Button Cell Sizes, Chemistries, and Cross-Reference Standards: The Definitive Guide

Understanding Button Cells: Definition and Core Principles

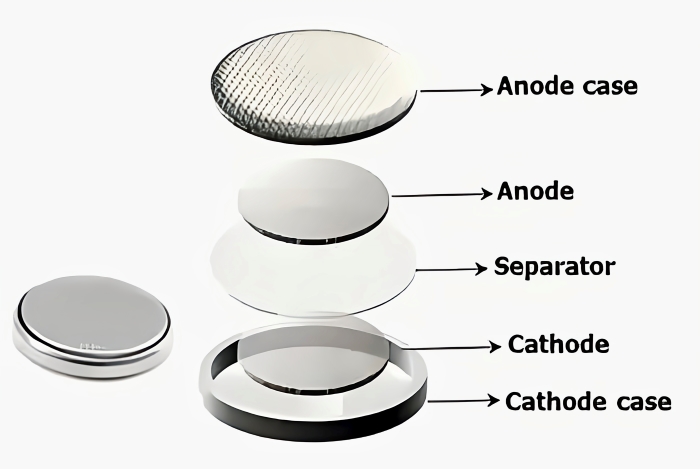

Button cells, also known as coin cells, are compact, flat, and typically single-cell power sources characterized by their small size and circular shape. These button batteries (or Button Cell Battery) are broadly categorized into two main types: disposable button batteries and rechargeable button batteries. When selecting button or coin-shaped batteries, beyond ensuring physical battery size compatibility, several key electrical characteristics warrant close attention: nominal voltage (commonly 1.5V and 3V), Nominal Capacity (measured in milliampere-hours, mAh, representing the charge reserve or energy capacity), discharge curve (affecting voltage stability), internal resistance, and temperature tolerance. These factors directly determine the battery's performance and suitability for specific electronic devices.

Mastering Button Cell Naming Conventions and Sizing Standards

In various small electronic devices, the compatibility of button batteries directly depends on their naming and dimensions. However, manufacturer-specific codes can often complicate the selection process. Therefore, systematically understanding naming conventions and Battery Cross Reference Chart logic is crucial.

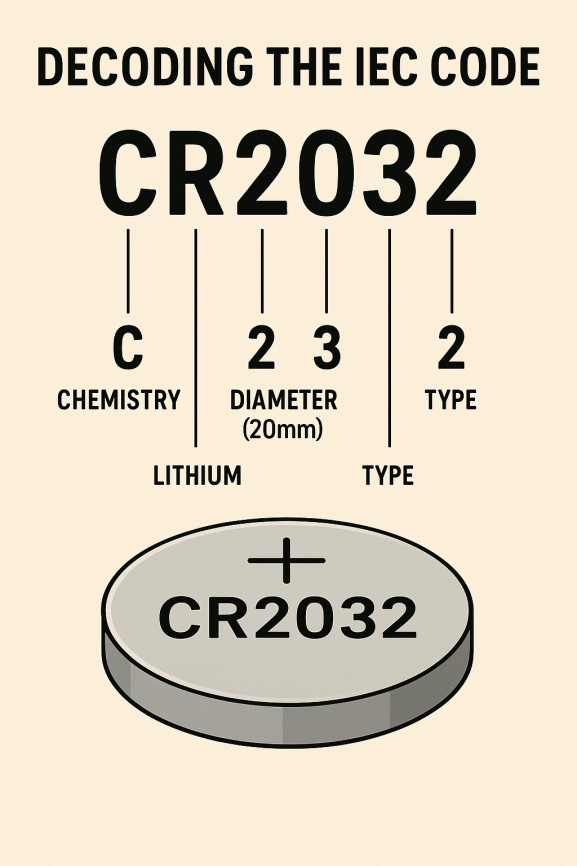

The IEC 60086-3 Standard: The Rosetta Stone of Button Cell Naming

To decipher battery code logic, one must first anchor to the IEC 60086-3 standard—the industry's universally recognized "Rosetta Stone ”. As manufacturers develop proprietary codes to align with their product lines, naming inconsistencies often arise in the market. The IEC 60086-3 standard, as the sole standardized system, provides a unified naming language for global coin Cell Batteries. The coding structure under this standard is clear and explicit. Taking the typical CR2032 (a Lithium Manganese Dioxide button battery) as an example, it consists of two parts: a chemical prefix and a size code. The chemical prefix directly reveals the battery's chemistry: C represents Lithium Manganese Dioxide (or lithium manganese dioxide batteries), L represents alkaline batteries (e.g., LR button battery), S represents silver oxide (or silver oxide button batteries, e.g., SR button battery), P represents zinc-air button batteries (or Zinc air button battery), while R consistently indicates a round (or circular) form factor (the R in CR, LR, SR etc. is often omitted in the general chemical prefix discussion but is implicit in the "R"ound cell designation of the full code). The subsequent four-digit size code contains critical parameters: the first two digits denote the diameter (in millimeters), while the last two represent the thickness (in tenths of a millimeter). For CR2032, this signifies a circular lithium battery with a diameter of 20 mm and a thickness of 3.2 mm.

Essential Button Cell Size Chart: IEC Cross-Section

Below are the dimensional variations for 20 common Button Battery Sizes under IEC standards.

|

IEC Size Code |

Nominal Diameter (mm) |

Nominal Thickness (mm) |

Common Tolerances |

Corresponding Non-IEC Code |

|

SR626SW |

6.8 |

2.6 |

Diameter ±0.2mm, Thickness ±0.15mm |

377, AG4, LR626, SR626 |

|

SR44SW |

11.6 |

5.4 |

Diameter ±0.2mm, Thickness ±0.2mm |

303, AG13, LR44, 357 |

|

SR44W |

11.6 |

5.4 |

Diameter ±0.2mm, Thickness ±0.2mm |

357, SR44, AG13, A76 |

|

SR920SW |

9.5 |

2.0 |

Diameter ±0.2mm, Thickness ±0.15mm |

371, AG6, LR920, SR920 |

|

SR621SW |

6.8 |

2.1 |

Diameter ±0.2mm, Thickness ±0.15mm |

364, AG1, LR621, SR621 |

|

SR616SW |

6.8 |

1.6 |

Diameter ±0.2mm, Thickness ±0.15mm |

321, AG3, LR616, SR616 |

|

SR927SW |

9.5 |

2.7 |

Diameter ±0.2mm, Thickness ±0.15mm |

399, AG7, LR927, SR927 |

|

SR43SW |

11.6 |

4.2 |

Diameter ±0.2mm, Thickness ±0.2mm |

301, AG12, LR43, SR43 |

|

SR1130W |

11.6 |

3.05 |

Diameter ±0.2mm, Thickness ±0.2mm |

390, AG10, LR1130, SR1130 |

|

SR921 |

9.5 |

2.1 |

Diameter ±0.2mm, thickness ±0.15mm |

370, AG6, LR921, SR921 |

|

CR2032 |

20 |

3.2 |

Diameter ±0.3mm, Thickness ±0.2mm |

BR2032, DL2032, ECR2032 |

|

CR2025 |

20 |

2.5 |

Diameter ±0.3mm, Thickness ±0.2mm |

BR2025, DL2025, ECR2025 |

|

CR2430 |

24 |

3.0 |

Diameter ±0.3mm, Thickness ±0.2mm |

DL2430, ECR2430, 5011LC |

|

CR2477 |

24 |

7.7 |

Diameter ±0.3mm, Thickness ±0.3mm |

DL2477, ECR2477, V2477 |

|

CR2320 |

23 |

2.0 |

Diameter ±0.3mm, Thickness ±0.2mm |

DL2320, ECR2320, BR2320 |

|

CR1632 |

16 |

3.2 |

Diameter ±0.3mm, Thickness ±0.2mm |

DL1632, ECR1632, BR1632 |

|

CR1620 |

16 |

2.0 |

Diameter ±0.3mm, Thickness ±0.2mm |

DL1620, ECR1620, BR1620 |

|

CR1220 |

12 |

2.0 |

Diameter ±0.3mm, Thickness ±0.2mm |

DL1220, ECR1220, BR1220 |

|

CR1225 |

12 |

2.5 |

Diameter ±0.3mm, Thickness ±0.2mm |

DL1225, ECR1225, BR1225 |

|

CR2016 |

20 |

1.6 |

Diameter ±0.3mm, Thickness ±0.2mm |

DL2016, ECR2016, BR2016 |

Major Button Cell Chemistries: Performance and Application Comparison

The performance and application scenarios of button batteries are determined by their battery chemistry. Batteries of different chemical types exhibit significant differences in voltage stability, discharge profiles, Nominal Capacity, and temperature adaptability. Among these, the discharge profile is particularly crucial, as it directly reflects the battery's power supply stability and is key to ensuring reliable device operation and extended lifespan. Another critical metric is energy density, especially for compact devices, especially for compact devices where space is limited.

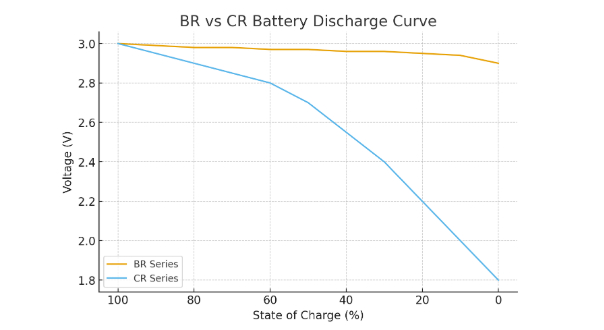

Lithium Batteries (CR/BR/LiR): The 3V Standard and Discharge Profiles

Lithium batteries, including Lithium Button Batteries and Lithium Coin Cells, with their 3V nominal voltage, have become the mainstream choice for small electronic devices. Based on their chemical composition, they are categorized into series such as CR (Lithium Manganese Dioxide) and BR, with distinct discharge curve characteristics directly tailored to different application requirements. Emerging technologies like solid-state batteries are also being explored to enhance performance and safety.

• CR Series

Employing a manganese-based chemistry, the most distinctive feature is a slightly sloped or gradually decreasing discharge curve (or a characteristic flat-then-ramp curve). It maintains a high voltage during the initial discharge phase, with the voltage gradually decreasing as capacity is depleted. This characteristic makes it suitable for scenarios requiring high current pulses, such as remote controls and small toys. Its instantaneous power supply capability meets the triggering demands of devices like IoT sensors and low-power controllers.

• BR Series

Employing a carbon fluoride system, its greatest advantage lies in an extremely flat discharge curve with minimal voltage fluctuation throughout its entire lifespan. It also offers outstanding high-temperature stability and low-temperature adaptability, enabling stable operation in harsh industrial environments. Consequently, it is more suitable for scenarios demanding extremely high power supply stability, such as industrial-grade real-time clocks (RTC) and long-term memory backup (including BIOS backup) for servers. Its lifespan can exceed 10 years, with industrial reliability significantly higher than the CR series.

• LIR Series

The rechargeable lithium battery branch employs lithium cobalt oxide or lithium polymer systems, typically with a nominal voltage of 3.7V. Its discharge curve exhibits relatively flat characteristics, maintaining good capacity stability even after 200-500 charge-discharge cycles. Its core advantage lies in its rechargeability, making it perfectly suited for small Bluetooth devices, smart wristbands, portable digital products requiring frequent recharging, and flexible runtime. This overcomes the non-rechargeable limitations of CR and BR series batteries.

Silver Oxide (SR): Stable and Precise 1.55V

Silver oxide batteries (SR series, or SR button battery) are renowned for their 1.55V nominal voltage. Their core performance advantage lies in delivering the flattest discharge curve among all button cell types, maintaining near-constant high voltage output for over 90% of their lifespan with significantly lower voltage fluctuation than other battery types. This exceptional voltage stability makes them the preferred choice for applications demanding precise power supply, s such as medical devices (e.g., blood glucose meters, electronic thermometers), high-end watches, and portable electronic dictionaries. They not only ensure accurate measurement data but also maintain precise timekeeping in devices like watches, preventing functional abnormalities caused by voltage fluctuations.

Alkaline (LR) and Zinc-Air (PR) Batteries

The LR series alkaline batteries (LR button battery) and PR series zinc-air button batteries represent two distinct categories of button cells, each targeting different market segments based on cost-effectiveness and high energy density.

• LR alkaline batteries are the mainstream choice for cost-sensitive applications. Their mature production process and low price point are offset by a significant drawback in discharge characteristics—voltage drops steadily during use, resulting in a steep decline curve. This makes them ideal for low-power devices like calculators, electronic greeting cards, and basic toys that don't demand voltage stability.

• PR zinc-air batteries achieve exceptionally high energy density through a unique chemical reaction mechanism. They generate electricity by absorbing oxygen from the air for reaction, delivering significantly more power per unit volume than other battery types. However, their operation relies on air access and demands high sealing integrity, making them primarily specialized for core applications like hearing aids, where they provide long-lasting, stable power.

Critical Interchangeability and Cross-Reference Guides

When procuring or replacing button batteries, we often fall into substitution pitfalls due to similar models or diverse codes. Minor errors may result in insufficient device runtime, while severe cases can damage precision components. This section focuses on comparative analysis of frequently confused models and provides authoritative Battery Cross Reference Chart tools to completely resolve battery replacement challenges.

CR2032 vs CR2025: Thickness and Capacity

A common question regarding CR2032 and CR2025 batteries is: "Which battery is bigger, CR2032 or CR2025?" The answer requires consideration of both physical dimensions and Nominal Capacity. In terms of physical dimensions, both CR2032 and CR2025 share the same 20mm diameter. The key difference lies in thickness: CR2032 measures 3.2mm, while CR2025 is 2.5mm thick. Consequently, CR2032 occupies a larger physical volume. This difference not only determines whether the battery fits into a device compartment but also directly impacts its core performance metric—Nominal Capacity. Specifically, the thicker CR2032, with its larger internal space, typically offers a Nominal Capacity of approximately 220 mAh. In contrast, the CR2025 has a capacity of about 160 mAh. This means the CR2032 provides significantly longer battery life. When selecting batteries, the higher-capacity CR2032 is typically recommended for products requiring long-term, stable power supply—such as smart car keys, various IoT sensors, and medical devices—to extend replacement cycles and enhance reliability. The CR2025, however, is more suitable for specific scenarios with lower endurance requirements or strict space constraints within the battery compartment.

|

Comparison Dimensions |

CR2032 |

CR2025 |

|

Diameter |

20mm |

20mm |

|

Thickness |

3.2mm |

2.5mm |

|

Nominal Capacity |

Approx. 220 mAh |

Approx. 160 mAh |

|

Suitable Applications |

Smart car keys, sensors, medical devices, and other products requiring a long-term, stable power supply |

Specific scenarios with strict battery compartment space constraints or low power endurance requirements |

LR44 vs 357/SR44: Understanding the Chemistry Substitution Risk

Many users mistakenly assume LR44 (an LR button battery) and 357/SR44 (silver oxide button batteries) are interchangeable due to their identical dimensions. Are LR44 and 357 button batteries the same? They are not identical. Despite matching dimensions, their battery chemistry differs, making unconditional interchangeability inadvisable.

• LR44 is an alkaline battery with a nominal voltage of 1.5V and lower Nominal Capacity (approx. 110–130mAh). Its voltage gradually decreases during use, resulting in a steep decline curve.

• The 357 (also known as SR44, an SR button battery) is a silver oxide battery with a nominal voltage of 1.55V and a higher Nominal Capacity (150–200mAh). It offers more stable voltage output and is suitable for devices requiring high precision, such as watches, calculators, and medical devices.

|

Comparison Dimensions |

LR44 |

357/SR44 |

|

Diameter |

11.6mm |

11.6mm |

|

Thickness |

5.4mm |

5.4mm |

|

Chemical Type |

Alkaline |

Silver Oxide |

|

Voltage Characteristics |

1.5V |

1.55V |

|

Performance Characteristics |

Its 1.5V nominal voltage suffers from a steep drop and inherent instability, making it unsuitable for voltage-sensitive circuits. |

Provides highly stable and precise voltage to ensure reliable device operation. |

While LR44 and 357 batteries can often be temporarily interchanged, long-term substitution may pose risks like voltage instability and leakage. Best practice is to use the battery type specified in the original device manual.

The Ultimate Button Cell Cross-Reference Matrix (Unique Reference)

The following table lists some IEC standard codes and their corresponding proprietary model codes from major manufacturers (Energizer, Renata, Varta), while also specifying battery types and applicable scenarios.

|

IEC Standard Code |

Renata Model |

Energizer Model |

Varta Model |

Battery Type |

Dimensions (mm, diameter × height) |

Applications |

|

SR416SW |

337 |

337 |

V337 |

Silver Oxide |

4.8×1.6 |

Small Electronic Watches, Micro Sensors |

|

SR43SW |

301 |

301 |

V301 |

Silver Oxide |

11.6×4.2 |

Standard analog watches (low power consumption), small calculators |

|

SR44SW |

303 |

303 |

V303 |

Silver Oxide |

11.6×5.4 |

Quartz watches, electronic thermometers, and small remote controls |

|

SR44W |

357 |

357 |

V357 |

Silver oxide |

11.6×5.4 |

Chronograph, backlit digital watch (high power consumption) |

|

SR512SW |

335 |

335 |

V335 |

Silver Oxide |

5.8×1.25 |

Ultra-thin microelectronic devices, hearing aids components |

|

SR516SW |

317 |

317 |

V317 |

Silver Oxide |

5.8×1.6 |

Small digital products, smart card readers |

|

SR527SW |

319 |

319 |

V319 |

Silver Oxide |

5.8×2.7 |

Portable medical testing devices, mini electronic toys |

|

SR616SW |

321 |

321 |

V321 |

Silver Oxide |

6.8×1.6 |

Ultra-thin watches, miniature voice recorders |

|

SR621SW |

364 |

364 |

V364 |

Silver Oxide |

6.8×2.1 |

Standard Quartz Watches, Electronic Key Fobs |

|

SR626SW |

377 |

377 |

V377 |

Silver Oxide |

6.8×2.6 |

Mainstream Quartz Watches, Bluetooth Headset Accessories |

|

SR69 (Identical to SR621SW) |

364 |

364 |

V364 |

Silver Oxide |

6.8×2.1 |

Small electronic meters, fitness tracker sensors |

|

SR712SW |

315 |

315 |

V315 |

Silver Oxide |

7.9×1.2 |

Ultra-thin microdevices, medical patch devices |

|

SR721SW |

361 |

361 |

V361 |

Silver Oxide |

7.9×2.1 |

Miniature electronic devices, smart wearable accessories |

|

SR731SW |

329 |

329 |

V329 |

Silver Oxide |

7.9×3.1 |

Portable Sensor, Compact Electronic Controller |

|

SR920SW |

371 |

371 |

V371 |

Silver Oxide |

9.5×2.0 |

Smartwatches, Electronic Calculators, Small Digital Photo Frames |

|

SR927SW |

399 |

399 |

V399 |

Silver Oxide |

9.5×2.7 |

Long-life electronic watches, outdoor electronic sensors |

|

SR1130W |

390 |

390/389 |

V390 |

Silver Oxide |

11.6×3.05 |

Electronic watches with multifunction buttons, miniature remote controls |

|

CR2025 |

CR2025 |

CR2025 |

CR2025 |

Lithium manganese |

20×2.5 |

Car keys, motherboard CMOS batteries, small remote controls |

|

CR2032 |

CR2032 |

CR2032 |

CR2032 |

Lithium Manganese |

20×3.2 |

Smart Door Locks, Bluetooth Gateways, Small Security Devices |

|

CR2430 |

CR2430 |

CR2430/5011LC |

CR2430 |

Lithium Manganese |

24×3.0 |

Medical devices, fitness trackers, outdoor electronic tags |

|

CR2477 |

CR2477 |

CR2477 |

CR2477 |

Lithium Manganese |

24×7.7 |

Large smart cards, wireless sensors, long-standby electronic devices |

|

CR2320 |

CR2320 |

CR2320 |

CR2320 |

Lithium Manganese |

23×2.0 |

Small portable devices, electronic organizers |

|

SR921 |

370 |

370 |

V370 |

Silver Oxide |

9.5×2.1 |

High-end quartz watches, precision electronic instruments |

|

SR1136SW |

344 |

344 |

V344 |

Silver Oxide |

11.6×3.6 |

Small electronic devices with voice functionality, voice recorder accessories |

B2B Procurement, Industrial Selection, and Regulatory Compliance

For professional procurement clients of electronic component distributors, selecting button batteries involves far more than matching specifications. It is a systematic process encompassing product performance, lifespan, mandatory safety regulations, and even factors like Blister Pack packaging for transportation and storage. Understanding market growth drivers in the battery industry also helps in making strategic procurement decisions.

Key Performance Factors for Industrial Buyers

Industrial applications demand far greater performance from button batteries than consumer-grade scenarios. Buyers must prioritize three core dimensions to ensure compatibility with production requirements.

• First is the Continuous Discharge Rate (CDR), which directly determines whether the battery can reliably support peak current demands in industrial equipment. Devices like industrial controllers and IoT sensors experience short-term current spikes during data transmission or command execution. Insufficient CDR may cause device response delays or shutdowns. Advanced testing, like High Power Pulse Characterization, can verify this performance.

• Second is cycle life, a critical metric for rechargeable button batteries (e.g., LIR series). Industrial equipment often requires prolonged, repeated charging and discharging cycles. Prioritize products with a cycle life of 200-500 cycles and gradual capacity decay to minimize long-term replacement and maintenance costs. Tools like the Self-Discharge Tester help evaluate long-term performance.

• Finally, customization requirements: Automated assembly processes in industrial production impose specific form factor demands. Features like integrated metal tabs or pins enable direct PCB soldering, while pre-installed PCM/BMS (Battery Protection Module/Management System) enhances overcharge/overdischarge protection. Terminal designs such as conical profile helical spring terminals, sheet metal spring terminals, or F ahnestock clips are also tailored to different assembly needs. These customized configurations are key to ensuring production efficiency and product reliability.

Mandatory Safety Standards: UL 4200A and CPSC Compliance

Regulatory compliance is an absolute requirement in B2B procurement, especially for the United States market. The UL 4200A standard enforced by the U.S. Consumer Product Safety Commission (CPSC), starting September 2023, directly determines market access eligibility for button or coin - or coin-shaped battery-related products.

UL 4200A is a safety standard developed by Underwriters Laboratories (UL) for non-toy products containing button/coin batteries. Following the implementation of the Reese's Law, the CPSC recognizes UL 4200A as one of the approved standards for meeting battery ingestion prevention requirements. Key requirements of UL 4200A include:

• Secure Battery Compartment: The battery compartment must be designed to prevent easy opening by children, requiring either a tool or two consecutive actions to open.

• Durability and Abuse Testing: Batteries must be securely fastened. Products must pass drop, crush, twist, and thermal exposure tests to ensure batteries do not become loose during use or misuse. When selecting suppliers, buyers must verify compliance with these standards. Additionally, considerations like transaction fees for procurement, supplier adherence to ethical guidelines. Historical manufacturers like Western Electric have set benchmarks for quality, which modern suppliers often emulate.

Frequently Asked Questions (FAQs)

To ensure the safe and proper use of button batteries, clarifying several key concepts is essential. Below are the most common questions and answers regarding battery types, positive/negative polarity identification, and model sizes.

Are Button Batteries Rechargeable?

The rechargeability of button batteries is determined by their battery chemistry, and not all models support repeated charging. The vast majority of mainstream models on the market, such as the CR series (Lithium Manganese Dioxide), LR series (alkaline batteries), and SR series (silver oxide batteries), are disposable. Forced charging may cause leakage, swelling, or even explosion risks. Only rechargeable button batteries explicitly labeled as belonging to specific series (e.g., LiR, ML, VL) possess this capability.

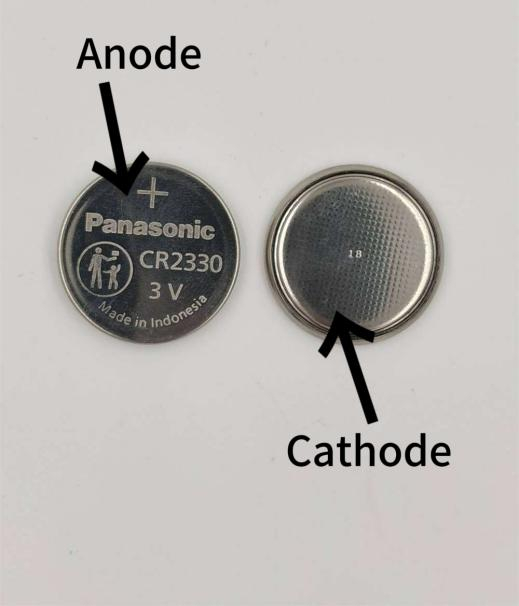

How to Tell the Positive and Negative Poles?

Identifying the positive and negative terminals of button batteries is simple and intuitive, determined by their physical structure: The flat, circular top surface is the positive terminal (typically marked with a "+" symbol), while the curved or metal-cased side and flat bottom serve as the negative terminal (some models marked with a "-" symbol). Some batteries may have markings printed in blue ink for easier identification. During installation, ensure the polarity matches the device's battery compartment—reverse installation may cause malfunctions or damage.

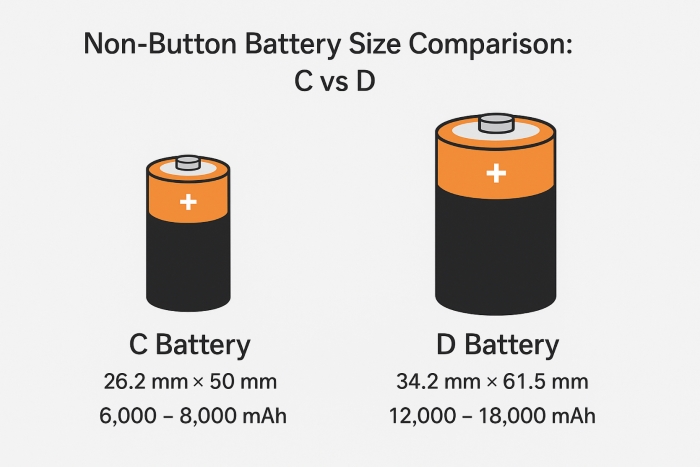

Tangential Size Comparison: C vs. D Batteries

D- cell batteries are significantly larger than C-cell batteries in both dimensions and Nominal Capacity. D-cell batteries have a nominal diameter of 34.2 mm and a height of 61.5 mm, while C-cell batteries measure 26.2 mm in diameter and 50 mm in height. D-cell batteries offer a Nominal Capacity of 12,000 to 18,000 mAh, while C batteries offer approximately 6,000 to 8,000 mAh. These larger batteries are used in high-power devices like flashlights, which may also utilize battery-assisted capacitor flash systems for enhanced performance.

Additional Technical FAQs

• voltage ratings: Button batteries typically have nominal voltages of 1.5V (alkaline, silver oxide), 1.55V (silver oxide), or 3V (lithium), with some rechargeable models at 3.7V.

• Battery Research: Advanced techniques like Electron Paramagnetic Resonance are used to study battery materials and performance.

• recycling technologies: Proper recycling of button batteries is crucial to reduce environmental impact, with dedicated processes for recovering materials like lithium and silver.

• EV Parameter Assessment: While button batteries are not used in EVs, their performance testing methods (e.g., discharge rate, temperature tolerance) align with EV battery assessment principles.

Conclusion and Procurement Recommendations

When selecting button batteries, size is merely a foundational compatibility factor—not the sole determining criterion. The operational stability, lifespan, and safety compliance of a device depend more on the precise alignment of multiple performance dimensions, including battery chemistry, discharge characteristics, and environmental adaptability. A comprehensive Product summary or grey paper from suppliers can provide detailed insights for decision-making.

Professional buyers should prioritize performance-driven solutions:

• For voltage-sensitive applications like high-end watches and precision medical devices, choose silver oxide batteries (SR series) for stable discharge.

• For industrial-grade RTCs and bios backup, BR series lithium fluorocarbon batteries offer superior reliability.

• For cost-sensitive, low-power devices, LR alkaline batteries are suitable.

• For reusable small electronics, rechargeable button batteries (LiR series) are ideal.

Safety compliance remains non-negotiable. The UL 4200A standard must be integrated throughout design and procurement. Additionally, considering the sustainability of energy sources and investing in recycling technologies aligns with modern environmental standards.

Whether purchasing consumer-grade models like consumer-grade Renata CR1632 or industrial-grade Murata CR2430, buyers should verify specifications, compliance certifications, and performance test data to ensure optimal device operation and safety.