Solder & Flux

Results:Solder & Flux Results:

Comprehensive

Price Priority

Stock Priority

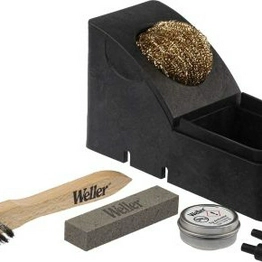

Image

Part Number

Manufacturer

Description

Availability

Unit Price

Quantity

Operation

1+ $84.2359

5+ $80.0192

15+ $76.0232

50+ $72.2233

150+ $68.6072

-

+

Ext. Price: $168.47

MOQ: 2

Mult: 1

SPQ: 1

1+ $410.638

-

+

Ext. Price: $410.63

MOQ: 1

Mult: 1

SPQ: 1

1+ $236.7391

-

+

Ext. Price: $236.73

MOQ: 1

Mult: 1

1+ $86.581

5+ $76.8285

10+ $74.172

25+ $69.951

50+ $68.208

-

+

Ext. Price: $86.58

MOQ: 1

Mult: 1

SPQ: 1

Weller

WellerWilo Desoldering gun tip, DX 115series, T0051314599, 0.7mmnozzle, used forCV-5200 system、CV-H5-DS hand piece、MX-500、MX-5000、MX-5200、MX-DS1

Quantity: 11

Ship Date: 7-15 working days

5+ $12.0004

10+ $11.3998

-

+

Ext. Price: $96.00

MOQ: 8

Mult: 1

SPQ: 1

PACE Worldwide

HEATER ASSEMBLY, SX90 (BLUE); Output Power:-; For Use With:Pace SX-90 and SX-100 Handpiece; Length:-; Product Range:-; SVHC:No SVHC (15-Jan-2019); Accessory Type:Heating Element

Quantity: 24

Ship Date: 6-14 working days

1+ $164.9873

5+ $161.7522

-

+

Ext. Price: $164.98

MOQ: 1

Mult: 1

CHIP QUIK

SOLDER BAR SN96.5/AG3.5 1LB (454

Quantity: 39

Ship Date: 7-12 working days

1+ $91.7904

5+ $79.0962

10+ $74.1718

25+ $68.1163

50+ $63.8525

100+ $59.8418

-

+

Ext. Price: $91.79

MOQ: 1

Mult: 1

SPQ: 1

Weller

Weller, Applicable toDS21; DS22; DS80; DSX80 Soldering Irons

Quantity: 4

Ship Date: 7-13 working days

1+ $62.3592

-

+

Ext. Price: $62.35

MOQ: 1

Mult: 1

1+ $56.9377

5+ $53.5178

15+ $51.4707

50+ $49.1908

150+ $47.156

-

+

Ext. Price: $113.87

MOQ: 2

Mult: 1

SPQ: 1

1+ $104.2829

5+ $80.4607

-

+

Ext. Price: $104.28

MOQ: 1

Mult: 1

Weller

Weller Welding accessories, WSRseries, used forWTMT

Quantity: 8

Ship Date: 7-13 working days

1+ $146.7222

-

+

Ext. Price: $146.72

MOQ: 1

Mult: 1

1+ $1635.5951

-

+

Ext. Price: $1635.59

MOQ: 1

Mult: 1

5+ $20.2164

10+ $19.8572

-

+

Ext. Price: $101.08

MOQ: 5

Mult: 1

SPQ: 1

1+ $81.4902

5+ $76.6116

15+ $73.6697

50+ $70.4091

150+ $67.4795

-

+

Ext. Price: $162.98

MOQ: 2

Mult: 1

SPQ: 1

1+ $15.2733

10+ $14.5133

50+ $13.7901

150+ $13.0914

500+ $12.4417

-

+

Ext. Price: $91.63

MOQ: 6

Mult: 1

SPQ: 1

Weller

Weller Welding accessories, for general purpose

Quantity: 2

Ship Date: 7-13 working days

1+ $98.9466

-

+

Ext. Price: $98.94

MOQ: 1

Mult: 1

1+ $10.1289

-

+

Ext. Price: $101.28

MOQ: 10

Mult: 1

SPQ: 1

1+ $16.8668

10+ $16.021

50+ $15.2243

150+ $14.4643

500+ $13.7411

-

+

Ext. Price: $101.20

MOQ: 6

Mult: 1

SPQ: 1

5+ $4.7806

-

+

Ext. Price: $95.61

MOQ: 20

Mult: 1

SPQ: 1

1+ $32.042

-

+

Ext. Price: $96.12

MOQ: 3

Mult: 1

SPQ: 1