The most common are usually included with the oscilloscope. It consists of resistors and capacitors internally, with no active components.

Advantages: rugged, inexpensive, extensive dynamic range, no need for a power supply.

Disadvantages: low bandwidth (usually <500MHz), significant load effect.

Suitable for general-purpose low-speed measurements, including digital circuits, power supplies, and audio applications.

Active probes:

Contains active amplifier circuitry internally and requires a power supply (usually from an oscilloscope or external power supply).

Advantages: very high bandwidth (up to several GHz to tens of GHz), minimal load effect (input capacitance can be as low as below 1pF).

Disadvantages: expensive, low dynamic range, easily damaged (overvoltage).

Suitable for: high frequency signals, high speed digital signals (e.g., DDR, PCIe), low power circuits.

Differential Probes:

Measures the voltage difference between two test points, not the voltage to ground.

Advantages: floating ground measurement, strong noise immunity, safe measurement of high voltage differential signals.

Suitable for: switching power supplies, motor drives, three-phase circuits, bus signals (e.g., CAN, RS485).

Current probes:

Measures current (AC or AC/DC) by sensing the magnetic field around a wire.

Applicable: power supply, power consumption analysis, motor current, and inverter analysis.

②Select key parameters

Bandwidth: The combined bandwidth of the probe and oscilloscope is determined by the lower of the two. The selected probe bandwidth should be at least 3-5 times the highest frequency component of the signal under test.

Load effect: When the probe is connected to the circuit, it becomes a load and affects the circuit under test. The key parameters are input resistance and input capacitance. The input resistance should be as significant as possible (usually 1MΩ or 10MΩ) to minimize the load on the DC circuit. Input capacitance is a killer for high-frequency measurements. The smaller the capacitance, the less effect it will have on the edges of high-speed signals. Herein lies the advantage of active probes.

Attenuation Ratio: Commonly available are 1X, 10X, 100X, etc. A 10X probe allows for higher voltage measurements, but also attenuates the signal to 1/10th, potentially degrading the signal-to-noise ratio for small signal measurements.

Voltage range: Ensure the maximum input voltage of the probe (including both DC and AC peaks) is significantly higher than the signal under test, particularly when measuring power supplies or power circuits.

(3) Probe and Oscilloscope Maintenance

Good maintenance habits can extend the life of the equipment and ensure measurement accuracy.

① Daily use and maintenance

Mechanical protection: Avoid dropping and hitting the probe and oscilloscope. Align the slots when connecting and do not use excessive force. Do not pull, bend, or crush the probe cable. The arc should be as large as possible when winding.

Electrical protection: Never exceed the maximum input voltage. Pay particular attention to the very fragile nature of active probes. When measuring unfamiliar circuits, use the 10X attenuation mode first and start at a higher voltage level. When measuring high voltages (e.g., mains), always use high voltage differential probes and pay attention to safety regulations.

Environmental protection: Keep the probe connector and oscilloscope interface clean and dry. Avoid dust and liquid intrusion. Store in a dry, temperature-suitable environment and avoid direct sunlight.

② Probe Compensation Calibration

This is an operation that the user must check every time before using the passive probe. Incorrect compensation will result in wrong amplitude and rise time measurement.

Steps:

Connect the probe to one channel of the oscilloscope (set to 10X attenuation).

Hook the probe tip to the square wave reference output of the oscilloscope (usually a 1kHz, 5V or 2.5V square wave signal).

Using the adjustment tool that comes with the probe (usually a non-inductive screwdriver), adjust the compensation capacitor adjustment hole on the probe body.

Observe the waveform to make a perfect square wave.

Overcompensation: The waveform edges become overshoot and rounded.

Undercompensation: Waveform edges become slow and rounded.

Correctly compensated: Waveform edges are steep and flat.

Note: Each channel and each probe should be compensated separately.

8.How to choose an oscilloscope (engineer's checklist)

8.1 Key Technical Specification: Bandwidth

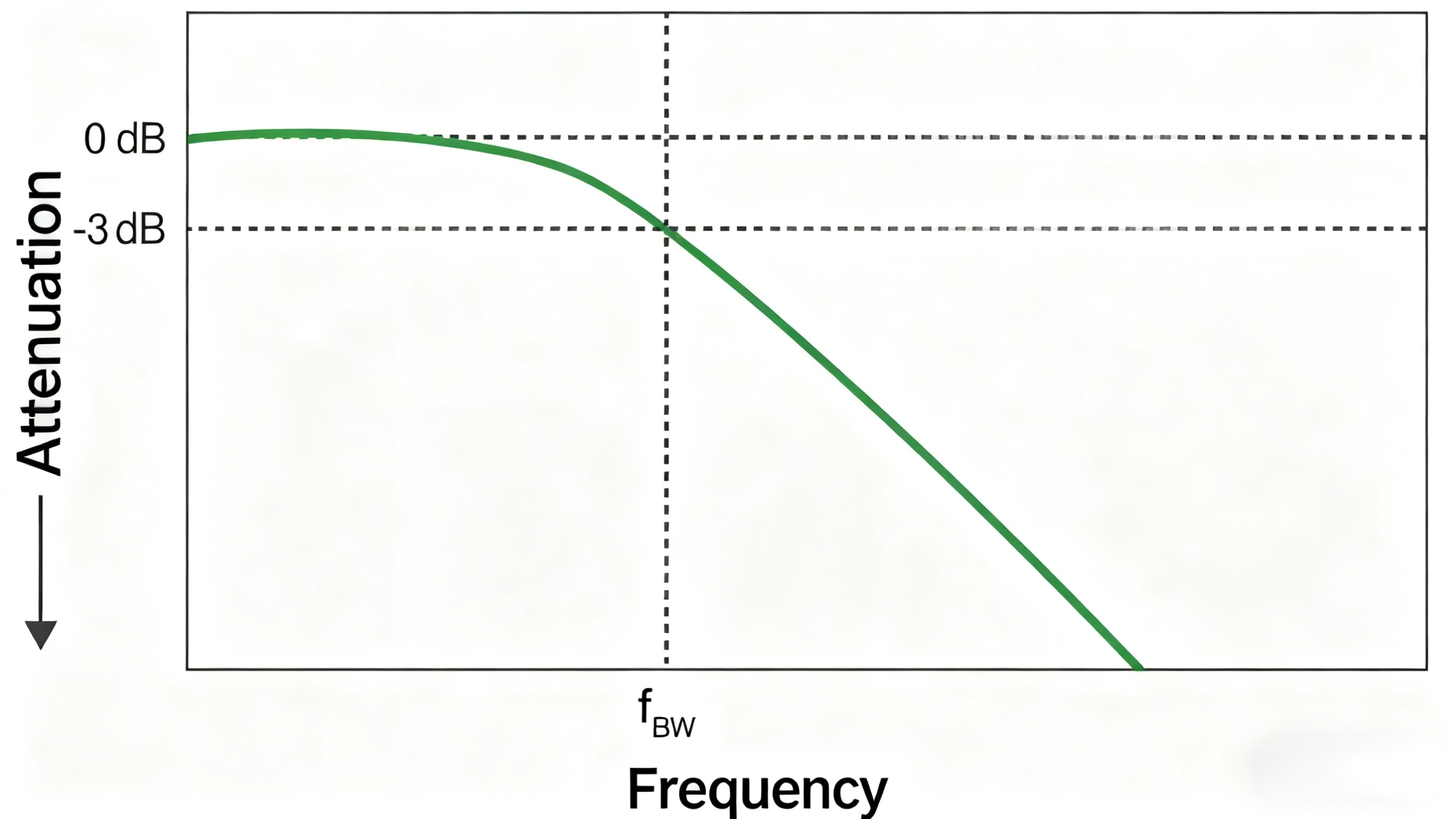

Bandwidth is the range of frequencies that an oscilloscope can measure. Oscilloscopes are one of the few broadband instruments capable of making measurements from DC (0 Hz) to their specified bandwidth. The bandwidth specification is an important consideration when purchasing an oscilloscope; if the oscilloscope does not have sufficient bandwidth, it will not be able to make accurate measurements.

The frequency response of an oscilloscope front-end amplifier is similar to that of a low-pass filter. The shape of the curve in the figure indicates that the oscilloscope is capable of measuring most of the signal components in the frequency range from DC to the 3 dB drop in signal attenuation. The oscilloscope defines the frequency corresponding to this -3 dB point as the "bandwidth" at which the voltage drops by approximately 30%.

When using an oscilloscope, you want it to capture the true rising edge of the signal accurately. The bandwidth mainly realizes this function. You can only capture a signal accurately if you have enough bandwidth. If you don't have enough bandwidth, you'll miss critical signal details and end up making flawed design assumptions.

Engineers often think that measuring a 100 MHz signal requires only 100 MHz bandwidth, but this is not the case. Our recommendation for bandwidth is to choose an oscilloscope with a bandwidth five times higher than the fastest frequency or clock rate in the device. Most oscilloscopes with bandwidths of 1 GHz and below have a Gaussian frequency response, as shown in Figure 2. This is a low-pass frequency response that decays at higher frequencies.

8.2 Sample Rate

The oscilloscope's analog-to-digital converter (ADC) is capable of converting analog signals into digital signals. This analog-to-digital conversion rate is called the "sampling rate". The manufacturer specifies the unit of sample rate as sample points/second. For example, a 300 MHz oscilloscope has a sampling rate of 2 gigasample/s. This sampling rate can also be expressed as 2 Gsample/s, 2 GaSa/s, or 2 GSp/s.

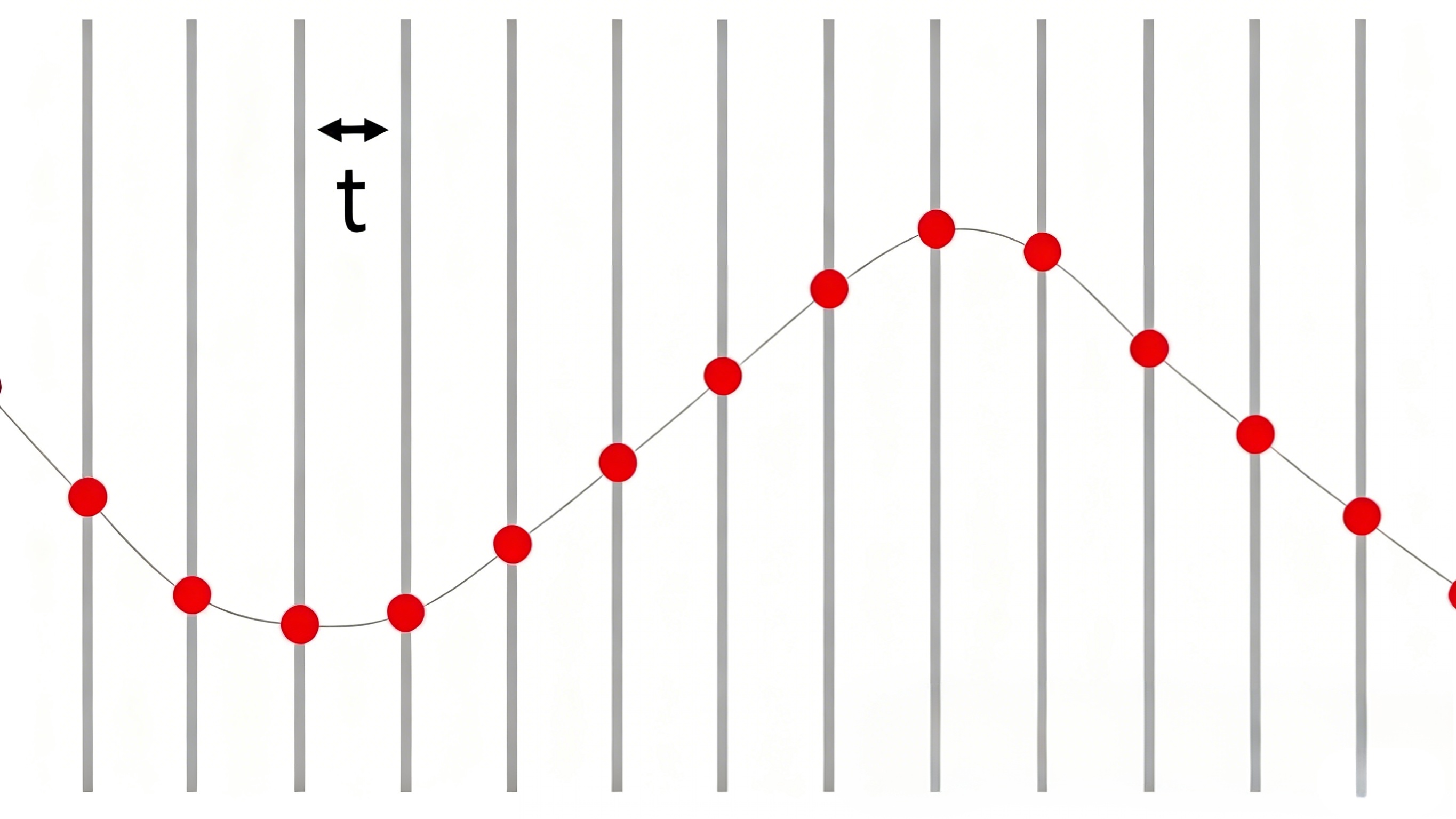

The sampling rate of the oscilloscope should be at least 2.5 times the bandwidth. For example, if the oscilloscope has a bandwidth of 1.5 GHz, the sampling rate should be higher than 3.75 Gsample/s. Most digital oscilloscopes usually meet this minimum requirement. However, oscilloscopes may interleave multiple channels to provide the maximum sampling rate.

In the case of an analog-to-digital converter (ADC), which converts an analog signal to a digital signal, it collects "samples" or data points of the analog signal, which the ADC uses to reconstruct the signal on the oscilloscope screen digitally. The rate at which these samples are collected is called the sampling rate and is measured in samples per second (Sa/s). In well-designed oscilloscopes, such as the InfiniiVision family of oscilloscopes, these samples are collected at uniform time intervals.

When you see the resulting signal on the screen, you will not know these sample points, but a smooth waveform. The oscilloscope inserts traces between each collected sample. However, if not enough samples are taken, then the interpolation does not represent the signal well, resulting in incorrect measurements.