The Quintessential Component: Ohmic Resistors, the 500 Ohm Paradigm, and the Universal Language of Color

In the vast, intricate tapestry of modern electronics, where billions of transistors dance at gigahertz speeds and signals traverse continents in milliseconds, one fundamental electronic component remains the bedrock of predictability, control, and design: the ohmic resistor. Governed by the elegant simplicity of Ohm's Law (V = I * R), these unassuming semiconductor devices embody the linear relationship between voltage, current, and electrical resistance that underpins virtually all electronic circuit design. This comprehensive exploration delves into the physics, materials, applications, and practical identification of ohmic resistors, using the ubiquitous 500 ohm resistor and its defining resistor 500 ohm color code as a central case study to illuminate their indispensable role.

Part 1: The Foundation - Ohm's Law and Ohmic Behavior

The very term "ohmic resistor" pays homage to Georg Simon Ohm, whose groundbreaking work in the 1820s established the fundamental relationship we now take for granted. His law, V = I * R, states that the constant voltage (V) across a electrical conductor is directly proportional to the electric current (I) flowing through it, with the constant of proportionality being the electrical resistance (R), measured in ohms (Ω).

The defining characteristic of an ohmic resistor is its linearity. This means:

1.Direct Proportionality: Current is directly proportional to applied voltage at a constant temperature.

2.Instantaneous Response: The electric current responds instantaneously to changes in constant voltage (within physical material limits).

3.Symmetry: Resistance is the same regardless of the direction of current flow (AC or DC).

4.Temperature Dependence: Resistance is temperature-dependent, but for a given temperature, the V-I curve is a straight line passing through the origin. The slope of this line is the resistance (R).

This linearity is not universal. Ohmic devices like diodes (semiconductor junctions), thermistors, and incandescent lamp filaments exhibit non-ohmic resistors, where the electrical resistance changes significantly with applied voltage or current. The predictability of ohmic resistors makes them irreplaceable for precise electronic circuit design and analysis.

Part 2: The Crucial Roles of Resistors in Electronic Systems

Ideal resistors function as the traffic controllers, pressure regulators, and reference setters of the electronic world. Their primary duties include:

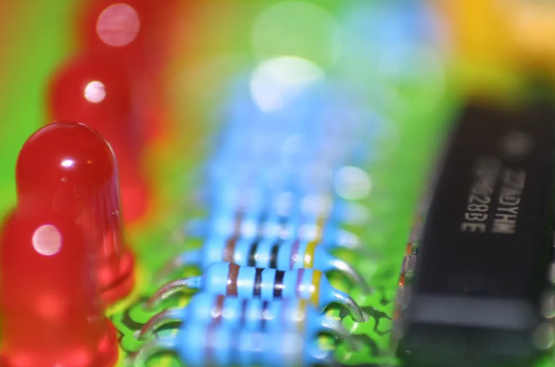

1.Current Limiting: Protecting sensitive electronic components (like LEDs, transistors, IC inputs) from excessive current increase. The types of resistor in series with an LED is the quintessential example. Without it, the low dynamic electrical resistance of the LED would cause destructive current flow.

2.Voltage Division: Creating specific, predictable voltage levels from a higher supply voltage using a simple series circuit (voltage divider). This is essential for biasing transistors, setting comparator thresholds, providing reference voltages for Analog-to-Digital Converters (ADCs), and scaling sensor outputs.

3.Biasing Active Devices: Establishing the correct DC operating point (quiescent point) for transistors and operational amplifiers, ensuring they function linearly within their intended range for amplification or switching.

4.Impedance Matching & Termination: Preventing signal reflections in transmission lines (e.g., coaxial cables, PCB traces) by matching the source and load impedances, crucial for signal integrity in high-speed digital and RF electric circuits.

5.Pull-up and Pull-down Resistors: Ensuring digital logic inputs settle to a defined state (HIGH via pull-up to Vcc, LOW via pull-down to GND) when not actively driven, preventing floating inputs that cause erratic behavior and high power consumption in CMOS circuit diagram.

6.Gain Setting: Determining the amplification factor in operational amplifier configurations (e.g., inverting/non-inverting amps) and feedback networks.

7.Current Sensing: Converting current flow into a measurable voltage drop (V = I * R) for monitoring or control purposes (often using low-value "shunt" resistors).

8.Filter Networks: Working in conjunction with capacitors (RC circuit diagram) and inductors (RL, RLC circuit diagram) to create low-pass, high-pass, band-pass, and band-stop filters for signal conditioning.

9.Heating Elements: Intentionally dissipating electrical thermal energy as heat in applications like defrosters, heaters, and resistive loads (though specialized high-power resistors are typically used).

Part 3: The 500 Ohm Resistor - A Versatile Workhorse

While ideal resistors span an enormous range (milliohms to gigaohms), the 500 ohm resistor occupies a highly practical and frequently encountered "sweet spot" in electronic design. Its value strikes an effective balance between current limitation, voltage drop, power dissipation, and signal level management in numerous common scenarios:

● LED Driving: A cornerstone application. Consider a standard red LED (forward voltage Vf ≈ 1.8-2.2V) powered from a 5V supply. To achieve a target current (If) of 10mA:

R = (Vsupply - Vf) / If = (5V - 2V) / 0.01A = 300ΩWhile 300Ω is ideal, a 500 ohm resistor is a very common choice, providing a safe, slightly lower current (~6mA using Vf=2V: (5-2)/500 = 0.006A). This conserves power slightly while ensuring longevity and sufficient brightness for many indicators. For higher voltage supplies (e.g., 12V), multiple LEDs in series or higher resistor values are used, but 500Ω remains relevant in parallel branches or lower-current indicators.

● Sensor Biasing & Voltage Dividers: Many resistive sensors (photoresistors/LDRs, thermistors, flex sensors, potentiometers) are used in voltage divider configurations. A 500 ohm resistor paired with the sensor provides a good compromise:

Current: Enough current to generate a measurable voltage drop across the sensor without excessive power drain (important for battery-powered devices).

Range: Provides a useful output voltage range centered within typical supply voltages (e.g., 0-5V) for many common sensor resistances (hundreds of ohms to tens of kilo-ohms).

Linearity: Helps mitigate the inherent non-linearity of some sensors like thermistors when used in simple dividers.

● Digital Pull-up/Pull-down: While higher values (e.g., 10kΩ) are common for minimizing current draw on CMOS inputs, 500 ohm resistors are sometimes used in specific scenarios:

Stronger Pulling: Where faster signal rise times or immunity to significant leakage currents are needed.

I²C Bus Pull-ups: On shorter bus runs or with faster clock speeds, lower pull-up values (like 500Ω - 2kΩ) can improve signal integrity by reducing RC time constants, though power consumption increases.

● Audio Signal Attenuation & Impedance Matching: In line-level audio circuit elements (e.g., mixing desks, effects pedals), 500 ohm resistors can be found in pad circuit board (attenuators) or as part of impedance matching networks, particularly where bridging inputs or driving specific cable types are involved.

● Operational Amplifier Circuits: Can serve as gain-setting resistors (Rf or Rin) for moderate gains, as part of summing networks, or in integrator/differentiator time constants (with capacitors) for specific frequency ranges.

● Transistor Biasing: Useful in base current limiting ideal resistors or as part of voltage divider networks establishing base bias for small-signal transistors.

● Test & Measurement: Frequently used as known loads, calibration references, or in decade boxes due to its manageable value.

The 500Ω value exemplifies versatility: high enough for effective current limitation without causing excessive voltage sag, yet low enough to provide adequate signal levels and avoid susceptibility to noise pickup in many contexts. While the E24/E96 standard preferred values list 470Ω and 510Ω as the closest common values, explicitly labeled 500 ohm resistors are readily available and used where that specific value is optimal.

Part 4: Speaking in Color - The Resistor 500 Ohm Color Code

The small size of axial lead variable resistors necessitates a universal, color-based identification system. The single resistor color code is a brilliant, standardized solution. For a standard 4-band resistor (the most common for general-purpose ±5% or ±1% tolerance parts), decoding the resistor 500 ohm color code is straightforward:

1.Band 1 (First Significant Digit): Represents the first digit of the internal resistance value. For 500, the first digit is 5. The base color for 5 is Green.

2.Band 2 (Second Significant Digit): Represents the second digit. For 500, the second digit is 0. The base color for 0 is Black.

3.Band 3 (Multiplier): Represents the power of ten (10^N) by which the first two digits are multiplied. 500 ohms is 5 * 10^2 (since 5 * 100 = 500). The multiplier for 10^2 (100) is Brown.

4.Band 4 (Tolerance): Represents the allowable manufacturing variation. For a typical general-purpose resistor, this is often ±5%, represented by Gold.

Therefore, the definitive 4-band resistor 500 ohm color code is: Green - Black - Brown - Gold.

● Practical Considerations:

Standard Values: As noted, 500Ω isn't a primary E24 value. 470Ω (Yellow-Violet-Brown-Gold) and 510Ω (Green-Brown-Brown-Gold) are far more common off-the-shelf. A electronic component specifically manufactured and labeled as 500Ω will use Green-Black-Brown-Gold.

Reading Direction: Identify the tolerance band (Gold/Silver) first, usually slightly spaced or thicker, to orient the resistor correctly.

5-Band & 6-Band Codes: Higher precision resistors (e.g., ±1%, ±0.5%) use a 5-band code (3 significant digits). For 500Ω: Green-Black-Black-Black-[Tolerance]. 6-band resistors add a temperature coefficient band (e.g., Brown for 100 ppm/°C).

SMD Codes: Surface Mount Device (SMD) resistors use numerical codes. A 500Ω chip resistor is typically marked "500" (EIA-96 code uses "01C" for 499Ω, but "500" is common for exact values).

Part 5: Beyond the Ideal - Tolerance, Power, and Non-Ohmic Realities

While the core principle is linearity, real-world ohmic resistors exhibit important secondary characteristics:

● Tolerance: The Gold band (±5%) signifies the permissible deviation from the nominal 500Ω value. A practical resistor could measure anywhere between 475Ω and 525Ω. Precision applications demand tighter tolerances (e.g., ±1% Brown, ±0.1% Violet). Tolerance arises from manufacturing variations in materials and dimensions.

● Power Rating (Wattage): The maximum power (P = I² * R = V² / R) the resistor can continuously dissipate as heat without damage or significant parameter shift. Common axial ratings include 1/8W (0.125W), 1/4W (0.25W), 1/2W (0.5W), and 1W. Exceeding this rating causes overheating, potentially leading to internal resistance drift, open-circuit failure, or even fire. For a 500 ohm resistor:

At 1/4W rating: Max Current I = sqrt(P/R) = sqrt(0.25/500) ≈ 0.0224A (22.4mA), Max Voltage V = sqrt(P*R) = sqrt(0.25*500) ≈ 11.18V.

Derating: Power rating decreases significantly with increasing ambient temperature. Manufacturers provide derating curves.

● Temperature Coefficient of Resistance (TCR): Expressed in ppm/°C (parts per million per degree Celsius), TCR quantifies how much the constant resistance changes with temperature increase. Most common metal film resistors have TCRs around ±50 to ±100 ppm/°C. A 500Ω resistor with a TCR of +100 ppm/°C will increase by 0.5Ω for every 10°C rise in temperature (ΔR = R * TCR * ΔT = 500 * 0.0001 * 10 = 0.5Ω). Precision resistors have TCRs as low as ±5 ppm/°C.

● Voltage Coefficient: At extremely high voltages (approaching the practical resistor's maximum working voltage), the discrete resistance might deviate slightly from its nominal value due to effects like electron emission or resistive material stress. This is usually negligible for standard applications.

● Frequency Effects: At very high frequencies (MHz to GHz range), parasitic capacitance (between leads/windings) and inductance (from the resistive element's path) become significant. The single resistor behaves less like a pure resistance and more like a complex impedance (R + jX). This limits usable frequency range, especially for wirewound types which have high inductance. Film resistors are preferred for RF.

● Noise: All resistors generate inherent thermal noise (Johnson-Nyquist noise), proportional to resistance, bandwidth, and absolute temperature (V_n = sqrt(4kTRB)). Carbon composition resistors also exhibit significant current noise (excess noise), making metal film the preferred choice for low-noise preamplifiers and sensitive analog circuit board.

Part 6: Materials and Construction - From Carbon to Ceramic

The performance characteristics of a resistor are heavily influenced by its construction and resistive materials:

1.Carbon Composition (CC): An older technology consisting of carbon granules mixed with a binder. Advantages: Good surge handling. Disadvantages: Poor tolerance (±5% typical), high noise, significant negative TCR, poor stability over time and temperature. Rarely used today.

2.Carbon Film (CF): A carbon layer deposited on a ceramic rod. Advantages: Better tolerance (±2%, ±5%), lower noise and better stability than CC, low cost. Disadvantages: Still moderate TCR (-200 to -800 ppm/°C), can be somewhat noisy for sensitive circuit element. Common in general-purpose applications.

3.Metal Film (MF): A thin layer of metal alloy (typically NiCr or TaN) deposited on a ceramic substrate. Advantages: Excellent tolerance (±1%, ±0.1%, ±0.5%), low TCR (±15 to ±100 ppm/°C), very low noise, excellent long-term stability. This is the dominant technology for precision and general-purpose axial resistors. A typical 500 ohm resistor for most applications would be metal film.

4.Metal Oxide Film (MOF): Similar to metal film but uses a metal oxide (like tin oxide). Advantages: Good tolerance (±1%, ±2%), high power density, good surge handling, excellent stability at high temperatures, low noise. Disadvantages: Slightly higher TCR than MF. Widely used in power supplies and surge protection.

5.Wirewound (WW): Resistance wire (e.g., Nichrome, Manganin, Kanthal) wound around a ceramic or fiberglass core. Advantages: Very low TCR (±10 ppm/°C achievable), high precision, excellent stability, very high power ratings (watts to kilowatts). Disadvantages: Significant inductance makes them unsuitable for high frequencies, larger size, higher cost. Used for precision measurement shunts, power loads, and high-power applications. A 500Ω wirewound would be bulky and inductive.

6.Foil Resistors: A thin metal alloy foil bonded to a ceramic substrate. Advantages: Ultra-low TCR (±1 ppm/°C), highest precision and stability. Disadvantages: High cost. Used in metrology and critical instrumentation.

7.Surface Mount Device (SMD) Chip Resistors: The backbone of modern electronics. Ceramic substrate with thick or thin film resistive element (similar to MF/MOF) and metal end terminations. Advantages: Tiny size, low inductance, suitability for automated assembly, wide range of values and tolerances. Marked with laser-etched numerical codes (e.g., "500" for 500Ω, "511" for 510Ω). Power ratings range from 1/16W to 1W+ in standard sizes (0201, 0402, 0603, 0805, 1206).

Part 7: Standards, Specifications, and Selection

Designing with resistors requires careful consideration of specifications beyond just the constant resistance value (like the 500 ohm resistor) and its color code:

● International Standards: Color codes are defined in standards like IEC 60062. Resistor characteristics (power rating, temperature range, test methods) are covered by standards like MIL-STD-202 (military), IEC 60115 (generic), and various JIS standards.

● Key Parameters:

Resistance Value & Tolerance: Nominal value and allowable variation.

Power Rating: Maximum continuous power dissipation at specified ambient temperature.

Maximum Working Voltage: Highest voltage allowed across terminals (distinct from power rating).

Maximum Overload Voltage: Short-duration surge voltage rating.

Temperature Coefficient of Resistance (TCR): Change in constant resistance per degree Celsius.

Dielectric Withstanding Voltage (Isolation): Voltage withstand capability between resistor body and external elements (for insulated types).

Noise: Thermal and excess (current) noise figures.

Stability: Long-term drift under load and environmental stress.

Operating Temperature Range: Ambient temperatures within which specifications are guaranteed.

● Selection Criteria: Choosing the right resistor involves balancing value, tolerance, power rating, TCR, noise, size, cost, and suitability for the frequency range and environmental conditions. A 500 ohm resistor for an LED indicator might be a cheap carbon film 1/4W part. The same value used in a precision voltage reference circuit would demand a metal film resistor with ±0.1% tolerance and low TCR.

Conclusion: The Enduring Pillar of Electronics

The ohmic resistor, defined by its faithful adherence to V = I * R, is far more than just a simple electronic component. It is a fundamental enabler of electronic design, providing control, predictability, and reference points upon which complex systems are built. From the simplest battery-powered gadget to the most sophisticated supercomputer, resistors are omnipresent, performing critical tasks silently and reliably.

The 500 ohm resistor exemplifies this perfectly. Its value embodies a practical compromise found in countless applications – limiting LED current without excessive power loss, biasing sensors effectively, pulling signals firmly, and dividing voltages precisely. Mastering its identification through the universal resistor 500 ohm color code (Green-Black-Brown-Gold) unlocks the ability to interpret the values of millions of similar electronic components populating circuit boards globally. This color code is a testament to the elegant simplicity and standardization that underpins the entire electric field.

Understanding the nuances – tolerance, power dissipation, temperature effects, material choices (from carbon film to precision metal foil), and the potential differences between axial, SMD, and specialized types – is crucial for effective electrical circuit design, troubleshooting, and innovation. As electronics continue to evolve, pushing into quantum realms and unprecedented speeds, the fundamental principles embodied by the ohmic resistor and Ohm's Law remain an unshakeable foundation. The humble resistor, particularly versatile values like 500 ohms, will continue to be an indispensable workhorse, shaping the flow of electrons and the trajectory of technology for generations to come. It is a profound reminder that deep understanding of fundamental electronic components is the bedrock of true electrical engineering mastery.