How to Choose the Right Integrated Circuits Supplier

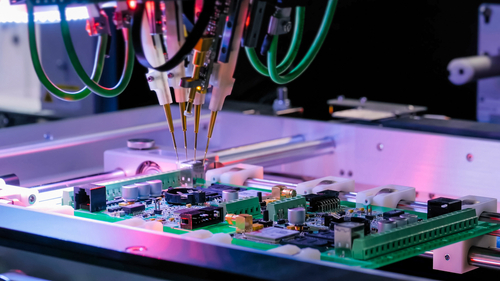

In today's technology-driven world, integrated circuits (ICs) have become the backbone of modern electronics. From smartphones to industrial automation, nearly every device relies on IC electronic components to function efficiently. Selecting the right integrated circuits supplier is, therefore, a critical decision that can significantly impact the performance, reliability, and cost-effectiveness of your products.With so many integrated circuits suppliers in the global market, it can be challenging to choose the one that best meets your specific needs. In this blog, we will explore key factors to consider when selecting an IC supplier, dive into the importance of IC electronic components in modern electronics, and provide actionable insights to guide your decision. We will also feature trusted suppliers like unikeyic Electronics and offer a comprehensive FAQ section to address common questions about integrated circuit suppliers and IC electronic components.

Why Choosing the Right Integrated Circuits Supplier Matters

Integrated circuits (ICs) play a pivotal role in nearly all electronic devices, from simple gadgets to complex computing systems. They integrate multiple electronic functions into a single chip, allowing for smaller, faster, and more efficient devices. The quality, availability, and cost of ICs can directly influence the development and performance of your electronic products. As such, choosing the right supplier is critical to ensuring that your devices meet the highest standards of performance and reliability.

Here are some key areas where the choice of an IC supplier can have a profound impact:Product Performance: The quality of IC electronic components directly affects the functionality and reliability of your products.Cost Efficiency: A well-established supplier can help you control costs by offering competitive pricing and stable supply chains.Time to Market: Delays in the delivery of ICs can stall production schedules and product launches, impacting revenue and market share.Supply Chain Security: Working with reliable suppliers can reduce the risk of supply chain disruptions, particularly during global shortages or crises.

Let’s explore the critical factors you should consider when selecting the best integrated circuits supplier for your business.

Key Factors to Consider When Choosing an Integrated Circuits Supplier

1. Technical CapabilitiesOne of the first things to evaluate in an integrated circuits supplier is their technical capabilities. Suppliers must have a deep understanding of the latest technologies in the IC industry and be able to design and deliver high-quality IC electronic components that meet the evolving demands of the market.A supplier with robust technical expertise should be able to:Provide reliable, state-of-the-art ICs that meet the performance requirements of your devices.Offer insights into new technological trends, such as AI-based chips, low-power ICs, and advanced packaging techniques.Develop customized solutions tailored to your specific needs, including designing, prototyping, and testing new IC designs.When choosing a supplier, assess whether they have the engineering resources and expertise to support your technology roadmap, now and in the future.

2. Experience and Reputation

An experienced and reputable supplier can significantly reduce the risks associated with procurement. Look for suppliers with a solid track record of working with established clients across various industries.

Factors to consider:Years of Experience: A supplier with a long history in the industry is more likely to have the experience and knowledge necessary to handle complex orders, anticipate potential issues, and offer solutions that enhance the reliability of your products.Reputation: Research the supplier’s reputation in the market. Are they known for delivering high-quality products on time? Do they offer strong customer service and after-sales support? Reading customer reviews and testimonials can provide valuable insights into a supplier's reputation.Suppliers like Unikeyic Electronics, for example, have built a reputation for reliability and quality in the IC component market. By partnering with experienced suppliers, you can benefit from their deep industry knowledge and expertise.

3. Cost-EffectivenessWhile quality and technical capabilities are crucial, cost is also a major factor when selecting an IC supplier. You need to ensure that the pricing of the components aligns with your budget and offers good value for money without compromising on performance or reliability.Consider the following when evaluating cost-effectiveness:Competitive Pricing: Compare pricing among different suppliers to ensure that you're getting a fair deal. However, be cautious of suppliers offering prices that are too low, as this could be an indicator of poor-quality components.Total Cost of Ownership: Look beyond the initial purchase price and consider the total cost of ownership, which includes factors like shipping costs, customs fees, lead times, and the potential cost of delays or faulty components.Long-Term Contracts: Some suppliers offer discounted pricing for long-term contracts or bulk purchases. This can help you secure a stable supply at lower prices, making your production process more cost-efficient.

4. Customer Support and ServiceStrong customer support is essential when working with IC suppliers, especially during the design, production, and testing stages of your product development. A responsive and knowledgeable supplier can quickly address any issues, provide technical assistance, and ensure smooth communication throughout the procurement process.Look for suppliers who offer:Dedicated Account Managers: Suppliers who provide dedicated support staff can offer personalized service and quicker responses to your inquiries.Design and Engineering Support: Some suppliers offer design consultation services to help you select the right IC electronic components for your specific applications. This is particularly valuable for companies that require specialized ICs or are developing cutting-edge products.Technical Troubleshooting: A reliable supplier should offer post-sale support, helping you troubleshoot any issues that arise during production or testing.Unikeyic Electronics, for instance, is known for providing exceptional customer support, including engineering services and real-time assistance to help clients optimize their product designs.

5. Innovation and FlexibilityThe electronics industry is constantly evolving, with new technologies and design requirements emerging regularly. Suppliers who demonstrate innovation and flexibility are more likely to stay ahead of the curve and offer cutting-edge solutions that keep your products competitive.Consider the following when assessing a supplier's ability to innovate:Adaptability: Can the supplier quickly respond to changes in technology or market conditions? Are they able to offer custom IC designs that meet the unique needs of your business?Research and Development: Look for suppliers who invest in R&D and have a pipeline of innovative products. This can ensure that you have access to the latest technologies and can stay competitive in the market.Innovative suppliers can also provide flexible solutions tailored to your specific requirements, whether you need custom ICs, new packaging designs, or enhanced functionality.

6. Lead Times and Delivery ReliabilityTimely delivery of IC components is essential for keeping your production line running smoothly and avoiding costly delays. When choosing an IC supplier, consider their track record for on-time delivery and their ability to meet your lead time requirements.Key factors to consider:Manufacturing Capacity: Does the supplier have the capacity to meet your order volumes and deadlines? Make sure they have adequate resources to scale production according to your needs.Supply Chain Management: Evaluate the supplier's supply chain infrastructure. Do they have a robust logistics network that can handle both domestic and international shipments? How do they manage disruptions, such as material shortages or shipping delays?Inventory Management: Some suppliers offer inventory management services, allowing you to maintain a buffer stock of critical components. This can help mitigate the impact of supply chain disruptions and ensure continuity in your production process.Suppliers like Unikeyic Electronics have earned a reputation for reliable delivery and efficient supply chain management, ensuring that clients receive their components on time and within budget.

7. Diversification of SuppliersRelying on a single IC supplier can be risky, particularly in times of global component shortages or unexpected disruptions. To mitigate these risks, it’s advisable to work with a diversified network of suppliers.Having multiple suppliers allows you to:Reduce Supply Chain Risk: If one supplier is unable to deliver components on time, you can rely on alternative suppliers to fill the gap.Leverage Competitive Pricing: By working with multiple suppliers, you can compare pricing and negotiate better terms for your purchases.

Enhance Supply Chain Flexibility: A diversified supplier base gives you more flexibility to respond to market changes, such as fluctuations in demand or supply chain disruptions.

Recommended Supplier: Unikeyic Electronics

When it comes to sourcing high-quality IC electronic components, Unikeyic Electronics stands out as a trusted partner. With a strong track record in the industry, Unikeyic Electronics offers a wide range of ICs and electronic components that meet the needs of various applications, from consumer electronics to industrial automation.

Unikeyic Electronics is known for:Exceptional Quality: They offer ICs from reputable manufacturers, ensuring that you receive components that meet the highest standards of performance and reliability.Customer-Centric Service: Their team of experts provides personalized support and technical assistance throughout the procurement process.Competitive Pricing: Unikeyic Electronics offers competitive pricing and flexible terms, making them an ideal choice for businesses looking to balance cost and quality.

With Unikeyic Electronics, you can trust that your IC sourcing needs will be met with professionalism, quality, and efficiency.

IC Electronic Components and Integrated Circuits Suppliers FAQ

1. What are the key factors to consider when selecting an IC supplier?Key factors include the supplier's technical capabilities, experience, reputation, cost-effectiveness, customer support, innovation, delivery reliability, and supply chain management.

2. How do I ensure the quality of IC electronic components?Work with reputable suppliers who have a proven track record of delivering high-quality components. Request samples for testing, check for certifications, and read customer reviews.

3. How can I mitigate the risks of supply chain disruptions?Diversify your supplier base to avoid over-reliance on a single supplier. Maintain buffer stock of critical components and work with suppliers who offer inventory management services.

4. What is the role of customer support in IC procurement?Customer support is crucial for addressing technical issues, troubleshooting problems, and ensuring smooth communication throughout the procurement process. Strong customer support can help you avoid delays and improve overall efficiency.

5. Why is it important to choose a supplier with innovation and flexibility?The electronics industry evolves rapidly, and suppliers who demonstrate innovation and flexibility can offer cutting-edge solutions that keep your products competitive. They are also better equipped to adapt to changes in technology and market conditions.

By considering these factors and working with reliable suppliers like Unikeyic Electronics, you can ensure that your integrated circuits and electronic components meet the highest standards of quality, performance, and reliability.