Solder & Flux

Results:Solder & Flux Results:

Comprehensive

Price Priority

Stock Priority

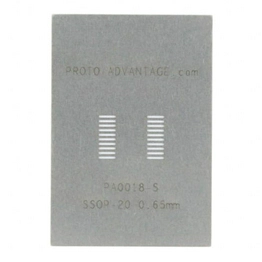

Image

Part Number

Manufacturer

Description

Availability

Unit Price

Quantity

Operation

Apex Tool

WTP 90 SOLDERING IRON 9

Quantity: 7

Ship Date: 5-12 working days

Within 1 year

1+ $359.1108

3+ $345.7335

5+ $344.001

-

+

Ext. Price: $359.11

MOQ: 1

Mult: 1

1+ $68.58

-

+

Ext. Price: $68.58

MOQ: 1

Mult: 1

SPQ: 1

1+ $94.4784

-

+

Ext. Price: $94.47

MOQ: 1

Mult: 1

SPQ: 1

1+ $27.27

-

+

Ext. Price: $27.27

MOQ: 1

Mult: 1

SPQ: 1

1+ $547.3125

-

+

Ext. Price: $547.31

MOQ: 1

Mult: 1

SPQ: 1

1+ $26.962

-

+

Ext. Price: $26.96

MOQ: 1

Mult: 1

SPQ: 1

1+ $21.84

-

+

Ext. Price: $21.84

MOQ: 1

Mult: 1

SPQ: 1

1+ $13.1905

5+ $12.353

10+ $11.6316

25+ $9.9036

50+ $8.6625

100+ $8.4735

-

+

Ext. Price: $13.19

MOQ: 1

Mult: 1

SPQ: 1

1+ $9.062

-

+

Ext. Price: $9.06

MOQ: 1

Mult: 1

SPQ: 1

1+ $71.5

-

+

Ext. Price: $71.50

MOQ: 1

Mult: 1

SPQ: 1

1+ $21.125

-

+

Ext. Price: $21.12

MOQ: 1

Mult: 1

SPQ: 1

1+ $32.4

-

+

Ext. Price: $32.40

MOQ: 1

Mult: 1

SPQ: 1

1+ $7.0495

-

+

Ext. Price: $7.04

MOQ: 1

Mult: 1

SPQ: 1

1+ $28.38

-

+

Ext. Price: $28.38

MOQ: 1

Mult: 1

SPQ: 1

1+ $103.95

-

+

Ext. Price: $103.95

MOQ: 1

Mult: 1

SPQ: 1

1+ $21.84

-

+

Ext. Price: $21.84

MOQ: 1

Mult: 1

SPQ: 1

1+ $22.087

-

+

Ext. Price: $22.08

MOQ: 1

Mult: 1

SPQ: 1